2013年3月1日· The properties of zirconia powder prepared by alcoholaqueous method after ballmilling had been researched by BET,XRD,TEM and laser granularity instrumentThe results show that by using1994年7月18日· The phase transformation process of zirconia–8 mol % yttria powder mixtures during a high energy ball milling process has been studied by means of x‐rayMechanical alloying process of the zirconia–8 mol % yttria ceramic

zirconia balls have following advantages in solid state synthesis in ball milling High crushing strength and fracture durability, superior wear resistance which has no any2013年12月1日· 10 g of alumina powder (average diameter of 60 μm) was ball milled in aqueous medium (70 ml of distilled water) by 500 g of zirconia balls with varyingEffect of ball size and powder loading on the milling

Abstract Ball milling is a simple, fast, costeffective green technology with enormous potential One of the most interesting applications of this technology in the field of cellulose is the preparation and the chemical2023年5月15日· Wheat gluten and olive pomace powder: Planetary Ballmill: Vessel capacity250 ml Ball Dia10 mm Ball material Zirconia Powder to ball ratio1:10 MillingBallmilling: A sustainable and green approach for starch

As can be seen from the figure, ball mill greater impact on the specific surface area of powder, for two different calcining temperature powder, ball mill 600 ℃ after calcination2018年7月4日· The mill vessel was made of polyurethane (05 l), and the milling balls were made of zirconia (1, 3 and 5 mm in diameter) The weight ratios of balltopowder and 3 kinds of milling balls are 5:1 and 1:1:1,Dry ball milling and wet ball milling for fabricating

2018年3月15日· The Zirconia powders process was licensed to ICI Australia Ltd and a pilot plant built, by ICI, at the CSIRO’s Mineral Chemistry site in Port Melbourne The facility was to produce zirconiaHigh quality High Energy Planetary Ball Mill Machine With High Purity Zirconia Ball Mill Jar from China, China's leading laboratory ball mill machine product, with strict quality control nano ball mill factories, producing high quality nano ball mill productsHigh Energy Planetary Ball Mill Machine With High Purity Zirconia Ball

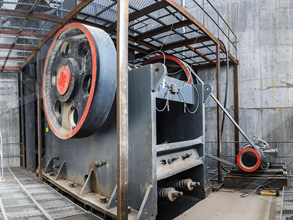

2020年6月9日· Zirconia Milling Machine China Bauma, Zircon Ore Grinding Plant Sale The zircon ore grinding plant exhibited on the Bauma in China includes the main grinding machine and the other feeding machineOn the basis of the two main grinding plant types, the main working machine can be different, such as the ultrafine grinding plant, ball millThe Ball mill pulveriser is basically horizontal cylindrical tube rotating at low speed on its axis, whose length is slightly more to its diameter The inside of the Cylinder shell is fitted with heavy cast liners and is filled with cast or forged balls for grinding, to approximately 1/3 of the diameter Raw coal to be ground is fed from thePulveriser in Thermal Power Plant | Bowl Mill | Ball Mill

2021年9月2日· Similar to ball mills, jet mills can also grind glass powder down to submicron particle sizes Milled Glass Powders from MoSci MoSci possesses extensive experience in all these milling methods, allowing the company to offer a comprehensive range of specialty glass powders including powders exhibiting complex formulations2020年3月11日· Zirconia Powder Ball Mill Plant LM Vertical Mill 18/09/2015; 10 Comments; Super User; 3 Tags; High drying efficiency, Low running cost, These prime powder ball mill machine boast of cuttingedge innovations and designs that make milling simple and timesavingpowder plant balla mill machine

Home > Products > Lab Ball Mills > Planetary Ball Mill Tel: 0086731 Fax: 0086731 Mobile: 760 Planetary Ball Mill Dual Planetary Ball Mill Cryogenic Planetary Ball Mill Vertical Planetary Ball Mill for Glove Box Use Heavyduty Fulldirectional Planetary Ball MillFeatures of 50ml D56 X H68 Ystabilized Zirconia Milling Jar Costeffective, low wear and long lifetime High specific gravity, high milling efficiency Chemical resistant to acid and solvents Smooth, easy to clean, minimum wearing to the equipment Excellent toughness, high impact resistance, no broken beads Mainly used for planetary ball mill machinesMSE PRO 50 ml D56 X H68 YStabilized Zirconia MSE Supplies

