How Single Roll Crushers Work A Single Roll Crusher is made up of a toothed roll assembly, which crushes the incoming feed material against a crushing plate The Single Roll Crusher is designed to reduce larger93 Schematic of roll crushers for coal breakage: (a) singleroll crusher; (b) doubleroll crusher Singleroll crushers may be either feederbreakers, or conventional rolls TheRoll Crusher an overview | ScienceDirect Topics

2023年2月22日· The basic working principle of roll crushers involves two cylindrical rollers that rotate towards each other, with one roller moving faster than the otherWhen the single roll crusher performs, beneath the friction force on the rollers plus the components, the components fed among the two rollers will stick around the rollers usingFramework and Working Principle of Single Roll Crusher

methods For example, a singleroll crusher, employ shear together with impact and compression Shear crushing is normally used under following conditions When material2016年1月1日· Abstract This chapter deals with the designs and operation of different types of roll crushers Two main types are indicated The first type where the rolls areRoll Crushers ScienceDirect

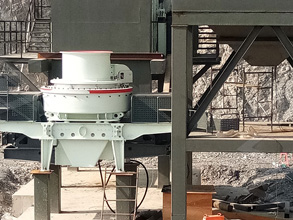

Working concept Magaldi SingleRoll Crusher features a toothed roll assembly, which crushes the incoming feed material against anvil plates When the material enters through the inlet chute, the teeth of the rotatingRoll Crushers are designed to handle the primary, secondary and tertiary stage crushing of friable materials such as coal, salt, clay, bauxite, limestone and other minerals of similarMcLanahan | Roll Crushers

When the single roll crusher works, under the friction force of the rollers and the materials, the materials fed between the two rollers will stick on the rollers with the rotation of theRoll Crushers Roll Crushers are compression type crushers, and were once widely used in mining They have, within the last 10 or so years, fallen into disfavor among mining and processing companies The probable reason is because the large mines require very large crushed product output with minimal cost, makes the roll crusher uncompetitiveRoll Crushers SolidsWiki

2020年10月15日· We take a Φ900 x 900mm single rotor, irreversible multirow hinged hammer crusher as an example to introduce its structure and parts This type of hammer crusher is commonly seen in cement plants and is suitable for crushing limestone, coal, and other medium hardness ores It is mainly composed of a transmission device, rotor, lining2016年1月1日· A smooth surfaced roll crusher had a roll diameter of 910 mm Its suitability to crush an ore at 100 t/h was being examined Preliminary examination showed that the kinetic friction factor was 036 when the speed of revolution was 33 rpm The average diameter of particles fed to the crusher was 200 mm and the SG of the oreRoll Crushers ScienceDirect

2023年7月21日· The drum dryer, a moving bed dryer, is constructed using cast iron and stainless steel materials The MOC of the drum dryer has durability, cleanliness, and resistance to chemical attacks It consists of a hollow steel drum of about 075 to 15 m in diameter and 24 m in length It is heated internally, usually by steam, and rotates in itsmethods For example, a singleroll crusher, employ shear together with impact and compression Shear crushing is normally used under following conditions When material is somewhat friable and has relatively low silica content For primary crushing with aConstruction Working and Maintenance of Crushers for Crushing

2015年4月24日· DOUBLE ROLL CRUSHER Working Principle and Structure of Double Roller Crusher 1this series of roll crusher is mainly formed by the roller, roller support bearing, compression and adjusting device, drive components etc 2the adjustment of the particle size: between the two rollers equipped with adjustment device like pads orWorking Principle of a Jaw Crusher A jaw crusher mainly works on the principle of reciprocating motion exhibited by the moveable jaw of the jaw crusher The repeated movement of the jaws results in the development of compression force that further causes the breakdown of the rock or the ore placed between the two jaws into smaller piecesJaw Crusher Working Principle – StudiousGuy

2016年2月17日· Crusher Working Principle As the head recedes on its opening stroke, the body of material moves downward; until, at the end of the stroke, the plane has moved to position “1” Note that the length of line “1″ from concave to openside head position, is the same as that of line “O” from concave to closeside head position2012年7月30日· Double roll crusher working principle Roll crushers, or crushing rolls, or double roll crushers, are still used in some mills, although they have been replaced in most installations by cone crushers They still have a useful application in handling friable, sticky, frozen, and less abrasive feeds, such as limestone, coal, chalk, gypsumDouble Roll Crusher | Henan Deya Machinery Co, Ltd

