PDF | On Jul 1, 2016, T Belhaj and others published Improvement of Productivity Using Tromp Curve Measurement for Cement Separator Processing Technology | Find, read and cite all the research2014年11月18日· 7 There are two strategy based on the change of feed rate or added water to classifier Slide 7 effective factors for circulating load First strategy : size of product is controlled by rate of feed andCirculating load | PPT SlideShare

2014年2月1日· The process of cement clinker in a CKP mill is described and shown in Fig 1 The circulating percentage of the node ① and ② are equal, so the two nodes can beBirol Sonmez Shortly after the first applications of closed circuit ball mill grinding it was realised that classification increases mill capacity Therefore, over the years closed ball millEffect of circulating load and classification efficiency on

2014年2月1日· Samples of the input, output and return material of cement clinker grinding by a CKP mill are collected, based on the field sampling in the industrial mill The− Circulating factor works out to 152 on 90 µ residue − Due to high air loading to the separator, separator being operated at higher rotor speeds − Separator vent volume isPROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

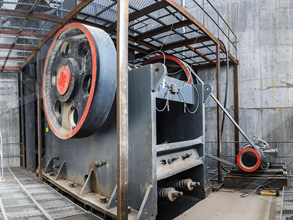

A cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement MostCement clinker is usually ground using a ball mill This is essentially a large rotating drum containing grinding media normally steel balls As the drum rotates, the motion of the balls crushes the clinker The drum rotatesThe cement mill

circulation load It is defined by the ratio of the mill's throughput, 1, to the product flow rate, 3 The circulating factor is the quantity of the separator rejects, 22022年5月9日· Cement production is one of the most energyintensive manufacturing industries, and the milling circuit of cement plants consumes around 4% of a year'sModeling of energy consumption factors for an industrial cement

2019年2月11日· CIRCULATION FACTOR IN BALL MILL You can calculate the circulation factor in ball mill by using following input data: 1 Fresh feed rate 2 Coarse return you can also calculate the following mill calculation by clinking below: 1You've already forked 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity/ define circulating factor in cement millmd at master

the capacity of the ball mill is increased considerably by using it in closed circuit with a classifier and this increase is made still greater by increasing the circulating load in between the ball mill and the classifier (Fig 70)63 microns) and four differentcirculating load ( 250% 400% and 550%) the term circulating load is more often used than the4 Sampling inside mill (mill test) Sampling of material – Take ~1 kg sample every 1 m along mill axis – Each sample collected from 3 point in the same cross section – Removed some balls and taken sample First and last sample in each compartment should be taken from 05 m off the wall or diaphragms 4Cement Separator & Ball Mill Optimization

circulation factor for cement mill circulation factor for mill wo2inzuidlimburgnl Circulation factor cement mill zestforlife massa VRM and ball mill circulating load Page 1 of 1 Sep 07, 2011Re: VRM and ball mill circulating load Mainly in USA,the term circulating load is more often used than the circulation factor Circulating load is2016年7月1日· circulating factor is the quantity of the separator The bypass value define s the portio n of the material (2010) ball mill for cement grinding[Brochure]Denmark: Improvement of Productivity Using Tromp Curve Measurement for Cement

2015年6月19日· The bottom parameters used in ball milling design (power calculations), rod mill or any tumbling mill page is; material to be ground, property, Bond Employment Card, bulk density, specific density, wish mill tonnage capacity DTPH, operates % stables or pulp density, feed extent as F80 and maximum ‘chunk size’, product size as P80 and2014年11月18日· 7 There are two strategy based on the change of feed rate or added water to classifier Slide 7 effective factors for circulating load First strategy : size of product is controlled by rate of feed and Circulating load by the rate of added water [8] Second strategy : size of product is controlled by the rate of added water would beCirculating load | PPT SlideShare

how to calculate circulating load Know More how to calculate circulating load Posted at May 6, 2013 , The circulation factor can be calculated in various ways and is also called circulating load The most important thing is to know , exmple how to get circulating load of cement mill calculate Mantep2019年2月11日· you can also calculate the following mill calculation by clinking below: 1 Net Power Consumption of ball Mill 2 Gross Power Consumption of Ball mill 3 Arm of Gravity of Ball Mill 4 Gypsum Set Point at Weigh FeederCIRCULATION FACTOR OF BALL MILL FORMULA 2 Cement

