What is a gold processing plant? Mined goldbearing ore containing gold and silver is extracted and purified through a processing plant In this gold recovery plant, the precious metals are extracted from the ore through aGold Processing Plants & Complete Ore Process Plant Mineral Processing Plants Gold, Silver, Copper, Zinc, Lead, etc, Ore NO Chemical Gravity Gold Recovery Equipment Gravity Gold & FlotationGold Processing Plants & Complete Ore Process Plant

2020年5月17日· Goldplat announced this week that it had not only completed a “Stage 2” expansion of a new processing plant at itsGold Processing Modular Plants: Gold Processing Trusted Independent Committed Innovative Technological Solutions SGS Bateman Engineering Services modular plantsModular Plants: Gold Processing

269 行· 2016年1月1日· Abstract Operational and development issues regarding various gold plants and processes detailed in Gold Ore Processing, Second Edition, are2017年9月7日· Gold processing 101 Alan Riles looks at the primary flowsheet selection drivers for gold concentrators Alan Riles 07 September 2017 Amidst the general fall inGold processing 101 miningmagazine

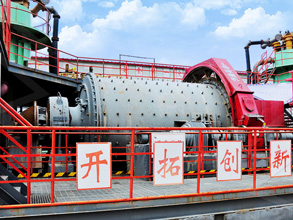

China Gold Ore Processing Plant wholesale Select 2024 high quality Gold Ore Processing Plant products in best price from certified Chinese Mining Equipment2020年7月18日· Rock Gold Plant The plant mainly includes four parts: First part is crushing, typically by two or three stages of crushing, like primary jaw crusher, secondaryRock gold processing plant, gold ore processing plant | Henan

2016年5月25日· This arrangement and flowsheet of a Mini Portable Gold Processing Plant permits several mineral separations by flotation and provides for the possible recovery of other minerals by gravity2023年11月19日· Prep the item by using the kit's cleaning solution If you don't have the solution, buff the item with a household degreaser and rinse it off with water Coat the item with an activating solution and rinse withHow to Gold Plate: 13 Steps (with Pictures) wikiHow

At the same time, we provide various ore flotation process solutions, it also suitable for sulfide silver, zinc, lead, fluorite ore, and copper flotation processing plants The beneficiation plant efficiency and the recovery2021年3月18日· The CIP gold processing plant mostly uses the heating and pressure desorption method to desorb the goldloaded carbon The concentration of the desorption solution is NaCN 1%, NaOH 1%, the desorption temperature is 135°C, the desorption is performed at 310KPa pressure for 1418h, and the flow rate of the desorption solution isHow Does A CIP Gold Processing Plant Work?

process for a large simple base metals mineral processing plant covering the required range of processing rates for the example described above In this example a contingency of 20% was allowed and represents the lower limit of the range of contingency allowances applicable to a properly conducted scoping studyGold CIP Processing The gold CIP ( CarboninPulp ) is widely used to extract gold from ore It mainly involves using activated carbon to adsorb gold from a cyanide solution, then eluting and regenerating the carbon for reuse It is mainly suitable for beneficiating goldcontaining oxidized ore with high slime content and containing carbon oreGold CIP Processing Solution JXSC Machinery

2016年3月18日· The savings made in lower operation costs and lower maintenance costs are noticeable and this saving was also made in the face of a 125% increase in wages made when the new plant was started Buy a Gold Processing Plant Many of our socalled small gold mines or low grade deposits could well take this simple and inexpensive2022年8月1日· Golden Spur Resources Pty Ltd – a wholly owned subsidiary of Bellevue Gold Limited – has awarded an $878 million engineering, procurement and construction (EPC) contract to GR Engineering Services Limited (GRES) This contract award will get GR Engineering to undertake the delivery of the 10Mtpa gold processing plant andGR Engineering secures EPC contract for Bellevue Gold processing plant

Goldplated aluminium cover on Voyager space craft that protects a goldplated Sounds of Earth record A gold plated desktop Stirling engine Gold plating is a method of depositing a thin layer of gold onto the surface of another metal, most often copper or silver (to make silvergilt), by chemical or electrochemical platingPlating refers to modern coatingCargill will produce wheat for use in products such as sweeteners and protein The plant will process 750,000t of wheat per year The Cargill plant in Manchester will now process wheat instead of corn/maize Cargill is one of the largest privately owned grain processing companies in the world The US company’s activities include purchasingCargill Wheat Processing Plant, Manchester

