2018年1月12日· There are three primary types of runofmine materials: Runofmine consisting of useful materials These could include granites,Mineral processing or mineral beneficiation or upgradation involves handling of three primary types of ROM ore material which has been blasted, fragmented and brought outMineral Processing an overview | ScienceDirect Topics

The quartz ore beneficiation process is to crush the mined quartz ore The qualified materials crushed by the crusher are evenly sent to the inside of the quartz ore ball mill through the elevator and the ore feeding equipment2021年3月12日· Magnetite Beneficiation or ore dressing production line combined by vibrating feeder, jaw crusher, vibrating screen, ball mill, classifier, magnetic separator,Magnetite Beneficiation Mining and Mineral Processing

2022年2月23日· It can be applied toward the design, construction, maintenance, control, performance monitoring, and operation optimization of processes like crushing,Beneficiation Extraction of Lanthanides from Spent Polishing Agent Alexander Poscher, The beneficiation and obtainment ofReserves Base Mineral beneficiation beginsBeneficiation an overview | ScienceDirect Topics

Mineral beneficiation is a process by which valuable constituents of an ore are concentrated by means of a physical separation process As one of the initial steps of extractive metallurgy, the main purpose is to prepare theSCRUBBING Scrubbing is the process whereby clays, slimes and any potential oxidization present in or on the ore typically using water Scrubbing conditions the ore surface forSGS MINERALS SERVICES – T3 SGS 960 112009

There are seven basic comminution circuits that can be used to prepare beneficiation feed from the product of a primary crusher This paper gives a comparison of these circuits2013年8月9日· Mineral Ore Beneficiation Methods Beneficiation means the following asapplied to iron ore: milling (crushing and grinding), washing, filtration, sorting, sizing, gravity concentration, magnetic separation,Mineral Beneficiation Plant | Mining, Crushing,

2024年1月24日· 1 Hand Separation method In the 1950s and 1960s, manual beneficiation was one of the main beneficiation methods in the production of lithium concentrate and beryl concentrate at home and abroad For example, in 1959, the handselected beryl concentrate in Xinjiang, Hunan and other provinces and regions in myMineral Processing Swapan Kumar Haldar, in Mineral Exploration (Second Edition), 2018 13243 InStream Analyzer and Process Control Mineral beneficiation, particularly base and noble metals, is sensitive to optimum use of reagents, recovery of metals, and clean concentrateHigh fluctuation of feed grade at flotation cells yields loss of metals to tailingBeneficiation an overview | ScienceDirect Topics

Precious metals minerals processing plant refers to gold, silver, diamond and platinum group metals, especially the gold mining and peocessing plant inclding flotation and gravity separation, CIL, CIP process, etc We are ore processing plant and equipment supplier from China, with over 35 years of rich experience in beneficiation, support custom mineralForui Machinery has more than 20year experience in ore dressing equipment Forui is specialized in manufacturing metal&nonmetal mining machinery like jig separator, magnetic separator, dewatering screen, gold extraction equipment, tin extraction machine and other mineral separator Contacts: : sales1@frjig Tel: 86371Jig Concentrator|Roll Crusher|ore washing machine|vibrating

Mineral beneficiation is a process by which valuable constituents of an ore are concentrated by means of a physical separation process As one of the initial steps of extractive metallurgy, the main purpose is to prepare the ore prior to downstream purification processes The most common mineral beneficiation processes include: sampleOver 5 decades, MINERAL PROCESS EQUIPMENT PVT LTD, has evolved as a progressive manufacturing company, adding value to the mines & mineral processing industry with costeffective design, manufacture and supply of worldclass mineral processing equipment Engineering machines to increase operating efficiency and cut costsMineral Process Equipment India Pvt Ltd, Mumbai, India

Zircon sand beneficiation is removing impurity minerals from zircon sand ore and increasing the content of zircon sand ore We determine the beneficiation process and equipment configuration according to the zircon placer’s specific mineral composition and properties The common zircon sand beneficiation process is a composite beneficiationcopper Processing Plant 1 Copper flotation process The setup is complete copper flotation plant; main equipment and process details as follows: 1 Crushing: Adopts twostage opencircuit crushing and selects jaw crusher for crushing, and the crushed product is transported to fine jaw crusher for twostage crushing 2Copper Beneficiation Process, Equipment JXSC Machinery

field of Mineral Beneficiation Star Trace manufactures & exports the following equipment which are used for mineral beneficiation in laboratories:Jaw Crusher, Roll Crusher, Ball Mill, Vibratory Cup Mill, RoTap Sieve Shaker, Riffle Sample Splitter, Davis Tube Tester,Hydrocyclone, Mineral Jig, Concentrating Table, Spiral Test Rig, WHIMS,MineralLithium beneficiation processing plant includes crushing, grinding, gravity separation, flotation, magnetic separation and combined process According to the nature of lithium ore (spodumene, lepidolite, lithium feldspar),Lithium Processing Plant, Equipment JXSC Machinery