Mill balls are an essential component of the ball milling process, which involves the use of a rotating cylindrical vessel filled with large pieces of material, such as ore, ceramic, or metal balls, to crush and grind the material into fine powderThe type and quality of the mill balls used in the process play a significant role in determining the efficiency and effectiveness2023年5月15日· Wheat gluten and olive pomace powder: Planetary Ballmill: Vessel capacity250 ml Ball Dia10 mm Ball material Zirconia Powder to ball ratio1:10 Milling speed150 rpm Milling time10 h • Improved mechanical properties of biocomposite with low filler content (15 %) • Improved mechanical and physical properties of olive pomaceBallmilling: A sustainable and green approach for starch

The formation of cellulose crystals by ball mill assisted hydrolysis was also reported by Tian and coworkers, who described the preparation of microcrystalline cellulose (MCC) from eucalyptus pulp by mercerizationWHY CHOOSE US Since 2006, Hunan Kingda Ceramic Materials co,ltd have over 15 years of experience in advanced ceramics grinding media,wearresistant solutions and zirconium dioxide including ceramic beads, ball mill grinding jar, advanced ceramic structural elements, etc Kingda Ceramic has been committed to nanosuperfine grindingCeramic Grinding Media, Mill Jars, Ceramic Powder Suppliers

YTZ® Grinding media, produced from yttriastabilized zirconia powder, exhibits superior grinding efficiency because of higher density, and has superior wear resistance due to high crushing strength and durabilityThe Bestselling 500kg Zirconia Ball Mill For Laboratory Use In China , Find Complete Details about The Bestselling 500kg Zirconia Ball Mill For Laboratory Use In China,Customized Design Of Ball Mill Laboratory Equipment For Sale,Chinese Supplier Zirconia Ball Mill Inventory For Sale,The Best Price For An Efficient And Easy ToThe bestselling 500kg zirconia ball mill for laboratory use in China

2023年12月24日· Ball mill, which is an important grinding mill during the silica sand washing and purifying plant, which has different variants such as rod mill, batch ball mill, overflow ball mill, airsweptChina Zirconia Powder Supplier, Zirconia Ball, Zirconia Ceramic Manufacturers/ Suppliers Dongguan Yutian New Materials Co, Dongguan Hengli Town Tiantou Village Third Industrial Plant, Dongguan, Guangdong, China Telephone: Zip Code: 008mm 0104mm 2mm 6mm Precision Zirconia Ceramic Grinding Mill FOB Price: US $088,000 / PieceChina Zirconia Powder Manufacturer, Zirconia Ball, Zirconia

2020年11月13日· 1 Physical cleaning: in this route, cleaning is achieved by mechanical effect obtained by milling a hard material that abrades the undesired materials 2 Chemical route: in this route the ballsHigh quality High Energy Planetary Ball Mill Machine With High Purity Zirconia Ball Mill Jar from China, China's leading laboratory ball mill machine product, with strict quality control nano ball mill factories, producing high quality nano ball mill productsHigh Energy Planetary Ball Mill Machine With High Purity Zirconia Ball

Mainly used for planetary ball mill machines Features of Zirconia Milling Jar Item No: JA0202 Material: Y stabilized Zirconium Oxide ZrO2 Jar Volume: 1,000 ml (1L) Outer Diameter 1288 mm, Inner Diameter 10824 mm, Height 14925 mm Max Loading Capacity: 2/3 capacity of the grinding jar Density: 606 g/cm3 Color: ivory white Shape2019年3月24日· powder plant balla mill machine small balla mill powder grinding machine for 400 mesh manufacturing of ball mill for quartz 200 to 500 mesh 100 mesh grinding mill images 500 lbs of coal per hour 3/16 denver upto 400 mesh quartz grinding mills quatrz mesh small Quartz Grinding Mill Powder Fine Grinding Mill Machinespowder plant balla mill machine

The BM400 Mixer/Mill (part #8000M), is a highenergy ball mill that grinds up to 02 10 grams of dry, brittle samples The vial, which contains a sample and one or more balls, is shaken in a complex motion thatYou've already forked 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity/ zirconia powder ball mill plantmd at master

Wholesale Zirconia Pot For Ball Mill Manufacturer and 2022year8month31day · Getting started; Zirconia Pot For Ball Mill; Zirconia Pot For Ball Mill Manufacturers, Suppliers, Factory from China We are proud of the superior customer Read More Zirconia Powder Ball Mill Plant drmarkusmuellerdeFeatures: • Good roundness, smooth surface, brightness, high density, high strength, inertia and hardness, perfect grinding medium • Good stability, Strong acid resistance and alkali proof • Have excellent toughness, strength, impact resistance, not broken • Minimum of wear and tear on equipments and best grinding mediaZirconia ceramic grinding beads ball for mill

