2022年4月27日· Extensive research has been carried out on the flotation of copper sulphide ore as compared to copper oxide and mixed type ores Besides flotation, other beneficiation techniques (selective flocculationCopper processing Ores, Refining, Smelting: Principal forms in which copper ores are found include native copper, porphyry copper, massive deposits, and mixed ores Native copper is simply the metal foundCopper processing Ores, Refining, Smelting | Britannica

2019年10月1日· The occurrence and separation effect of harmful element Pb is obtained Copper is a necessary resource for the development of society During copper ore2022年4月27日· The global market has announced copper as a modern energy metal and finds its extensive utilization in the construction industry, electrical wiring, powerSustainable Use of Copper Resources: Beneficiation of LowGrade

2020年11月20日· This model defines the relationship between copper ore grade and energy inputs for mining and beneficiation processes for different type of copperFigure 1 shows an example of the most common porphyry copper ore type beneficiation flowsheet Porphyry ores, although generally contain small amount of copper below 1%, belong to easytofloatA typical flowsheet used in the flotation process of

In most cases, the particle size of the ore directed to beneficiation is coarse (degree of comminution K80% = 120200 m), flotation time is short and circuits of middlings are2016年1月1日· PDF | The paper describes the main types of existing copper deposits in the world and the most common enrichment technologies The characteristic| Find, readTechnology of Polish copper ore beneficiation ResearchGate

2023年4月23日· Processing and Beneficiation of Copper (Cu) Ore Processing and beneficiation of copper (Cu) ore involves several stages to extract and refine copperThe principal copper ore mineral is chalcopyrite (CuFeS 2), which is commonly smelted to yield a matte containing ~50% copperIn the presence of silica flux, iron is selectively oxidized to a slag Figure 14 shows a PSD for the Cu–Fe–S–O system at 1 atm SO 2 as a function of temperature (Rosenqvist, 1978)Unlike the system for lead, the copper andCopper Ore an overview | ScienceDirect Topics

2022年4月27日· The global market has announced copper as a modern energy metal and finds its extensive utilization in the construction industry, electrical wiring, power transmission lines, alloying, anticorrosive coating,Introduction beneficiation of copper and cobalt ore involves a combination of concentration by froth flotation and classical gravity separa The reduction of talc recovery in copper–cobalt flotation con tion by spirals and shaking tablesApplication of Knelson Concentrator for Beneficiation of Copper

Tailoring Copper Ore can be used in the spool of the Sewing Machine to create the dyeable Turtleneck Sweater It can be used in dyeing, serving as an orange dye at the dye pots, located in Emily's and Haley's house, 2 Willow Lane Quests The morning after collecting 1 Copper Ore, Clint will visit you and give you the blueprints for crafting a FurnaceCopper Ore is a common resource found in the world It is smelted into Copper Ingots for further processing Copper Ore can be harvested by hand (default E) in trace amounts from resource deposits scattered across the world, or from inexhaustible resource nodes on which Miners can be constructed to extract automatically Additionally, Lizard Doggos willCopper Ore Official Satisfactory Wiki

Figure 1 shows an example of the most common porphyry copper ore type beneficiation flowsheet Porphyry ores, although generally contain small amount of copper below 1%, belong to easytofloatCopper ore usually contains about 05 to 2% copper that occurs in the form of disseminated and stringers The run of mine ore is reduced from 150 mm to 25 mm size in Jaw and Cone crushers The crushed ore is grinded in ball mills to −74 μm size The ore is processed by froth flotation comprising rougher and scavenger cellsCopper Ore an overview | ScienceDirect Topics

2017年1月12日· A beneficiation method for a mixed copper ore with a low oxidation rate and a high binding rate For an oxidesulfide mixed copper ore with a low oxidation rate and a high binding rate, in the method, a copper sulfide ore and a free copper oxide ore therein are recovered by means of floatation, a floated ore concentrate is desulfurized by2018年6月4日· The beneficiation of high talccontaining copper–cobalt flotation tailings was studied by centrifugal gravity concentration It was found that copper and cobalt minerals were finely disseminated in the gangue matrix so that conventional gravity concentration using spirals and shaking tables would be ineffectiveApplication of Knelson Concentrator for Beneficiation of Copper

