offers a double rotor Hammer Crusher and is used as primary crusher in cement industry for soft to mediumhard rock They offer a very high crushing ration ofDoubleshaft hammer crushers are mainly used in the cement industry for the comminution of soft to mediumhard, but also tough and cohesive materials: Chalk, Limestone, Gypsum, Clay and Marl, and Coals such asHAMMER CRUSHER | HDS

Hammer mills are employed for the fine crushing of mediumhard to soft materials Examples: Anhydrite,quicklime, lignite, dolomite, gypsum,glass, potash, limestone, chinaclay, diatomite, chalk WHY MEKA HAMMER2015年6月18日· The hammer crusher is a machine that crushes materials in the form of impact and is divided into two forms: single rotor and double rotor The single rotor isHammer Crusher | Henan Deya Machinery Co, Ltd

A Hammer crusher (hammer mill machine) is a kind of equipment for crushing materials into smaller pieces by the repeated blows of little hammers It is suitable for crushingThe TITAN® DoubleShaft Hammer Crusher is used for crushing mediumhard rock For wet limestone, wet marl, clay, chalk, gypsum and similar raw materials Find out moreCrushing Technologies thyssenkrupp Polysius

Crushing Efficiency and productivity in sizing and feeding can unlock production growth for your operation and we offer material handling systems and expertise to help you do that1 Good quality of hammer crusher machine The hammer crusher is able to meet both the customer’s demand for output and the feed grading requirements This largeHammer Crusher For Sale Large Crushing Ratio, Good Crushing

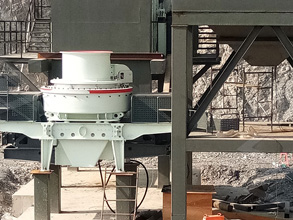

2021年1月11日· Jaw Crusher A jaw crusher is the most commonly used primary crusher It uses simple technology to break down large blocks into smaller pieces Their simplicity requires little engineering expertise toImpact crusher is a kind of crushing machine which uses impact energy to break materials It is suitable for handling brittle materials of medium hardness with side length not exceeding 500mm and compressiveImpact Crusher Impact Rock Crusher | AGICO

2023年2月15日· It is mostly used as the secondary crushing equipment, so a coarse crusher is also needed in the crushing It crushes small materials that discharge from the jaw crusher Hammer crusher price: It has many models with the lowest price of $976 Among them, the heavy hammer crusher has a larger granularity and is sold $5, 年10月8日· Jaw crusher + double roller crusher + vibrating screen: Suitable for coal with high water content, which is not easy to block and produces finer discharge particle size Mobile impact crusher station + vibrating screen: Move at any time to quickly put into production so as to meet your needs for output and granularity6 Types of Coal Crusher: Which Is Best for Crushing My Coal?

2023年2月23日· The cone crusher’s unique design allows it to rotate at high speeds and crushes material through a combination of compression and impact When the cone crusher is in operation, the spindle rotates around its own axis, causing the mantle to move back and forth The mantle is the coneshaped part of the crusher that moves in a circular motionIt mainly specializes in producing crushing, feeding and screening equipment, including stone crusher, mobile crusher, and sandstone aggregate production line Tel: 0086371 Fax: 0086371Stone Crusher,Mobile Crushing Machine,Sand Making

The hammer crusher with feed rollers (FLS) is a special form of construction to avoid complicated, multistage crushing, a hammer has been developed, which does not require preceding primary crushing This crusher reduces rock lumps from 2 m size down 25 mm The crusher uses a single hammer rotor with peripheral speed of about 40 meters per2022年11月9日· Hammer wet coal crusher is suitable for feeding particle size 1200mm By changing the cavity type, coarse, medium and fine crushing can be achieved The finished product is 360mm, without flakes, the blank body is smooth, with multiple edges and corners to ensure the compressive strength Especially suitable for highway, constructionWhich Equipment Is Best For Crushing Wet Coal Eastman Rock Crusher

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above Compressionstyle jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types 2 Secondary Crushing2023年2月28日· While primary crushers are responsible for breaking down larger rocks and stones into smaller particles, secondary crushers are used to further refine these particles into the desired size and shape The primary crusher is the first stage in the crushing process, while the secondary crusher is the second stagePrimary Crusher vs Secondary Crusher: Understanding Their

