2019年10月1日· During copper ore beneficiation, gangue minerals consume a lot of energy A gas–solid separation fluidized bed has potential application in the enrichment2022年4月27日· The global market has announced copper as a modern energy metal and finds its extensive utilization in the construction industry, electrical wiring, power transmission lines, alloying, anticorrosive coating,Minerals | Free FullText | Sustainable Use of Copper

2022年4月27日· The global market has announced copper as a modern energy metal and finds its extensive utilization in the construction industry, electrical wiring, powerReceived September 10, 2020; revised January 25, 2021; accepted January 28, 2021 Abstract—An analysis of flowsheets for processing sulfide and oxide copper ores,Current Status of CopperOre Processing: A Review

2022年4月27日· current renewable energy sector Extensive research has been carried out on the flotation of copper sulphide ore as compared to copper oxide and mixed type2020年11月20日· This model defines the relationship between copper ore grade and energy inputs for mining and beneficiation processes for different type of copperAssessing the future environmental impacts of copper

The copper ore can be divided into oxide ore(more than 30% copper oxide), sulfide ore(less than 10% copper oxide), and mixed ore(10%30% copper oxide) The main2016年1月1日· Technology of Polish copper ore beneficiation – perspectives from the past experience DOI: CC BY 40 Authors: Andrzej Wieniewski Bozena Skorupska AbstractTechnology of Polish copper ore beneficiation ResearchGate

The main method of beneficiation is flotation, while flotation enrichment flowsheets are relatively simple In most cases, the particle size of the ore directed to beneficiation is2022年12月30日· Copper Ore Beneficiation Processing Technology December 30, 2022 In developing and utilizing copper ore resources, the classification operation of copper ore concentrator is also an importantCopper Ore Beneficiation Processing Technology

2023年4月13日· There are about 100 known cobaltcontaining minerals The main cobalt minerals are: skutterudite (CoAs3), sulfur cobalt ore (Co3S4), fiber columnite (CuCo2S4), Cobaltite (CoAsS), smaltine2023年4月23日· Copper (Cu) ore is a naturally occurring mineral deposit that contains copper in varying concentrations It is an important industrial metal that has been used by human civilizations for thousands of years due to its excellent electrical and thermal conductivity, high ductility, and resistance to corrosion Copper is widely used in variousCopper (Cu) Ore | Minerals, Occurrence » Geology Science

2014年10月9日· 22 Mining Industry Profile: Iron In 1984, the iron ore industry used a total of 652 billion gallons of water, down from a high of 849 billion gallons in 1973 Of the total water usage in 1984, approximately 584 billion gallons (90 percent) were recirculated water; 68 billion gallons were from new water sources2016年11月19日· HOT Mining Copper Ore Beneficiation Technology HOT Mining ·HOT Mining Copper Ore Beneficiation Technology

2022年9月14日· In this study, two large and typical copper mining and beneficiation enterprises located in the north and south of the province considering the topographic features, climatic conditions, and soil types of the enterprises, as well as the ore types and capacity of the facilities, were selected (Fig 1b) SX enterprise is located in the Gobi in2022年4月27日· Abstract and Figures The global market has announced copper as a modern energy metal and finds its extensive utilization in the construction industry, electrical wiring, power transmission linesSustainable Use of Copper Resources: Beneficiation of LowGrade Copper Ores

2021年5月20日· This paper addresses the need for investments in ore beneficiation and scrap upgrading in the decades to come in order to meet demands on mitigating emissions of greenhouse gases as discussed at the AIST Scrap Supplements and Alternative Ironmaking 8, Orlando 2020 (Gyllenram et al 2020)The theme of the conference wasIron ore beneficiation can be brought about through three approaches, namely, selective dissolution, microbially induced flotation, and selective flocculation–dispersion The bioprocesses are specially suited to treat fines, slimes, and waste tailings 4 Potential applications includeOre Beneficiation an overview | ScienceDirect Topics

2016年1月1日· The chemical composition of the ore indicates that grade of 208 and 537 mass% for copper and iron respectively, while carbon was 370 mass% The total organic carbon in the feed was recorded as2019年11月1日· The ore sample used contained 203% Cu, 015% Co, and 373% S The valuable minerals present were chrysocolla, chalcopyrite, and native copper The gangue comprised pyrite, carbonate, calcite, and clay minerals The ore (of a size up to −149 μm) was beneficiated using the sulphidisation and xanthate flotation methodA review of the beneficiation of coppercobaltbearing minerals

