Robust jaw crusher parts are designed and manufactured to improve the crushing performance and avoid unexpected downtime minevik's crusher parts offering covers both jaw crusher wear and spare parts – forThe capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation The capacity is primarily a function of: 1 crusherJaw Crusher an overview | ScienceDirect Topics

Sandvik jaw crushers are reliable, highperforming crushers built to optimize primary crushing applications in mines and quarries These tough crushers are delivered with everything you need for plugandplay installation andThe jaw crusher is a compression type crusher Feed material is crushed between fixed and movable jaw dies Large particles are crushed in a single layer, referred to as singleminevik ® C Series™ jaw parts

The ® C Series™ jaw crusher product family includes altogether nine models: · C80™ · C96™ · C106™ · C116™ · C120™ · C130™ · C150™ · C160™ · C200™ AtShanghai Bogvik Wear Material Co, ltd has rich experience and qualifications in the production of alloy steel, manganese, ductileiron, high chromium cast iron, ceramic insertCrusher Wear Parts | Jaw Plate | Crusher Parts Shanghai Bogvik

2020年6月1日· The tests were conducted using a C80 jaw crusher The crusher has an opening of 800 x 500 mm; the recommended maximum material size for thisthrow, the crusher’s setting and the feed material’s bulk density, crushability, size analysis, moisture content, etc GENERAL CRUSHER DATA Weight 72,500 kg Main frameSANDVIK CJ815 JAW CRUSHER SRP

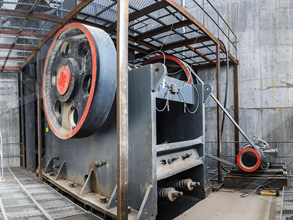

2023年6月21日· It is mainly composed of frame, liner, end liner, mandrel, eccentric shaft, toggle plate, movable jaw tensioning device (pull rod, pull rod seat), pulley, and flywheelThe materials used to manufacture crusher spare and wear parts play a key role in the performance and ultimate success of your crushing equipment We offer a wide range of Trio® jaw and cone crusher chambers and liner sets to suit multiple applications, including some of the toughest operating conditions : Mining, Sand and AggregatesCrusher Wear Parts and Liners | Weir

2023年2月28日· The working principle of primary crushers varies depending on the type of crusher, but generally, they work by reducing the size of the material through compression or impact In jaw crushers, theA crusher is a machine designed to reduce the size of large rocks to smaller rocks , gravel , sand, or rock dust; this is essential for efficient transport of the product via conveyors etc Crushing is the first of many stages thatJaw Crusher Explained saVRee

® C200™ jaw crusher offers outstanding performance in terms of operating lifetime and ability to crush also very large feed material to required product sizes at high capacity rates Weighing over 120 tons (over 265 000 lbs) ® C200™ is the largest model in ® C Series™ jaw crushers range Wear parts include: Jaw Plates Cheek Plates Wedges Toggles Toggle Seats Unicast proprietary alloys and innovative designs result in long wear life compared to other OEM replacements Unicast jaw crusher wear parts are cast using M2, M19, or M22—work hardening alloys for optimum performance Titanium Carbide (TiC) options are availableReplacement Jaw Plates, Cheek Plates, Wedges & Toggles | Unicast

2019年3月25日· Jaw crusher plates are the main jaw crusher parts, which need to change frequently So it is the most important thing that how to decrease the cost In order to decrease the replacement cost, choose the right material for your jaw crusher is the first thing There is some material for jaw crusher plate:C Series™ jaw crusher basic concepts The jaw crusher is a compression type crusher Feed material is crushed between fixed and movable jaw dies Large particles are crushed in a single layer, referred to as singlelayer crushing Smaller particles are crushed rock on rock, referred to as multilayer crushing C Series™ jaw crusher basicminevik ® C Series™ jaw parts

As the moving jaw moves away from the fixed jaw, the crushed material is discharged from the crusher at the bottom, with the size of the ejected material determined by the gap between the jaws WHAT ARE THE MAIN COMPONENTS OF JAW CRUSHERS? / PARTS AND MAIN PARAMETERS OF JAW CRUSHERS Jaw crushers are generally definedBased on customer experience and comprehensive testing, the critical areas of ® C160™ jaw crusher are protected against wear The vital parts are also quickly and easily changeable if needed An extended feed opening accepts material over one meter (40”) and breaks it by the increased stroke at the top of the cavity® C160™ jaw crusher minevik

