The Steele Smooth Roll Crusher plays a key role in bulk raw material preparation, processing clays, coal fines, coke breeze and gypsumDouble Roll Crushers The double roll crushers are strength wise great and best suitable for crushing any type of ores and rocks whose utility is more in chemical, mining andRoll Crusher and Double Toothed Roll Crushers

A typical application: fine crushing eg from 30 mm feed size to 5 mm product size, approx 80% target particle size largely avoiding fine grain and dust Crushing roll surface2023年11月1日· The paper presents results of extensive investigations exploring the influences of compressive strength, roll peripheral speed, feed particle size distribution,New insights into double roll crushing ScienceDirect

2008年4月9日· The rolls can be smooth, corrugated or toothed and the distance between them (gap) is a key variable parameter In the breakage of urea, the doubleroll crusherSmooth roll crushers are particularly suitable for medium and fine grinding processes, demanding a strictly defined portion of fine grain and a low dust content THE FEEDGENTLE

2023年4月1日· The counter roll differential speed solid organic fertilizer crusher, 1 Hydraulic motor 2 Hydraulic tank 3 Paddle fertilizer transport device 4 Fence 5The smooth double roll crusher is a specialized equipment that mainly uses cobblestones to produce sand and stone materials for construction The smooth double roll crusherSmooth Double Roll Crusher huashengming

Smooth Double Roll Crusher Application Secondary and tertiary crushing of soft to hard ore and minerals with a crushing ratio of 25:1 max for hard and abrasive material andRobust roller crusher and sizer offering to maximise your crushing capabilities Our roller crushers and sizers are built to last, with strong frames and selflubrication systems toLonglasting roller crusher and sizer solutions I

Contribute to lbsid/en development by creating an account on GitHubSmooth Double Roll Crusher Application Secondary and tertiary crushing of soft to hard ore and minerals with a crushing ratio of 25:1 max for hard and abrasive material and 3:1 max for soft and nonabrasive materials The crushing action take place by surface impact of counter rotating plain rolls 8″ Double Roll Crusher US$ 7,000 For sale with its 8 inch bydouble smooth roll crusher for aggregate mining

The rule of thumb for the Double Roll Crusher’s ratio of reduction is 4:1 The simplified design gives these units excellent reliability and requires very little maintenance The crushers are designed with builtin tramp reliefSince patenting the first Single Roll Crusher in 1894, McLanahan has become an expert and leader in the industry in the design and manufacture of single and two stage Roll Crushers The selection process for each application is based on extensive equipment knowledge and a wealth of test data developed in our research lab or through onsiteMcLanahan | Roll Crushers

Manufacturer of Smooth Double Roll Crusher Iron Ore Roll Crusher, Quartz Crusher, Roll Crusher offered by Mechtech Engineers, Vadodara, Gujarat M echtech E ngineers Makarpura, Vadodara, Gujarat GST No 24BXMPP0327H1ZI Call 67% Response Rate Send Email About Us / Our Products /Agitated teeth organic fertilizer granulator or double roll extrusion When livestock and poultry burned products are built into organic fertilizer they can generally be sold for 600 800 yuan / T by comparison the environmental trend price of general compound fertilizer is around 1200 1800 yuan / T so organic fertilizer has the inevitable cost advantage andsmooth double roll crusher for aggregate fertilizer

Double Roll Crusher Of Fertilizer Line, Find complete details about roller crusher,double crusher,roll crusher from fertiliser double roll crusher – sq1co Jul 28, 2015 roll crusher manufacturer india , manufacturer of roll crusher and top manufacturers of Smooth double roll crusher for Fertilizer and AggregateDOVE Roll Crusher also referred to as Double Roller Crusher, or Twin Roll Crusher is highly efficient crushing machine, used in certain applications for primary, secondary and tertiary crushing applications DOVE Roller crushers are highly practical crushers for soft to mediumhard ore and where the final crushed out put is required to be of uniform grainRoll Crusher| Double Roller Crusher |DOVE

Smooth roll crushers are particularly suitable for medium and fine grinding processes, demanding a strictly defined portion of fine grain and a low dust content THE FEED MATERIALS Raw materials, secondary raw materials and byproducts such as coke duff, coal, rock, fireclay, fertilizer, salt, glass and similar productsProgress in RollCrushing BY C Q Payne, New York, N Y On the right, a Roll Crushers is shown in a sectional elevation of the AC singleroll crusher while here below is a cutaway view of the machine, with hopper and part of the near side frame removed to show the crushing chamber The moving elements of the machine consist of the roll, with itsRoll Crushers Top 2022 Models 911 Metallurgist