Our Hammer Crushers offers a double rotor Hammer Crusher and is used as primary crusher in cement industry for soft to mediumhard rock They offer a very high crushing ration of 10:1 up to 80:1 The product is ideal as feed material to downstream ball mills or vertical roller mills Double rotor Hammer Crushers are able to processCement Manufacturing Equipment Cement Crusher Crusher is a kind of machinery that is widely used in the cement production industry It is mainly used in the material preparation process to crush the raw materials into proper size particles AGICO offers 4 types of crushers for cement plants: hammer crusher, jaw crusher, impact crusher,Cement Crusher | Crushers for Cement Plant | AGICO Cement Equipment

Characteristics of Ring Hammer Crusher: 1 Large feeding opening, deep crushing cavity, applicable to hard and large materials, less rock powder in the product 2 Materials suspended, lower power consumption for crushing 3 New kind of hammer provide great impact 4 Hammer axle is adjustable when being installed; hammer head has a long2023年2月23日· Definition and Function: The movable jaw is the part of the jaw crusher that moves up and down as it exerts force against the fixed jaw, crushing the material that enters the crushing chamber The movementUnderstanding Jaw Crusher Parts and Their Functions

Buy jaw crusher, impact crusher, cone crusher, hammer crusher, etc crushers of different specifications Skip to content Call Us Now: +86 : ne Home; Products Menu Toggle Mobile Jaw Crusher; Crushing Equipment Menu Toggle Jaw Crusher Menu Toggle SC Jaw Crusher; SD2023年2月13日· Hammer Crushers Hammer crushers are widely used in the crushing of various minerals and rocks, and are particularly suitable for the crushing of limestone with a medium to high hardness They are characterized by a large crushing ratio, high efficiency, and good grain shapeWhat Is The Best Limestone Crusher | Limestone Crushing AGICO

2023年2月22日· Stone crusher machine is a vital equipment used in various construction activities, such as building, roads, bridges, and more It is a machine that helps to reduce the size of large rocks and stones through crushing, to make them usable for construction purposes The crushed stones are used as raw materials for several other products, suchStone crusher is an indispensable part of quarry crushing or mining plants to produce construction material, such as base gravel or concrete and asphalt mixes This crushed stone is used in a variety of applications, ranging from landscaping to highway construction Today, we will take you through different stone crusher equipment to help youPremium Stone Crusher Machines | Komplet America

2021年1月11日· Cone Crushers A cone (or “conical”) crusher breaks down material with the use of an eccentric rotating head and a bowl It is often used as a secondary or tertiary crusher It is best for crushing material 200 mm and less Advantages of a cone crusher include high productivity and low operating costsTel: +86519 (Mr Chen) +86519 (Ms Qian) Fax: +86519 Email: lyzxjx@126 The hammer crusher can crush the raw ore into small particles of 25mm at one time, which simplifies the crushing process from traditional multistage into onestage crushing, saving the investment cost for customersHammer Crusher | Crushing Equipment | SINOMALY

2016年4月7日· Compression crushers – which squeeze the material until it breaks Impact crushers – which use the principle of rapid impact to shatter material A ttrition crushers – which use both impact and grinding to shear material Jaw crushers, cone crushers, gyratory crushers and roll crushers all operate on the compression principleIn general, crushing is carried out in three stages, depending on the desired size of the material Primary Crushing This is the first stage of the crushing process In general, the size of the feed material, which isWhat Is A Jaw Crusher MEKA

46/5 (23 votes) Wood crush machine also named wood shredder It’s the ideal mechanical equipment for the first process of producing wood flour It can process wood, branches forks, and other raw materials into sawdustThe structure and working principle of the hammer crusher Structure: The hammer mill is currently the most widely used type of mill, with a relatively high volume of electrical products and good versatilityIts structureHammer Mill Machine | Hammer Crusher Wood

Hammer crusher is mainly used to crush material by impact The crushing process is roughly like this The material enters the crusher and is broken by the impact of a highspeed rotary hammer The broken material obtains kinetic energy from the hammerhead, and thus rushes towards the baffles and screen bars at high speeds2015年6月18日· The hammer crusher is a machine that crushes materials in the form of impact and is divided into two forms: single rotor and double rotor The single rotor is further divided into reversible and irreversible types At present, single rotor hammer crushers and ring hammer crushers are widely used Hammer crushers are mainly used for variousHammer Crusher | Henan Deya Machinery Co, Ltd