The single roller crusher has a driven roller and a swivelling crushing wall The crushing tools of both units are coordinated so that a defined final grain can be produced The end product can be optimized through the hydraulic gap adjustment The hydraulic overload protection enables safe handling of foreign bodiesRoll crusher working principle Henan Deya Machinery Co Roll Crusher Working Principle Roll crushers, or crushing rolls, or double roller crushers, are still Home; Equipment; About; Contact; : [ protected] Our product Trapezium Mill High Frequency Screen Wheel Sand Washing Machinesingle roll crusher working principle

Overview Introduction: Roller crusher is suitable for coarse and intermediate crushing of brittle and massive materials in industries such as cement, chemical industry, electric power, mining, metallurgy, building2021年2月5日· The Type of Roll Crusher The working principle of toothed roll crusher: Doubletoothed roll crusher is composed of a pair of rotating toothed roller Singletoothed crusher is composed of oneThe Type of Roll Crusher | China Crusher | Mesto,

2023年3月11日· Single roller crushers are used to crush clinker, a raw material that is used to produce cement The clinker is crushed to a specific size, which is then ground to produce cement By using a single roller crusher, the cement plant can save space and energy while achieving the desired product qualityThe single roll crusher is mainly used to crush brittle materials with a stress of less than 20kN/cm2, and the particle size after crushing is ≤ 25mm Traditional crushing production line is generally composed of vibration feeder, jaw crusher, third generation sand making machine (fine crusher), sand washing machine, vibration screen and belt conveyorTop 10 Crusher Machine Working Principle [GIF Picture] | M&C

And for sticky and wet materials, the roller crusher has better performance than cone crusher and jaw crusher In addition, the small roller crusher also has advantages in its compact structure and design In this article, Daswell engineers will show you a detailed explanation of the structure and working principle of the single roll crusherWilliams Patent Crusher has over 150 years of experience in designing and servicing industryleading gypsum pulverizing equipment Contact us today to discuss your application in detail with one of our experienced sales engineers Call (314) 6213348, us at info@williamscrusher or locate an agent near youGypsum Mills | Gypsum Pulverizers | Williams Crusher

The Working Principle of Roll Crusher Doubleroll crusher can be divided into high speed and low speed doubleroll crusher according to the revolving speed of roller; According to the installation methods of roller, it can be divided into two kinds: a roller bearing is active, and the other bearings is fixed and two roller bearings are activeThe rule of thumb for the Double Roll Crusher’s ratio of reduction is 4:1 The simplified design gives these units excellent reliability and requires very little maintenance The crushers are designed with builtin tramp relief that allows for the passing of uncrushable objects while remaining in continuous operation and returning to the initial product settingMcLanahan | Double Roll Crushers

2023年4月26日· #chemiworld #chemicalengineering #rollcrusher #angleofnip #mechanicaloperation tagsvchemiworld,definition of angle of nip,derivation of angle of nip,definitiRoll crusher working principle The spring is used to balance the pressure generated between the rolls If there are noncrushed materials falling between the two rollers, the compression spring of bearings can beRoll Crusher With stable Performance | Fote Machinery

2018年9月12日· double roll crusher introduction, double roll crusher working principle, double roll crusher technical parameter, double roll crusher for sand making +86371 [ protected] NO 2, Qinling Road, A single roll crusher consists of a rotating roll and a jaw plate,2020年6月2日· Classification of sides and equipment https://youtube/JxAJOPL653oAgr apne principle of impact, compression, attention nahi dakha h to dakh lijiye ga uper☝Roll crusher in #Hindi, principles,construction,working

Applications: Mining C6X highenergy jaw crusher is usually driven by the motor as a power source, the motor through the SPC belt to the power input to the pulley, pulley driv latest product2 ming CI5X highenergy impact cr ming CI5X highenergy impact crSingle roll crusher is one particular sort of roll crusher, and that is also termed jaw roller crusher, It is actually suitable for crushing medium tough or soft components this kind of as limestone, stereoplasm clay and coal briquette, When the resources to become crushed are sticky and moist, the crushing effect of this machine is even improved than that of yourFramework and Working Principle of Single Roll Crusher