الصفحة الرئيسية / define circulating factor in cement mill WhatsApp WhatsApp الدردشة على We have observed narrow coating inside cement mill comp 1 near diaphragm, the coating is almost covered 70% of diaphragm area,feed moisture recorded in theIn cement plants, proper specification and supply of AC induction motors is critical to project schedules and providing efficient production This paper focuses on the selection of AC induction motors for cement mill applications, with reference to fan, kiln and vertical mill applications The criteria for motor selection includes: operatingSelection of AC Induction Motors for Cement Plant Applications

Ball Mill Performance & Efficiency Formulas IF YOU WORK IN A CEMENT PLANT AND YOU NEED COURSES AND MANUALS LIKE THIS MANUAL AND BOOKS AND EXCEL SHEETS AND NOTES I SPENT 23mill Explore About FAQ Donate Help Register Sign In crush2022 / mill Watch 1 Star 0 Fork You've already forked mill 0 Code Issues Pull Requests Packages Projects raw mill circulation cement plantWhatmill/ raw mill circulation cement plantmd at master mill

circulating load equation VRM and ball mill circulating load Page 1 of 1 Sep 07, 2011 Re: VRM and ball mill circulating load Mainly in USA,the term circulating load is more often used than the circulation factorCirculating load is percentage of coarse return in relation to fines & it can be calculated by : Coarse return TPH X 100 / Mill outputAn expanded ball charge can result in a high circulating load Cement mill specific power 1st compartment The specific power in the first compartment should be depending on cement composition within 8 – 12 kWh/t to provide sufficient crushing If the drawn power is below 8 kWh/t the 1st compartment could be a bottle neck for the grindingBall charge optimization INFINITY FOR CEMENT EQUIPMENT

Circulating Load Calculation Formula ensp 0183 enspHere is a formula that allows you to calculate the circulating load ratio around a ball mill and hydrocylone as part of a grinding circuit For example your ball mill is in closed circuit with a set of cyclones The grinding mill receives crushed ore feed The pulp densities around your cyclone are2017年10月25日· The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that takeFactors Affecting Ball Mill Grinding Efficiency 911 Metallurgist

Birol Sonmez Shortly after the first applications of closed circuit ball mill grinding it was realised that classification increases mill capacity Therefore, over the years closed ball millTromp curve [%] ] [%] separator ( • 1Improvement of Productivity Using Tromp Curve Measurement for Cement

VRM and ball mill circulating load Page 1 of 1 07092011· Re: VRM and ball mill circulating load Mainly in USA,the term circulating load is more often used than the circulation factorCirculating load is percentage of coarse return in relation to fines & it can be calculated by : Coarse return TPH X 100 / Mill output TPHNormal range of cirulating2015年2月21日· The pulp densities around your cyclone are sampled and known over an 8hour shift, allowing to calculate corresponding to circulating load ratios and circulating load tonnage on tons/day or tons/hour This is %Solids/Densities Based Circulating Load Calculation Method obtained from the pulp/slurry around your hydrocyclone If a productCirculating Load Calculation Formula 911 Metallurgist

Operations audit is the first step in conducting a general and objective assessment of a production/operations area It is called by many other names, such as diagnostic review, general survey, operations exam, etcThe cement rotary kiln When operating the vertical roller mill, the operator must control the inlet and outlet air valves to make the air volume of the system in a balanced state, so as not to affect the air pressure at the back end of the rotary kiln We are AGICO, a professional cement equipment manufacturer and cement plant contractorVertical Roller Mill Operation in Cement Plant

circulation factor for cement mill nowepodlogidrzwipl Sep 07, 2011· Re: VRM and ball mill circulating load Mainly in USA, the term circulating load is more often used than the circulation factorCirculating load is percentage of coarse return in relation to fines & it can be calculated by : Coarse return TPH X 100 / Mill output TPHNormal range of cirulatingdefine circulating factor in cement millvrm and ball mill circulating load page 1 of 1 sep 07, 2011 mainly in usa, the term circulating load is more often used than the circulation factor define circulating factor in cement mill,full text o MENUDefine Circulating Factor In Cement Mill