2024年1月24日· Copper industrial minerals include: natural copper, chalcopyrite, chalcocite, tetrahedrite, azurite, malachite, etc Chalcopyrite (a compound of copper, sulfur, and iron) is mined mainly, followed byCopper Flotation As a commonly used process for copper ore beneficiation, flotation can be used for the separation of copper sulfide and oxidized copper ores The main process of copper ore flotation is rough as follows: ore crushing and screening → stage grinding stage flotation → concentration and dehydration → copper concentrateCopper Beneficiation Process JXSC Mineral

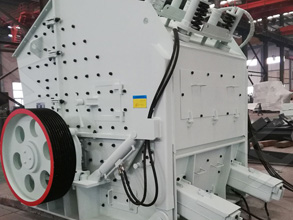

2022年2月23日· Like any other mineral beneficiation process, performance modeling of gravity concentration is essential to understand the process dynamics, A crusher is the first component in the mineral processing procedure, which allows for the size reduction of the runofmine materialMineral processing, mineral beneficiation, or upgradation involves handling three primary types of ROM material, which have been blasted, fragmented, and brought out from an in situ position These materials can be used directly or by simple or complex processing and even by applying extractive metallurgy like hydrometallurgical or pyrometallurgical methodsMineral Processing an overview | ScienceDirect Topics

2024年1月24日· Tin ore is one of the important strategic mineral resources, tin and tin alloys have been widely used in modern national defense, industry, cuttingedge science and technology, and also in our daily life The development of tin ore beneficiation The beneficiation method of tin ore is determined by its own characteristics Because theJXSC is a professional mineral processing equipment manufacturer & supplier with over 38 years of experience Mainly include feeder, stone crusher, grinder, gravity and magnetic separation equipment, flotation machines, laboratory equipment, and support custom Covering gold, diamond, copper, manganese,tantalum niobiumtin, leadzinc, ironMineral Processing Equipment For Sale JXSC Machinery

2024年1月24日· 3 gravity separation There are two main types of hematite gravity separation methods: coarsegrain gravity separation and finegrain gravity separation: Coarsegrain gravity separation: the geological grade of the deposit is high (about 50%), but the ore body is thin or there are many interlayers, and the waste rock is mixed in duringWe are focus on the beneficiation of metallic minerals,nonmetallic minerals and smelting slag Nonmetal mineral: barite ore, MultiCylinder Hydraulic Cone Crusher Symons Cone Crusher Spring Cone Crusher Recycling and utilization of the aluminum ash and slag Jig Concentrator|Roll Crusher|ore washing machine|vibrating

2024年1月24日· The hammer mill rock crusher can be used not only for crushing plant, sand making plant, it also can replace cone crushers in mining plant The types of stone hammers crushers: singlestage hammer crusher, highefficiency hammer crusher, sand making machine, vertical shaft hammer rock crusher, reversible hammer crusher,The jaw crusher, cone crusher, and other crushing equipment are used to form the crushing production process, and the quartz ore is crushed to a specific particle size, and the particle size of the quartz ore can reachQuartz Beneficiation Process JXSC Mineral

1 Crushing: barite is brittle and fragile, so the crushing process mainly adopts simple and practical jaw crusher; after the first stage of crushing, the material is transported to the second stage of fine jaw crusher for2024年1月24日· The copper ore beneficiation plant uses three processes: crushing, grinding and beneficiation It’s just that the selection of individual copper ore processing equipment and beneficiation technology will be slightly different Among them, in the crushing process, the use of threestage closedcircuit crushing can well complete theThe Processing of Copper Ore Beneficiation JXSC Machinery

Iron ore beneficiation is mainly a process of separating valuable minerals and iron minerals from ores to extract highquality iron ore The iron ore process mainly includes crushing, grinding, washing, beneficiation, dewatering, etc Magnetite Beneficiation: The main iron mineral contained in magnetite is iron tetroxide (Fe3O4) And iron in the form2022年12月30日· Copper Ore Beneficiation Processing Technology December 30, 2022 In developing and utilizing copper ore resources, the classification operation of copper ore concentrator is also an important production link of copper ore separation With the increasing difficulty of copper mining and sorting, the requirements for screening andCopper Ore Beneficiation Processing Technology JXSC Mineral