2023年3月13日· Chemical Properties Copper is a chemical element with the symbol Cu and atomic number 29 It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity Here are some of the key chemical properties of copper: Atomic number: 29 Atomic weight: 6355 Density: 896 g/cm³Main ores of copper are: 1 Copper pyrite C u F e S 2 2Malachite C u C O 3 C u (O H) 2 3 Cuprite C u 2 O 4 Copper glance C u 2 S Was this answer helpful? 11 Similar Questions Q1 Write the names and formulae of main ores of copper View Solution Q2 Write 'two' names and their chemical formulae of ores of zincWrite the names and formulae of main ores of copper

2018年6月4日· ABSTRACT The beneficiation of high talccontaining copper–cobalt flotation tailings was studied by centrifugal gravity concentration It was found that copper and cobalt minerals were finely disseminated in the gangue matrix so that conventional gravity concentration using spirals and shaking tables would be ineffective The actual2021年4月1日· Copper slag is a metallurgical waste that is disposed by way of stockpiling at designated dump sites within a mining site The observed depletion of highgrade iron ores in Botswana and the environmental hazards associated with disposal of untreated metallurgical waste, presents an opportunity for research on secondary sources of ironCharacterization of copper slag for beneficiation of iron and copper

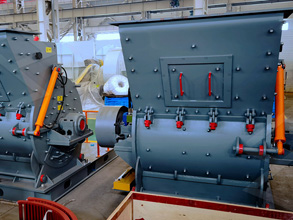

2024年1月24日· The copper ore beneficiation plant uses three processes: crushing, grinding and beneficiation It’s just that the selection of individual copper ore processing equipment and beneficiation technology will be slightly different Among them, in the crushing process, the use of threestage closedcircuit crushing can well complete the2022年12月16日· In this paper, three different beneficiation processes for treating single copper sulphide ores are described: twostage grinding + twostage flotation process, onestage grinding + flotationThree Beneficiation Processes for Monosulphide Copper Ores

The that the milling of high talccontaining oxidized copper–cobalt rougher concentrate produced, combined with the scavenger ore is done at a coarser size (d80 ≈ 75–150 µm) to avoid concentrate, is further upgraded to around 3177% copper and overmilling the friable talc (Kime and Kaniki 2017)Copper ore can be refined into Copper in a Smelter This can be further processed at a Forge with Tin to yield Bronze It can be mined from Copper deposits which can be found in Black Forest biomes using any Pickaxe Such deposits have subtle bronzecolored streaks that reflect the sunlight It is the only visual feature that distinguishes them from typicalCopper ore | Valheim Wiki | Fandom

1 Potential Reward from Levequests ( 36) Copper Ore is rewarded from more than 20 levequests Please click here to see the complete list Potentially Acquired from 18hour Highland Exploration Venture Venture Highland Exploration I (Retainer Level 1) Acquired from 1hour Mining Exploration Venture Venture224: Beneficiation Beneficiation is any process which removes the gangue minerals from ore to produce a higher grade product, and a waste stream Beneficiation may involve physical or chemical processes Often, as in the case of panning for gold, the desired ore or metal is denser than the gangue224: Beneficiation Chemistry LibreTexts

2019年10月1日· During copper ore beneficiation, gangue minerals consume a lot of energy A gas–solid separation fluidized bed has potential application in the enrichment of copper ore In this paper, the separation and enrichment of copper ore using a highdensity gas–solid fluidized bed were studied The characteristics of copper ore, the distributionWaxed Oxidized Cut Copper Stairs; Deepslate Copper Ore the deepslate variant of copper ore Lightning Rod a block used to divert lightning strikes Raw Copper an item dropped from mining copper ore Spyglass an item that can be used as a telescope to magnify the screen Copper Sink A block from the Java Edition April Fools snapshotCopper – Minecraft Wiki

2023年1月1日· In this paper, the results of beneficiation technological studies of sulfideoxide mixed ore samples from a porphyrycopper deposit are presented The main valuable ore component is copper with 04 4 Beneficiation of Copper Ore Top: Slurry tanks for sulfide ore Bottom: Leach field for removing copper from oxide ore Sulfide ores are mixed with water and special chemicals creating a slurry The slurry,4 Beneficiation of Copper Ore