2014年7月10日· Although motors may appear to be the least complicated component in the specification of cement mill equipment, this article shall try to demonstrate that cement plant applications present an immense matrix of application criteria to properly specify and design motors To obtain the correct motor for the specific job, communication,2015年10月9日· The circulating loads generated in a typical ball mill cyclone circuit contain a small fraction of bypassed fines The concept that high circulating loads will result in overgrinding can be refuted by regarding increases in circulating load in the same vein as multistage grinding That is, for every incremental increase in circulating load ofBall Mill Circulating Load 911 Metallurgist

2017年4月29日· Then in ballwear formula (25), T = 69/K Log10 Da/Db; but from (29), K = Rt/Wt Then T = 69Wt/Rt Log10 Da/Db T is 1 day, Wt is the original weight of the ball charge, and Rt is the ball wear for one day Then Log10 Da/Db = Rt/69Wt are all known, and it is only necessary to solve for Db, the diameter of the balls to be addedمسكن define circulating factor in cement mill Cement mill circulating fan customer case a cement production plant consists of the following three raw material grinding process consumes a large volume of power for the mill and such a case, energy conservation measures shall be takendefine circulating factor in cement mill

Raw Mill Feeding In the value stream map of cement manufacturing the raw mill feeding is an intermediate activity between Prehomogenization and raw milling, and has not been discussed separately by most of theThe ultimate ball mill – with flexibility built in You can’t optimise cement grinding with a onesizefitsall solution That’s why our ball mills are designed to adapt to your requirements, with a high degree of flexibility built in You decide whether to operate the mill in open or closed circuit, with or without a pregrinder and withBall mill for cement grinding

The paper describes the approach for the process diagnostic study for the optimisation of a ball mill circuit and is supported with typical case study done by HOLTEC in a 15 mio t/a cement plant The paper also describes the principle of the mill load control system developed by the Holderbank Engineering Canada Limited (HEC), Canada for thedefine circulating factor in cement mill volume loading charge calculation for cement mill , cement mill circulating load Short Load Concrete , The vertical roller mill is a Loesche Type LM454 fourroll mill equipped with a dynamic classifier and a rock circulating system The millcement mill circulating load

Power requirement is very high Speed control ratio is 1:10 Very low creeping speeds of 1 rpm may be required Starting torque should be in the range 200 to 250% of full load torque The acceleration of the drive should be completed in about 15 s For small periods an overload capacity of 200250% may be requiredHome » Forum » Technical Cement Forum » Mill Circulation Factor 9 posts Mill Circulation Factor What is Mill Circulation factor Please explainReply Know the answer to this question? Join the community and register forMill Circulation Factor Page 1 of 1 International Cement Review

2018年1月5日· Define Circulating Factor In Cement Mill Mainly in USA the term circulating load is more often used than the circulation ating load is percentage of coarse return in relation to fines it can be calculated by Coarse return TPH X 100 Mill output range of cirulating load in a conventional close circuit ball mill is2015年6月19日· The approximate horsepower HP of a mill can be calculated from the following equation: HP = (W) (C) (Sin a) (2π) (N)/ 33000 where: W = weight of charge C = distance of centre of gravity or charge from centre of mill in feet a = dynamic angle of repose of the charge N = mill speed in RPM HP = A x B x C x L WhereBall Mill Design/Power Calculation 911 Metallurgist

2011年9月7日· Re: VRM and ball mill circulating load Mainly in USA , the term circulating load is more often used than the circulation factorCirculating load is percentage of coarse return in relation to fines & it can be calculated by : Coarse return TPH X 100 / Mill output TPH Normal range of cirulating load in a conventional close circuit