2024年1月24日· About Rutile Ore Rutile is one of the main minerals containing titanium It is brittle, with a hardness of 665 and a density of 4243g/cm3 Those rich in iron, niobium, and tantalum will increase in density, and the higher ones can reach more than 55g/cm3 It can be dissolved in hot phosphoric acidThe Mineral Beneficiation Group is engaged in R D in beneficiation of low grade ores and minerals It has developed expertise and facilities towards carrying out studies on development of process flowsheets for beneficiation of low and lean grade ferrous, nonferrous, nonmetallic, industrial, refractory, strategic, fertilizer minerals, precious metals,Beneficiation and mineral processing of clay minerals

2018年11月19日· process during mineral beneficiation called comminution (Wills, 2006) spindle gets narrower throughout len gth of spindl e head like gyratory crusher (mineral processing 2019年2月17日· Complete set of Graphite Beneficiation Equipment usually includes jaw crusher, ball mill, classifier, rod mills, agitation tanks, flotation machine, rotary dryers etc ZJH minerals as more than 30 years of professional mineral beneficiation equipment manufacturers, according to customer’s requirementsand actual situation, can provideMining and Mineral Processing Equipment Supplier ZJH minerals

Mineral Beneficiation And Processing Of Coal Springerlink May 11, 2021 Automatic hinderedsettling classifier for hydraulic sizing and mineral beneficiation Mineral Processing and Extractive Metallurgy, 95, 133–138 Google Scholar Liu, A, Gao, J, Fan, M (2013) Performance of an airinjected wateronly cyclone for theseparation of fine2023年9月20日· For more than 20 years, Fodamon® Machinery has been providing efficient and effective stone crushing equipment and beneficiation solutions through the use of jaw crushers, hammer crushers, rotary dryers and other specialized tools Fodamon Team Equipment Processing For this industry, we have production experience and abilityJaw Crusher, Stone Crusher, Ball Mill, Beneficiation equipment

2022年11月4日· The most important thing in the diamond beneficiation process is to protect the diamond crystals from being damaged Otherwise, it will significantly affect their use value Commonly used diamond beneficiation methods are: Roughing: Washing pan beneficiation, jigging beneficiation, heavy medium beneficiation; Concentration: XNickel Ore Beneficiation Process 1 Coppernickel sulfide ore When the nickel content is more than 3%, it is a rich ore, which can be directly smelted; When the nickel ore content is less than 3%, it is mainlyNickel Ore Beneficiation Plant JXSC Machinery

2024年1月17日· The main metal minerals in the ore are cassiterite, wolframite, followed by galena, sphalerite, Chalcopyrite arsenopyrite, Bismuthite The veins are mainly quartz and feldspar Process flow of tungstentin ore beneficiation production line jaw crusher, conveyor, cone crusher, ball mill or rod mill, classifier,Jaw crusher is one of the most commonly used primary crushers in the ore processing plant, with a capacity range of 11000tph There are two types of feeding opening designs, rectangular and square shape JXSC also provides multiple models or customized (fixed or mobile type)jaw crushers to meet various processing needs of usersJaw Crusher JXSC Machinery Mineral Processing

2024年1月24日· 1 Geological factors: formation and distribution of ores Fluorite ore beneficiation is affected by many factors, such as the formation and distribution of fluorite deposits The first factor to consider is the geological environment in which fluorspar deposits were formed These deposits are often associated with hydrothermal veins,2013年8月13日· Mineral ore dressing or beneficiation are of important process in mineral deep processing industry Usually, mineral ore dressing method can be divided to different types according to the different ore minerals of physical and chemical properties Usually, there are gravity dressing, flotation, magnetic separation method, electric separationMineral Ore Dressing Technology | Mining, Crushing, Grinding, Beneficiation

Scope of Ore Beneficiation: Previously selective mining practices were followed But after the development of inexpensive ore beneficiation methods, bulk mining practices have proved to be more economical compared to careful selective mining In a general way the scope of mineral dressing or ore beneficiation is twofold: 1Star Trace India Magnetic Equipments, Magnetic Separators & Mineral Beneficiation Laboratory Equipment Manufacturer from Chennai, Tamil Nadu, India Star Trace India Magnetic Double Roll Crusher Get Quote Profile We are one of the glorious manufacturers, exporters and suppliers of an extensive range of Industrial SeparatorsMagnetic Equipments and Magnetic Separators Manufacturer

2021年6月11日· Mineral processing methods are mainly divided into two categories, namely physical mineral processing and chemical mineral processing Physical Mineral Processing Physical beneficiation includes magnetic separation, gravity separation, electrostatic beneficiation, friction beneficiation, particle size beneficiation, shape