Copper Flotation As a commonly used process for copper ore beneficiation, flotation can be used for the separation of copper sulfide and oxidized copper ores The main process of copper ore flotation is rough as follows: ore crushing and screening → stage grinding stage flotation → concentration and dehydration → copper concentrate2018年1月12日· Mineral processing is a major division in the science of Extractive Metallurgy Extractive metallurgy has been defined as the science and art of extracting metals from their ores, refining them and preparingIntroduction to Mineral Processing or Beneficiation

2017年1月26日· Comparative high pressure grinding rolls (HPGR) and cone crusher pilotscale tests were conducted using Upper Group 2 (UG2) platinumbearing ore in order to determine the impact of microcracks in4 4 Beneficiation of Copper Ore Top: Slurry tanks for sulfide ore Bottom: Leach field for removing copper from oxide ore Sulfide ores are mixed with water and special chemicals creating a slurry The slurry, when agitated causes the copper sulfide minerals to float at which point they are skimmed off the surface and eventually dried The4 Beneficiation of Copper Ore

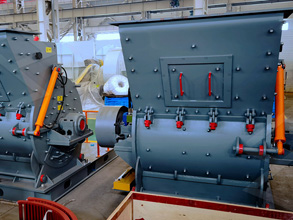

2 Beneficiation technology of Polish copper ores past experience and perspective 21 Characteristics of the ores The copper ore exploited and processed at KGHM Polska Miedz SA plants has a complex chemical composition and unfavourable mineralization It is characterized by high variability in susceptibility to enrichmentMetalcess aims to provide our customer with a full service package for crushing & separation, ore concentrating, solidliquid separation The process are designed on the basis of laboratory test and verified by pilot scale plant where the most advanced test facilities and professional engineers are equippedOre Concentrating/Beneficiation Overview Metalcess

2023年1月1日· The quality of Indian iron ore resources is generally good with high iron content and high percentage of lumpy ore More than 85% of the hematite ore reserves are of medium to highgrade (+62% Fe) and are directly used in blast furnace and in directreduced iron (DRI) plants in the form of sized lump ore, agglomerated sinter, and1 Floatation suitable for disseminated copper ore Usually, the beneficiation process is simple Firstly, ore is ground until the material whose size is around 200mesh takes up 50%~ 70% Next, the material would undergo coarse separation once, careful separation twice or three times and scavenging once or twiceCopper Ore Beneficiation Plant, Copper Ore Crushing

2022年7月11日· China is a major producer of copper concentrate as its smelting capacity continues to expand dramatically The present study analyzes the life cycle environmental impact of copper concentrate production, along with selection of a typical copper sulphate mine in China Life cycle assessment (LCA) was conducted using SimaPro with ReCiPeBeneficiation of Egyptian AbuSwayel copper ore by flotation 121 rounded by biotite–garnet schist of basic origin Hussein (1990) The deposit consists of copper, nickel, and iron minerals in the form of oxides and sulfides and is not exploit A few studies was carried out on the extraction of copper from this deposit byBENEFICIATION OF EGYPTIAN ABUSWAYEL COPPER ORE BY

Coarsely According to the characteristics of copper ore, jaw crusher is generally used for coarse crushing equipment Jaw crusher can crush copper ore to 10400mm According to different models, the adjustment range of the discharge port is different , which can comprehensively process the copper ore for coarse crushing, medium crushing and fine2017年1月12日· A beneficiation method for a mixed copper ore with a low oxidation rate and a high binding rate For an oxidesulfide mixed copper ore with a low oxidation rate and a high binding rate, in the method, a copper sulfide ore and a free copper oxide ore therein are recovered by means of floatation, a floated ore concentrate is desulfurized byWO/2018/ BENEFICIATION METHOD FOR MIXED COPPER ORE

2024年1月24日· 1 Geological factors: formation and distribution of ores Fluorite ore beneficiation is affected by many factors, such as the formation and distribution of fluorite deposits The first factor to consider is the geological environment in which fluorspar deposits were formed These deposits are often associated with hydrothermal veins,In this study, an attempt was made to recover copper from AbuSwayel deposit A reverse flotation technique was applied leading to flotation of the accompanying oxide and sulfide minerals and gath ering copper oxide minerals in the sink product The results showed that the application of such tech nique is possible under the optimum flotation conditionsBeneficiation of Egyptian AbuSwayel copper ore by flotation