Savona Equipment is your source for new, used, and reconditioned Ore & Mineral Processing Plants of many types and capacity for large primary ore processing, secondary, and tertiary fine material concentrating as well112 patents technologies, more than 500 mineral processing plants in the world Xinhai currently has 112 patents technologies, the gold dressing plant projects spread among China, Southeast Asia, South America, Africa,CIL Gold Processing Plant

During the design phase, potential processing routes are identified and evaluated to optimise gold beneficiation of the particular gold bearing ore Modular plants offer a complete solution from runof mine (ROM) reception, primary and secondary crushing, milling, gravity concentration when appropriate, flotation when appropriate and2022年10月9日· The application of CIP or CIL gold processing plant CIP or CIL method is suitable for processing the oxidized gold ore with high slime content 3 Confirm the capacity In this step, you shall consider how many ton of gold ore you will process per day or per hour, such as 100t/d, 200t/d or 300t/d, etc This is the foundation of design a CIPCIP or CIL gold processing plant designZJH minerals

Multotec's Gold Industry Flow Sheet We use cookies to improve your experience on our website By using our site you agree to Cookies Policy2015年5月14日· Editor’s Note: In our last article, Calla Gold, a Santa Barbara jeweler specializing in custom jewelry design and jewelry repair, described gold plating and its best practices In this article, she describes the stepbystep process How Gold Plating is Done, Step by Step by Calla Gold Gold plated – sometimes called electroplated – items areHow Gold Plating is Done, Step by Step Thermo Fisher Scientific

With more than 300 gold processing plants/projects, designed, built and commissioned within Australia, since the early 80’s, coupled to the current large number and diverse range of off shore developments Australia is probably without rival for fast tracking Fixed Lump Sum or Cost Plus(EPCM) and Turnkey projects for goldGBI was initially contracted by Oceana Gold to provide 18 process tanks for a new processing plant at their Haile Gold mine located in South Carolina M3 Engineering was assisting Oceana as advising engineer Once on site, GBI's crews were immediately recognized by Oceana and M3 for their excellent safety, quality and work ethicGold Mine Process Plant | Great Basin Industrial

As a Plant Operator at MMG GOLD LIMITED, I apply my chemical and process engineering skills to operate and maintain the plate and frame press filtration systems I am responsible for ensuring the quality and safety of the gold extraction process, as well as troubleshooting any issues that arise | Learn more about RAMADHANI MOHAMED's work experience,operations and metallurgical team has allowed the processing plant to achieve above the name plate design at 102 t/h and recoveries in the order of 928 per cent for gold and 884 per cent for copperOptimisation of the Peak Gold Mine’s Processing Plant through

Elution and Goldroom plant The minevik Elution and Goldroom plant can be delivered standalone or as part of a holistic gold process solution to enable onsite production of gold doré The elution plant is built from pre2016年1月23日· Gold Process Description In our Gold Process Description EXAMPLE, the ore will be received by the crushing plant initially by rail haulage from the ABC Zone and later by truck from theGold Process Description 911 Metallurgist

Mining Method and Processing Côté Gold’s processing plant incorporates triedandtested technology integrated with novel uses of established processes Ore processing capacity Total recovered gold: 918% Processing Flow Sheet 1 Crushing 1 Crushing A fleet of autonomous haulers feed the primary and secondary C steel plate processing machines are used to manufacture steel plates to precision tolerances for use in a wide range of applications Steel plate fabrication systems include pullthrough and gantrystyle plate processing machines, and plate duplicators These machines carry out precision drilling, scribing, tapping, countersinking, millingPlate Processing | Ficep UK Ltd