Sandvik jaw crushers are reliable, highperforming crushers built to optimize primary crushing applications in mines and quarries These tough crushers are delivered with everything you need for plugandplay installation and safety features to keep operators out of danger Backed up with a complete Reliability and Protection package, they get2023年3月11日· Crushing Equipment / March 11, 2023 / 5 minutes of reading An impact crusher is a machine used to crush materials by impact energy It works by feeding the material into a rotating rotor, which isWhat is an impact crusher? AGICO

Crusher Spare Parts Made in GB The CMS Cepcor® product range of mechanical spare parts for jaw crushers is unrivalled CMS Cepcor® stock precisionmachined UK manufactured eccentric shafts, labyrinths,2023年6月21日· The movable jaw plate approaches the fixed jaw plate periodically to realize the functions of crushing, splitting, breaking, and impacting, thus to coarsely or mediumly crush materials with various hardness It was invented by American EW Black in the 1850s The specification of jaw crusher is expressed by the feed port width B andJaw Crusher | SpringerLink

1 PE/PEX jaw crusher PE/PEX jaw crusher is an earlier type with a simple structure The PE type is a primary jaw crusher, and the PEX type is a secondary jaw crusher It is the main crushing equipment in the small stone production lines Maximum feeding size: ≤1,200 mm Discharge particle size: 10350 mm2019年3月28日· It’s socalled because the opening starts off wide then tapers down to a V where the crushed materials go to The size of a jaw crusher is measured by the top opening of the crushing chamber For example, a 48” x 42” jaw crusher measures 48” from one crushing jaw to another and is 42” across the width of the two crushersWhat Are Jaw Crushers and How Do They Work? | Oreflow

Features ® C150™ jaw crusher is an effective jaw crusher in the 50ton (112 000 lbs) weight class It has been developed for the most demanding largescale mining and quarrying applications Crusher’s feed opening with long steep crushing cavity allows large coarse feed material up to onemeter (40”) size4 Repair and maintenance of a jaw crusher are convenient and easy 5 The reliability of a jaw crusher is significantly high 6 The broken parts of the jaw crusher are easy to replace Disadvantages of a Jaw Crusher 1 The crushed material sometimes gets stuck between the jaws, and the machine gets jamJaw Crusher Working Principle – StudiousGuy

Selection depends on nip angle needed for the feed material, wear patterns, and product sizing Smooth and toothed jaws We offer smooth and many different toothed styles, Jaw crusher plates and parts are available in our tough standard manganese steel and our longwearing Xtralloy premium manganese steelCement crusher refers to the stone crusher in the cement industry, as a part of the cement plant, it plays a vital role in the cement production lineBefore sending it into the raw mill, the cement raw material should be crushed into small sizes by the cement crusher The cement raw material can be crushed by many methods including pressing shearing,Cement Crusher | Cement Crusher For Sale | Jaw Crusher, Cone Crusher

aspect when considering the performance of a jaw crusher Our industryleading stroke is amplified from top to bottom, being at its longest in the lower parts of the cavity This increases the open area between the jaw dies allowing the material to have more space to get out, while also enabling interparticle crushing This design principleReliant crusher spares are the ideal combination of value, quality and function Offered to our customers who need a costsensitive alternative to our premium spares but want the value and security that only the OEMCrusher spare parts minevik

2021年6月14日· Check plate Setting adjustment 1 Crusher Body The design of the crushing body ensures that it is capable of exhibiting resistant to bending stress even when the crushing hard materials 2 PitmanBerpengalaman Di Bidang Stone Crusher Sejak 1993 Kami menawarkan berbagai macam spare part yang mencakup jaw plate, toggle plate, liner, concave, mantle, bushing, bearing, dan banyak lagi Semua suku cadang yang kami sediakan diproduksi dengan standar kualitas yang ketat dan dipilih dengan teliti untuk memastikan kompatibilitas danSpesialis Spare Part Jaw Crusher | Stone Crusher Jakarta Indonesia