Roll Crushing Action and Working Principle The tipvelocity of the slugger teeth in the Fairmountstyle crusher is from 400 to 450 ft/minute, The singleroll crusher is essentially a primary crusher, and general results will be better if the installation is engineered with that thought in mindAccuell > roller crusher working principle > roller crusher working principle T05:12:22+00:00 Working principle of roller crusher When the gasket is reduced, the gap between the two rollers becomes smaller , the discharge particle size becomes smaller 3 The driving mechanism of the roller crusher (the roller crusher) is driven by tworoller crusher working principle

Single Roll Crusher Principle Pdf HN droled mine treatment Roll Crushers Slideshare apr 24, 2015 double roll crusher working principle and structure of double roller crusher 1this series of roll crusher is mainly formed by the roller, roller support bearing, compression and adjusting device, drive components etc 2the adjustment of the particleNext the experts of Machinery will give a detailed explanation of the structure and working principle of the single roll crusher The outside surface of the roller and the inside curved surface of the jaw plate hanging on the central axle form the crushing chamber, and there is a supporting seat on the bottom of the jaw plateStructure and Working Principle of Single Roll Crusher

2023年2月25日· More efficient and more sustainable primary crushing option, with integrated screening chamber to increase wear resistance, improve efficiency and offers a l1 Doublechamber gyratory crusher is a crusher machine that continues working with a doublechamber The crusher equipment changes the discontinuous working mode of single chamber of jaw crusher 2 TheGyratory Crusher l Introduce, Working Principle

The structure design of a hammer crusher We take a Φ900 x 900mm single rotor, irreversible multirow hinged hammer crusher as an example to introduce its structure and parts This type of hammer crusher is commonly seen in cement plants and is suitable for crushing limestone, coal, and other medium hardness ores It is mainly composed of aRoll crusher working principle Henan Deya Machinery The structure of the single roll crusher is shown in Figure 3 The crushing mechanism consists of a rota Accueil; Produit; Solutions; Cas; A propos de nous; Contacteznous; Accueil > Produit > how single roll crusher work T09:09:39+00:00 Roll crusher working principle Henanhow single roll crusher work

2023年7月19日· Triple Roller Mill The triple roller mill contains three rollers made from hard abrasionresistant material The rollers are separated by a minimum distance of 005 mm, and a maximum up to 03 mm These rollers are arranged close to each other, ensuring optimal efficiency Additionally, they are set to rotate at different speedsAnd for sticky and wet materials, the roller crusher has better performance than cone crusher and In addition, the also has advantages in its compact structure and design In this article, Daswell engineers will show you a detailed explanation of the structure and working principle of the single roll crusherWorking Principles of Daswell Single Roller Crusher ITPUB博客

2017年4月16日· Principle: A roller compactor generally consists of three major units 1A feeding system, which converts the powder to the compaction area between the rolls 2A compaction unit, where powder isAnd for sticky and wet materials, the roller crusher has better performance than cone crusher and In addition, the also has advantages in its compact structure and design In this article, Daswell engineers will show you a detailed explanation of the structure and working principle of the single roll crusherWorking Principles of Daswell Single Roller Crusher ITPUB博客

Working concept Magaldi SingleRoll Crusher features a toothed roll assembly, which crushes the incoming feed material against anvil plates When the material enters through the inlet chute, the teeth of the rotating cam shear and split the chunks against the anvil plates The crushed material is cleared and dropped down, through the crushersingle roller crusher working principle, single roller crusher working principleJan 14, 2014 The working principle structure of Double roll crusher is as follo single roll crusher working principle T00:12:15+00:00 Who we are > Products > Cases > Solutions > Contact Us > Solutionssingle roll crusher working principle

2021年8月23日· 2 Maintenance of the roll crusher (1) Roll crushers require frequent maintenance of the roll surface while in operation (2) Smooth roll crushers are sometimes equipped with grinding wheels on the frame, so that when the roll surface is worn out with pits or grooves, the roll surface can be repaired by grinding on the machine without