So is the headgrade of gold used in the batch leach test (g/ton) Sm is the ultimate residue value ie the gold concentration in the residue after an ‘infinite’ period of leaching In this case, 80 hours of batch leaching is a good approximation to infinity This value will vary as2014年2月1日· All Hgcontaminated tailings are leached with cyanide Many processing plants continue to dump their final cyanidation tailings into the local rivers Over 880,000 tonnes of tailings and mining waste are estimated to enter the Puyango River annually, containing about 650 kg of Hg and 6000 tonnes of cyanide (Guimarães et al, 2011)Processing centres in artisanal gold mining ScienceDirect

Gold processing solutions from Multotec ensure your beneficiation plant is optimised for the lowest cost per ton! With equipment covering each stage of the beneficiation process, from ROM stockpile to processed mineral and tailings, Multotec enables you to achieve your gold processing goals! Our equipment solutions for Gold Processing include:The minevik Outotec Gold Refining Plant is the result of more than 30 years’ experience in developing robust and costefective solutions for precious metals recovery and refining The process has been successfully applied worldwide in installations with annual gold refining capacities from 1 to 50 tons The gold refining process is purelyminevik Outotec Gold Refining Plant

The gold carbon in pulp (CIP) Processing refers to the process of grinding all the gold ore into a slurry (200 mesh content accounts for more than 9095%) Cyanide leaching was carried out first, then activated carbon was used to absorb the Gold loaded carbon from the pulp, purification and smelting of the goldloaded Gold in the medium2020年12月1日· Niquini and Costa used neural networks to forecast yield and metallurgical recovery of all plant outputs in a gold [15] and a zinc [14] processing plants The results showed that neural networksForecasting mass and metallurgical balance at a gold processing plant

This Manual is basically concerned with process description of Vat Leaching and elution process of gold extraction The report is tailored to all stakeholders so as to provide an overview and understanding of the2023年1月31日· 1 Nigeria 80 TPH alluvial gold & placer mine processing plant Nigeria gold processing plant processed the mudcontaining alluvial gold and placer gold ore, mostly in the form of particles Its productionGold Processing Plants in Nigeria, South Africa and

2016年2月29日· If the solution is rich enough can be treated by zinc powder and the precipitated obtained (cement) obtained will be sent to retorting and smelting For gold extraction the strength of cyanide solution ranges fromIn this article, we present laboratory scale batch grinding and leaching profiles of a monosized gold ore sample (1700 + 850 μm) The sample was obtained from a runofmine (ROM) ore of one the leading gold processing plants in South AfricaVAT LEACHING AND ELUTION PLANT GOLD PROCESSING TECHNOLOGY

South African Office Daveyton Road, PO Box 40, Benoni 1500, South Africa Tel: +27 (0) 11 749 6300 Fax: +27 (0) 11 749 6324Resources Modular Gold Plants (MGP) are complete turnkey modular gold plants designed for the 500 to 2000 ton per day producer Permitting requirements and land disturbance are minimized as a result of the inherent environmentally friendly processing technology and compact footprint of the Modular Gold PlantsModular Gold Plants Proprietary Resources Gold Technology

Alluvial gold washing plant / 90%+ Gold Recovery Ratio Alluvial gold ore is a type of placer deposit that contains gold particles that have been eroded from their original source and transported by water and deposited in a new location Alluvial deposits can be found in riverbeds, floodplains, and other areas where water flow is prevalent12M DIAMETER THICKENER12M DIAMETER THICKENER FOR SALEThickens slurry and dewatersIdeal for processing circuits in gold, coal, base metals, platinum , graphite projects, etcCan be used after milling plant, or before slimes damUnit is almost complete and built newTank diameter: 12mTank Depth: 36 mDrive motor: 3 kWRake Speed: 019Gold processing plant Ads | Gumtree Classifieds South Africa

1 Rock Manganese Ore Processing This setup is for the rock manganese ore processing plant, main equipment and flow including: The raw bin+vibration feeder for feeding materials to the jaw crusher automatically, you only need to load the materials to the raw bin by truck or excavator or else as you want The jaw crusher is for crushing the rawFollowing his keynote presentation at AusIMM’s recent Gold Plant of the Future Symposium, the AusIMM Bulletin caught up with Kenneth deGraaf, ’s Global Product Line Manager, Downstream Gold Recovery Products, to discuss the latest technologies and approaches in gold plant processingThe gold plant of the future