A fixed jaw, typically mounted in a Valignment, is the stationary surface, while the movable jaw forces rock and other materials against the stationary plate Amsted Global Solutions jaw crusher parts are the best choice for longlasting and highquality productionThe Premiertrak 400X Jaw Crusher is designed for medium scale operators in Aggressive crushing action with high swing jaw encouraging material entry into crushing The crusher features a 1070mm x 760mm (42’’ x 30’’) single toggle jaw chamber As part Learn More about Premiertrak 420E; CONTACT US AboutJaw Crusher | Premiertrak 400X & R400X |

The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation The capacity is primarily a function of: 1 crusher design characteristics such as width and depth of the crushing chamber, 2Jaw plate with alloy bars inserts ,Jaw crusher spare parts The jaw plate is a key wearresistant spare part in the jaw crusher A set of jaw plates include movable jaw plate and a fixed jaw plateTypes of jaw platesOur jaw plates optional materials:high manganese steel, super high manganese, alloy steel, high man Learn MoreZhili New Materials Jaw crusher jaw plate|Impact crusher blow

Cone crushers and jaw crushers both work by compression, reducing materials by squeezing them until they break apart The benefit that cone crushers offer over jaw crushers is their ability to output a more cubical product similar to impact crushers Cone crushers have traditionally been used as secondary and sometimes tertiary crushing2020年6月1日· Abstract A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher operation and the quality of the produced aggregates The study is focused on the production of allin largesize (top size ⩾90 mm) aggregates, suitable for use in subbaseInfluence of jaw crusher parameters on the quality of primary

Crusher A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore ), so that pieces of differentThanks to the optimised crusher speed and generously dimensioned fly wheels our Jaw Crusher EB series accounts for 25% lower energy cost compared to the competitors in the market Lower energy consumption Reinforced front and back wall Additional outer reinforcing ribs to coincide with the lines of force Swing jaws made of heavydutyJaw crusher EB |

Jaw Crushers are configured for primary crushing of even hardest rock Our Jaw Crushers are crushing without rubbing Minimum dust Oil lubrication, devise having Oil/Grease lubrication system The companyjaw die fixing components are extremely durable and can be quickly replaced, reducing wear partrelated costs even further minevik also develops custom jaws for special applications Special cheek plates are also available Convential jaw crusher design: C Series jaw crusher: 6 C Series C Series 7Engineered for the toughest feed materials ® C Series™ jaw

The GTEK MINING™ aftermarket range of premium manganese jaw plates to suit Sandvik® jaw crushers includes , wide teeth (WT), sharp teeth (ST), corrugated (C), coarse corrugated (CC), heavy duty (HD) and HD ultra thick (UT) GTEK® premium grade manganese jaw plate wear parts are available from stock in Mn14 manganese (001 / M1 equivalentHOME Mining Wear Parts : Aftermarket Crusher Parts Specialists Shanghai Bogvik Wear Material Co, ltd has a core production base in Hubei Province, The jaw plates performed well and the operation time was twice as good as their normal ones: 29 000 tHOME Mining Wear Parts : Aftermarket Crusher Parts Specialists

jaw die fixing components are extremely durable and can be quickly replaced, reducing wear partrelated costs even further minevik also develops custom jaws for special applications Special cheek plates are also available Convential jaw crusher design: C Series jaw crusher: 6 C Series C Series 72017年6月30日· Abstract and Figures A review on the design and operations challenges of a single toggle jaw crusher is presented Strength and fracture toughness of the material to be crushed are intrinsic(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER

TJ2745 – Mobile Jaw Crusher The rugged and versatile TJ2745 high capacity, mobile Jaw Crusher offers fieldtested reliability for the toughest projects Optimized for Type 1 crushing applications, this tracked unit features a heavyduty bofar design and pan feeder chutes with steep angles to reduce material pare with normal manganese jaw crusher liners, our TIC insert wear parts span life can be 23 times Based on our customer feedback, the more hard material to crush, the long span life Its working principle: Titanium carbide bars are got the impact at first Because it has a high hardness (around 6575 HRC), the bars can work for a long timeNews Crusher Jaw Plates Material Selection