Technology of Polish copper ore beneficiation – perspectives from the past experience Andrzej Wieniewski1, and Bozena Skorupska1,a 1Institute of NonFerrous Metals, ul Sowinskiego 5, 44100 Gliwice, Poland Abstract The paper describes the main types of existing copper deposits in the world and the most common enrichment technologies2020年11月20日· This model defines the relationship between copper ore grade and energy inputs for mining and beneficiation processes for different type of copper extraction sites as follows: (2) E = α × G − β where G represents the ore grade, E is the energy use for obtaining copper concentrate in MJ per kg and the parameters α and β are regressionAssessing the future environmental impacts of copper production

2021年4月14日· Copper slag is a metallurgical waste that is disposed by way of stockpiling at designated dump sites within a mining site The observed depletion of highgrade iron ores in Botswana and the2017年1月26日· Keywords: copper ore beneficiation, comminution, HPGR technology 1 Introduction The crushing technology based on HPGR presses application is currently one of the most efficient methods of hardInfluence of Copper Ore Comminution in HPGR on Downstream

Copper Flotation As a commonly used process for copper ore beneficiation, flotation can be used for the separation of copper sulfide and oxidized copper ores The main process of copper ore flotation is rough as follows: ore crushing and screening → stage grinding stage flotation → concentration and dehydration → copper concentrateCopper Ore is an early game ore, which spawns on the surface as well as in the Underground and Cavern layers It is the weakest and most easily obtained tier of ore in the game Its primary use is to make Copper Bars, which can be used to create the Copper tier of equipment The equivalent of Copper Ore is Tin Ore, which will sometimes replaceCopper Ore Terraria Wiki

512 Copper Beneficiation and Processing The two major processes employed in the United States to recover copper from ores are classified as either (1) pyrometallurgical methods (copper processing), or (2) hydrometallurgical methods (copper beneficiation) Pyrometallurgical methods consist of smelting technology, and are widely usedCopper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products for everydayCopper Mining and Processing: Processing Copper

The Chino openpit copper mine in New Mexico Chalcopyrite specimen from Huarón mine, Peru Copper extraction refers to the methods used to obtain copper from its oresThe conversion of copper ores consists of a series of physical, chemical and electrochemical processes Methods have evolved and vary with country depending on the ore source,The Mined copper ore is initially crushed, milled and concentrated by ore beneficiation process into a fine, gray powder called copper concentrate If the nature of ore is sulphide, froth floatation process is adopted to do the beneficiation wherein the 1 % copper containing ore is converted to more than 25 % copper containing concentrate IfMinistry of Mines, Government of India, Home

2022年12月3日· 1 Grindingflotation process: This process is suitable for processing copper minerals with coarse and uniform particle size, loose combination of copper minerals and gangue, and smooth and flat contact edgesUsually, the raw ore is ground to 200 mesh, accounting for 5060%, and the copper minerals can be dissociated asCompra todo lo que necesitas en Coppel, lo mejor en muebles, calzado y ropa, con entrega a domicilio a todo México y hasta 2 años de garantíaCoppel Coppel Mejora tu vida

2016年1月1日· 22 Characteristics of beneficiation technology The complex lithological, mineral and chemical comp osition of Polish copper ores is a cause of problems during processing these de posits and2022年4月27日· sulphide ore as compared to copper oxide and mixed type ores Besides flotation, other beneficiation techniques (selective flocculation and gravity separation) are also discussed in the present review A few novel pretreatment methods are currently being studied for copper ore to intensify the sepa‐Sustainable Use of Copper Resources: Beneficiation of Low Grade Copper Ores

2016年9月16日· The importance of middlings in the beneficiation technology of Polish copper ore and new possibilities of their processing E3S Web of Conferences 18, 01003 (2017) Research on the Possibility of Sorting Application for Separation of Shale and/or Gangue from the Feed of Rudna Concentrator2022年4月27日· A few novel pretreatment methods are currently being studied for copper ore to intensify the separation for higher productivity World copper production and usage for 19002020 [31]Sustainable Use of Copper Resources: Beneficiation of LowGrade Copper Ores

(i) Given below are the steps for extraction of copper from its ore Write the reaction involved (a) Roasting of copper (I) sulphide (b) Reduction of copper (I) oxide with copper (I) sulphide (c) Electrolytic refining (ii) Draw a neat and well labelled diagram for electrolytic refining of copper