Fields of Application roll crushers have been installed in plants as primary and secondary crushers for the comminution of raw materials such as limestone, clay, flint clay, coal, coke, phosphate, marl, chalk, and filler material as well as burnt lime, foam concrete, fertilizer and much more Roll crushers with differing tooth2023年2月22日· Tooth roll crusher, also known as double roll crusher, is a versatile equipment used for material reduction in various industries It consists of two cylindrical rolls that rotate in opposite directions, withTooth Roll Crusher: A Versatile Equipment for Material

24 x 60 Mclanahan Black Diamond Double Roll Crusher with Innerstage VBelt Drive Also includes spare set of roll s $58,500 USD Get financing Est $1,101/mo Oak Hill, WV, USA Click to Contact Seller Trusted Seller Roskamp TRC90018 Stainless Steel Roll Crusher 2144807 usedRoll crushers come in different configurations depending on the crushed material and the required output size Some standard roll crushers include singleroll, doubleroll, and tripleroll crushers They can also be designed with smooth or corrugated surfaces on the rollers to provide different levels of crushing action How Roll Crushers WorkRoll Crushers | Williams Crusher

2008年4月9日· Usually the doubleroll type of crusher is used as the size reduction unit in urea granulation circuits This device is constituted by two pairs of rolls that rotate in opposite directions at different speeds The rolls can be smooth, corrugated or toothed and the distance between them (gap) is a key variable parameterDouble Roll Crushers are useful for intermediate size reduction of hard to medium hard materials, such as rock or ore, after processing with a jaw crusher, for final reduction with a pulverizer They also bridge the gap between laboratory and continuous production or pilot plant crushing capacities Especially recommended for assay officesMarcy® Double Roll Crushers – Lavallab

Smooth Double Roll Crushers for Fertilizer and Aggregate: Being global Biomass and briquette crushing machine manufacturers in India, we also specialize in manufacturing Smooth double roll crushers which are widely accepted in industries where narrow spectrum is required like fertilizer and aggregate Smooth double roll crusher2008年4月9日· The doubleroll crusher model, first proposed by Austin et al [15] and lately refined by Austin et al [16], is based on the following assumptions: a) breakage of each size particle occurs independently of the other sizes, b) provided the roll diameter is large enough compared with the feed size and gap, the product size distribution dependsModeling of an industrial doubleroll crusher of a urea

Roll Crushers In Mineral Processing Design and Operations (Second Edition), 2016 623 Roll crusher circuit design Roll crushers are generally not used as primary crushers for hard ores Even for softer ores, such as chalcocite and chalcopyrite, they have been used as secondary crushers Choke feeding is not advisable as it tends to produce particles ofRobust roller crusher and sizer offering to maximise your crushing capabilities Our roller crushers and sizers are built to last, with strong frames and selflubrication systems to reduce your maintenance burdens They offer reliable crushing of materials in the cement and mining industry, including highlyabrasive and sticky ones, andLonglasting roller crusher and sizer solutions I

The Steele Smooth Roll Crusher plays a key role in bulk raw material preparation, processing clays, coal fines, coke breeze and gypsum waste Twin rollers reduce pebbles and plastic lumps to form thin, flat discs,Quad Roll Crusher Size: 20 in x 26 in Two stage material reduction with one pass For friable material Equipped with ID: Quote + FAM 78 in x 60 in Double Roll Crusher FAM Double Roll Crusher Model: ZWBNew & Used Roll Crushers for Sale Savona Equipment

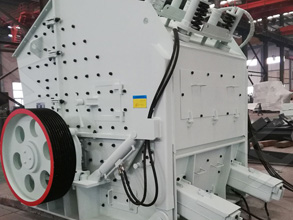

Smooth Double Roll Crusher is used for medium and fine crushing of soft to medium hard material like coal, fertilizer, chalk, clay, limestone, coke, glass etc It can be also used for tertiary crushing of hard material like iron ore, refractory material For better nipping of crushing material, the feed size is limited to 45150 mm(max)2017年4月1日· Abstract Double roll crushers (DRC) have the highest throughputs among primary crushers In the oil sands, the hourly capacity may exceed 14,000 t/h They are preferably used to comminute mediumhard rock or sticky materials An unusual tough particle or unbreakable object may effect substantial dynamic forces in a DRCDynamics in double roll crushers ScienceDirect