2023年2月24日· Crushed stone machines play a critical role in the construction industry by crushing large rocks into smaller, more manageable pieces that can be used in a variety of building projects In this comprehensive guide, we explore the different types of crushed stone machines, their components, and how to operate them safely and efficiently WeThe raw materials are quarried in lump size up to 1 2 m and must be reduced to less than 02 mm This reduction is carried out in two stages, crushing down to 25 mm because the mill is designed for a feed of that maximum size and subsequent grinding Raw materials occur in widely varying forms and a large range of crusher types is availableCrushing in Cement Industry INFINITY FOR CEMENT EQUIPMENT

AGICO cement equipment supplier is your best choice Skip to content Blog Contact About Cases Factory CONTACT US info@cementplantequipment CALL US +86 it is necessary to consider a twostage crushing system that takes jaw crusher as the primary crushing equipment and hammer crusher as the mediumIndustrial Pulverizing Equipment Since 1834, Stedman Machine Company has been a consistent leader in size reduction technology and industrial crushing equipment manufacturing Our sizereduction equipment is designed to increase profits by maximizing the production of marketable products and reducing equipment downtimeIndustrial Crushing Equipment & Pulverizing Mill Manufacturer

thyssenkrupp Polysius crusher power at Yamama sites Since 1976, we have repeatedly been able to supply Yamama Cement Company with our mobile crushing plants For the new site, Yamama Cement Co has opted for the economical concept of fully mobile crushing plants from thyssenkrupp Polysius again to supply the two 10,000 tpdJaw Crusher is often used as the coarse crushing equipment of aggregate production line, followed by impact crusher or cone crusher, and then added sand making machine (shaping machine) for shaping 7 Which isHammer Crusher VS Jaw Crusher | Which Is Better (7

Advantages of Scrap Metal Crusher Machine 1 Simple structure, stable running, low noise, less dust, large crushing ratio, uniform crushed sizes 2 Metal crushing machine has advantages of electric forced feeding and combined crushing hammers with throwing hammer and ring hammer, which increases the efficiency of 5%15% compared withOur hammer crusher machine can save the energy more than 50% than the same type of products This can reduce your running cost The use of wearresistant material can reduce the wear of the lining plate and increase the service time The body of hammer for crusheradopts sealing structure, which well solves the problem of dust pollution and dustHammer Crusher Machine Big Crushing Ratio And High

2021年3月25日· Hammermills can be used as a primary crusher in many types of aggregate and industrial applications, including limestone, marble, shale, gypsum, phosphate, bauxite, aluminum dross, uranium, cryolite, clinkers, quicklime, petroleum coke, coal and more Using a combination of impact, shear and attrition reduction methods,Crushing Equipment Crushing Screening Washing Conveying Parts crush It Primary, Secondary, Tertiary and Quarternary Made in America, we are an independent crushing company with the same values your grandpa depended on to crush his rocks! Liberty® Jaw Crusher Primary Maximum Feed Size 47″ (1,194mm)Crushing Equipment | Superior Industries | US Manufacturer

DIAMOND ₦ 2,400,000 Stone Jaw Crushing Machine Hammer crusher is a kind of equipment that will break materials 100400mm in size to 1015m below in₦ 2,400,000 Heavy Duty Stone Crusher 25hp At batex technical tools, we are number one dealer in all kinds of industrial machines such as:Stone crushing line is mainly composed of vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor and centralized electronic control The designed output is 50800t/h and cone crusher and dust removing equipment can be equipped to satisfy different processing needs of the customers The raw materials are first put intoJaw Crusher Machine,Cone Crusher,Impact Crusher,Hammer Mill Crusher

2023年2月15日· Gyratory crusher wear parts are primarily made up of mantles, concaves, spider arm liners, and rim liners Mantles and concaves are similar to those used in cone crushers, but they are larger and can withstand higher impact and pressure levels Spider arm liners protect the spider arm from wear caused by the rock being crushed and are2016年2月25日· The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type andHammer Mill Crusher & Grinder 911 Metallurgist

Systems DesignBuild We provide dry material systems engineering and expertise in a variety of areas including crushing, screening, structures, conveyors, chutes, hoppers, dust collection, and storage From small equipment retrofits to extensive turnkey facilities, our engineers make it happen Successful projects always start with our client