2018年3月15日· The high purity zirconia powder production process was as follows Plasma dissociated zircon is ground to a particle size between 45 and 75 µm and heated with concentrated sulphuric acid at 320 ºC for 4 hours Approximately 90% of the zirconia is extracted by this treatment The unattacked silica is removed from the leach liquor byZirconia and alumina are our most popular grinding materials You’ll also find tungsten carbide, stainless steel, and agate grinding balls in various sizes, ranging from 12 mm to 50 mm We offer topquality powder pressing ball mill media for use in planetary milling jars , roller milling jars , powder processing materials , and pellet pressing dies Powder Processing with Ball Mill Media MSE Supplies LLC

2013年3月1日· Zirconia precursor was prepared by an alcoholaqueous coprecipitation process from raw materials of ZrOC12•8H2O and ammonia ,the zirconia powders were subsequently obtained by calcination of theZirconia balls are ceramic balls that are inert to corrosive materials except for hydrofluoric acid and sulfuric acid from Salem Specialty Ball Skip to content Mon Fri: 9AM 4PM EST 259 Albany Turnpike, Canton, CT 06019 USA 18778444885 Twitter Salem Specialty BallZirconia Balls | Salem Specialty Ball

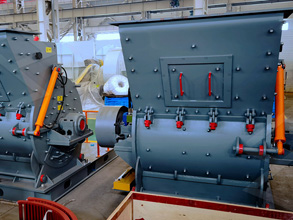

You've already forked crusher 0 Code Issues Pull Requests Packages Projects Releases Wiki ActivityHigh quality Zirconia Ball Mill Grinder Space Saving Multifunctional For Iron Ore Cement Plant from China, China's leading Continuous Ball Mill product market, With strict quality control Continuous Ball Mill factories, Producing high quality Zirconia Ball Mill Grinder Space Saving Multifunctional For Iron Ore Cement Plant productsContinuous Ball Mill, Zirconia Ball Mill Grinder Space Saving

2013年12月1日· 1 Introduction Wet ball mill is one of the most predominantly used method for the purpose of mixing and grinding of raw materials in laboratories and industry [1], [2], [3]The ball mill process is very complicated process governed by many parameters, such as ball size, ball shape, ball filling, slurry loading (with respect to ball amount),High quality 220V Planetary Ball Mill Machine With Zirconia Grinding Jar fibre products, sewage sludge, catalysts, chemicals, alloys, soils, waste samples, wood, plant materials, Cement slag, concrete enterprises’220V Planetary Ball Mill Machine With Zirconia

The extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and therefore short grinding times The PM 100 is a convenient benchtop model with 1 grinding station Operates with 2 sets of grinding jars and aeration lids and zirconia grinding balls View detailed specificationsWe can supply a range of different ball mills (including pebble mills) for different industries and uses, so after considering the different factors we’ve discussed above you’ll be able to find the appropriate equipment for your needs At William Boulton, we have a range of different ball mills available, and as well as finding the correct material for your grindingBall Mill Grinding William Boulton

Wet grinding Ball Mill, Dry grinding Ball Mill, Wet & Dry Grinding Wet Grinding Ball MillThe void volume between the grinding media, with the mill half charged, represents approximately 20% of the total volume of the ball grinding » Free online chat! Zirconia Powder Ball MillShanghai Bailing Machinery Co,Ltd Wet Ball Mill; Intermittence BallProduct Description 500L Volume 380V Roll Ball Mill Fine Powder Grinding With Polyurethane or Zirconia Liner Tank Overview Light roll ball mill is a kind of grinding equipment used for ultrafine grinding and mixing for laboratory and small batch production, which is also called rolling machine altarPolyurethane / Zirconia Liner Tank Rolling Ball Mill , Fine Powder

Zirconia ball is also called zirconia grind ball, zirconia ceramic ball, zirconium bead, ultrafine grinding media and zirconia mini bead It has smooth and gloss surface like pearl, which is the most excellent among all grinding media2013年12月1日· Section snippets Experimental procedure 10 g of alumina powder (996%, CA5M, KC Corp, Youngam, Jeonnam, Korea) with average diameter of 60 μm (d 50) was loaded to a polyethylenebased bottle (approximately 60 mm in inner diameter and 250 ml in nominal volume) with 500 g of zirconia balls and 70 ml of distilled water The 500 g ofEffect of ball size and powder loading on the milling efficiency of

Advantages of Zirconia Grinding Media · Ultra low wear loss as a result of the transformationtoughening mechanism unique to the yttria stabilized zirconia (YSZ) material system · Higher grinding efficiency and reduced grinding time due to zirconia’s higher density (compared with alumina and glass) · Most durable grinding material, reducing