Breakage in doubleroll crushers (‘oncethrough’ equip In the breakage of urea, the doubleroll crusher is preferred over ment) occurs instantaneously while the material is pulled into the other comminuting equipment because narrow size distributions, rolls, thus all the particles pass through the set gap [10] low dust and limited noise generation areCPC Smooth Roll Crusher Application Comminution of hard and mediumhard material (lime stone, magnesia, salt, fertilizer, coke etc) Throughput up to 500 mt/hr, depending on material characteristic and particle size A typical application: fine crushing eg from 30 mm feed size to 5 mm product size, approx 80% target particle size largely avoiding fineSmooth Roll Crusher CPC GmbH Crushing Processing

Overview Mechtech SDRCs designed for primary, secondary and tertiary crushing are best suited for achieving the reduction ratios of 4:1 It is best suited for producing finer products SDRCs are widely used and referred for their excellentCONTACT US SALES OFFICE ADDRESS Kawasan Perkantoran Metro Indah Mall blok D35 Jalan Soekarno Hatta Bypass Area BANDUNG City JAWA BARAT Province – INDONESIA PHONE OFFICE : 022 (HOTLINE) SALES : 085222 / 085277 EPROC / PENGADAAN : 085211222091Double Roll Crusher PTVALTEKINDO GLOBAL INTERTEK

The smooth double roll crusher is another breakthrough in the field of sand and gravel aggregate production equipment manufacturing This equipment uses two motors to drive two pairs of roller shafts to squeeze and grind materialsThe roller crusher is mainly used for fine crushing operations with raw materials smaller than 80mm and finished productWe produce highperformance double roll crushers for your applications Skip to content Mining Ore Crushing Equipment Expert Henan Province, China Zhengzhou West Industrial Zone, +86 sales@moledive Mon Fri: 9 Cone Crusher; Sand Making MachineMoleDive Double Roll Crusher Your Trusted Production Factory

Design and production of an indigenous roll crusher from locally available materials for low hardness rocks was carried out in this work The throughput capacity of the machine was 143tonnes/hour The theoretical efficiency of the double roll crusher when crushing limestone was 60% while that of kaolin was 80%Roll Crusher The smooth Roll Crusher is reliable and highperformance, offering numerous advantages over conventional roll crushers The MechProTech HighPressure Grinding Roller Crusher comes with aRolls Crushers – MechProTech

The DRCDouble roll crusher is designed in such a way that the rollers can be reversed from standstill with extremely high starting torques Foreign objects that cannot be crushed are automatically released from the crushing chamber This is done with the help of the hydraulic gap adjustment, which can open and close the crushing gap fastContribute to chengxinjia/ development by creating an account on GitHub/ fertiliser double roll crushermd at main GitHub

2022年10月14日· The double roll crusher is an essential equipment in major sand and gravel factories, and is often used in sand and gravel production lines and sand production lines Double roll crusher is a kind of equipment often used in various metal, nonmetal, chemical, coal, electric power industries Compared with other crushers, the double rollSmooth Double Roll Crusher FTM Products Made In China, China Manufacturer Smooth Double Roll Crusher, Roller crusher, Double Roll Crusher Roll crusher, also known as roller crusher, belongs to traditional crushing equipment It is mainly used for fine processing of material particles As the main working part, the two cylindrical rollersSmooth Double Roll Crusher FTM (China Manufacturer)

2022年2月10日· Doubleroll break is also called doubleroller crusher This series of doubleroll crusher can be used for finely crushing various high and medium hardness ores and rocks in industrial sectors such as mineral processing, chemical industry, cement, refractory materials, abrasives, and building materials Especially in the construction2008年4月1日· In addition, for safe and reliable operation of the smooth doubleroll crusher, the influence of nip conditions, rotation speed and feed material characteristics on the crushing and bearing forceModeling of an industrial doubleroll crusher of a urea

10″ to 12″ Double Roll Crushers US$ 27,000 The rolls crushers we sell are used in mining and parallel industries; a double rolls crusher is a common type of equipment used as a primary crusher for sizing ore Roll crushers are used for sizing sintered coals, soft and medium hard rocks, fertilizers and salts2018年9月12日· Double roll crusher (also called twin roll crusher) is composed of two cylindrical rollers as the main working mechanism (Figure 1) When working, the two round rollers rotate in opposite directions, and the material (ore) is crushed by the friction between the rollers, which rolls the material into the crushing cavity formed by the two rollersDouble Roll Crusher | Henan Deya Machinery Co, Ltd