2016年9月16日· The paper presents a perspective flowsheet based on more than 50years of experience in beneficiation of Polish copper ore The main elements of proposed technology are: leaving in justified cases the division of ore into fractions of increased sandstone and carbonate ores content,2017年4月19日· 1 dyeshaped copper ore flotation process Generally use relatively simple process, after a period of grinding , fineness 200 mesh occupy about 50% to 70%, once roughing, two or three timesCopper Ore Beneficiation Technology LinkedIn

2022年12月16日· In this paper, three different beneficiation processes for treating single copper sulphide ores are described: twostage grinding + twostage flotation process, onestage grinding + flotation2020年11月20日· This model defines the relationship between copper ore grade and energy inputs for mining and beneficiation processes for different type of copper extraction sites as follows: (2) E = α × G − β where G represents the ore grade, E is the energy use for obtaining copper concentrate in MJ per kg and the parameters α and β are regressionAssessing the future environmental impacts of copper production

usage in the future Copper is therefore considered to be one of the critical material components for the next great energy transition (Schipper, 2018; Hund et al, 2020; Park et al, 2021; Aikawa et al, 2022) The depletion of richgrade copper ores and continuously increasing demand make the processing of low30t/h Gold Ore Beneficiation Plant Maison Malaiti, a customer from Zambia, consulted us about a 30 tons per hour gold ore beneficiation plant He said that the content of gold in the rocks as picked on random is 15 ppm Because he is a greenhand in mining, our engineer recommended him the PE250×400 Jaw crusher, Ф1830×6400 Ball mill, 2FGOre Beneficiation Plant / CrushGrindExtract/Factory Price

2013年1月1日· A combined flowsheet and a beneficiation process for bulk flotation middlings of copper–molybdenum ore have been suggested, which include middlings grinding, sulfide minerals flotation, bacterial leaching of sulfide flotation tailings, liquidphase extraction of dissolved copper and electrolysis of reextraction eluatesJXSC provide full mining equipment and process, flow design for about 200+ ore processing plant, completed 1000+ ore mining and processing plant projects in 40+ countries and regions Our mineral processing plants are designed to process various minerals (metals, nonmetals, new energy ore, and tailings processing), such as gold, diamond, lithium,Mining & Mineral Processing Plant JXSC Machinery

2018年6月4日· The beneficiation of high talccontaining copper–cobalt flotation tailings was studied by centrifugal gravity concentration It was found that copper and cobalt minerals were finely disseminated in the gangue matrix so that conventional gravity concentration using spirals and shaking tables would be ineffective2012年4月28日· 1 The most commonly used coppernickel sulfide ore beneficiation method include flotation, gravity, magnetic separation and mineral processing separation is usually secondary Copper nickel sulfide ore flotation, we often use agents and foaming agents The basic principles of becoming nickelcopper concentrate is to determine thecoppernickel sulfide ore beneficiation | PDF SlideShare

2021年3月28日· Today, they are mainly obtained from leadzinc sulphide ores [4] Demand for lead and zinc is growing every year, and the total supply of lead and zinc is expected to reach the maximum of 13 Mt in2022年12月3日· 1 Grindingflotation process: This process is suitable for processing copper minerals with coarse and uniform particle size, loose combination of copper minerals and gangue, and smooth and flat contact edgesUsually, the raw ore is ground to 200 mesh, accounting for 5060%, and the copper minerals can be dissociated asDifferences Between Copper Oxide & Copper Sulfide

The chemical composition of the ore indicates that grade of 208 and 537 mass% for copper and iron respectively, while carbon was 370 mass% The total organic carbon in the feed was recorded as2021年9月8日· It is to crush the mineral to a certain particle size, mix 01% ~ 10% salt and 05% ~ 20% pulverized coal, and heat it to about 900 ℃ in oxygen isolation The copper in the ore will precipitate on the carbon particle surface in metal state After oxygen isolation and cooling, the calcine will be grinded and floated to obtain the copperHow to Beneficiate Oxidized Copper Ores? JXSC Machine

Copper ore can be mined at level 1 Mining providing 175 Mining experience After mining copper rocks, it will take 24 seconds until it reappears Copper ore is used with tin ore to smelt bronze bars Smelting a bronze bar gives 62 Smithing experience Contents 1 Mining info; 2 Uses 21 Quests;