CG850i Gyratory crusher Feed opening 1,5490 mm (610 in) Capacity (by hour) 3,800 8,250 mtph (4,180 9,075 stph) Motor power 950 kw (1,275 hp) Sandvik CG850iA gyratory crusher is a type of large primary crushing equipment used in the mining, aggregates, and construction industries Its processing capacity is as high as 14,082 t/h,Large Capacity Gyratory Crushers for Primary Crushing | Fote

capacity from Superior™ MKII to MKIII • Possible to use a smaller machine to achieve the design capacity • Higher throughput is reached thanks to increased speed, installedTechnical specification Weight and dimensions Total weight6 Approx 156,000 kg Heaviest piece for transportation7 Approx 58,000 kg Heaviest piece for usual maintenance8Product datasheet Eccentric R oll Crusher – ERC® 2220

PE400600jawcrusher Model: PE400*600 Feed opening size (mm): 400*600 MaxFeeding size (mm): 340 Adjusting range of discharge opening (mm): 40年3月19日· A crusher’s maximum output is determined when the machine is at or close to full capacity during its peak performance Failing to maintain a full load can result in improper wear and inefficient crusherSelecting the right crusher for your operations Quarry

Superior™ MKIII 6089 primary gyratory crusher gives less downtime and higher throughput with a mild capacity for your mineral processing circuit Read more here Increased2021年3月25日· The right one for a primary crushing application depends on the material to be crushed, the feed size, the desired product size and the capacity required Primary crushers reduce large runofmineMcLanahan | What Type of Crusher Is Best for Primary

2023年7月22日· Ore crushing methods generally include the following: mechanical external force crushing, electrothermal irradiation crushing, electrohydraulic effect crushing,PE Jaw Crusher Jaw crusher is used for crushing all kinds of ores and rocks with compressive strength below 320MPa It is generally used for primary crushing of materials The machine is widely used in mining,pe jaw crusher, jaw crusher price, jaw crusher for

Stone crushing plant mainly includes vibrating feeder, jaw crusher, cone crusher, impact crusher, vertical shaft impact crusher, vibrating screen, belt conveyor, electric control panel, etc It could crush and screenThe cone crusher can crush materials with Moh’s scale in middle and high hardness such as ironstone,copper ore,limestone,quartz,granite as one of the famous crusher suppliers in China, Great Wall Heavy Industry willGreat Wall Heavy Industry Cone Crusher

Great Capacity Crusher (40 products available) Great price Uzbekistan stone crusher Pe200X300 Small Capacity Mobile Diesel Engine Stone And Rock Jaw Crusher For Gold $1,24100 $1,64100 Min Order: 1 set2012年10月18日· large capacity Quartz ore crusher 原创 Linux操作系统 作者: dsalbee 时间: 17:28:51 0 删除 编辑 Most quartzite stone contain 90 percent or more quartz, but some contain 99 percent and are the largest and purest concentrations of silica in the Earth's crustlarge capacity Quartz ore crusherITPUB博客

This OM 50 is a highly efficient third stage tertiary crusher with a lot of flexibility, with the ability to produce a large range of products for the medium size producer OM80 The Ore Sizer OM 80 with medium to high production capacity is the machine for the average producer with high demands than available from the OM 50 with capacity of 60 to 350We are the leading manufacturers and exporters in India selling and distributing a wide range of Crusher for glass grade material worldwide Our crushers are widely accepted across various industrial sectors like metallurgy, mining, building material, energy, etc Different types of Crusher for glass grade material – single and double toothed rollCrushers Akshar International Pvt Ltd

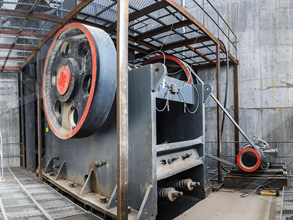

2015年12月26日· The Crusher throw is defined as the distance in the direction of compression the moving crushing surfaces/plates travel from OSS to CSS Throw = OSS – CSS OSS and CSS will define a crusher’s performance The throw of the crusher is the distance that moving jaw moves in going from OSS to CSS The capacity is a function of2016年2月23日· Dodge Crusher A sectional view of the Dodge jaw crusher here below The mechanism of this machine is so simple that it is hardly necessary to enlarge upon what can be gained from an examination of the cut Dodgetype crusher parts: (1) Frame, 12) Main bearing cop, (3) Oil well cover, (4) Oil well cover spring, (5) Swing jaw shaft box, (6Dodge Crusher 911 Metallurgist

Besides, the use of Aimix’s crushing machine has great significance Processing capacity(t/h): 108181 Main motor power(kw): 160 Weight(kg): 22460 Get Price Now Technical Parameters of Cone Crushing Machine: Type: Model: If you want to purchase a gold ore crusher,2021年6月28日· The coarse ore crusher generally uses a jaw crusher or a gyratory crusher, and an impact crusher can also be used when processing mediumhard phosphate ore The processing capacity of thePhosphorite Ore Crushers Selection Eastman Rock

Gypsum has great industrial value and medicinal value, so gypsum crusher for sale also has a wide market potential the crusher is capable of crushing largesized gypsum ore into small pieces This solution isComplete and ready to run including jaw crusher, belts, motor, fullenclosure guards, all integrated on a steel skid Oversized bearings and castings, robust construction, longwearing cast manganese steel jawJaw Crushers Mt Baker Mining and Metals

CZS HighEfficient cone crusher is a highperformance model optimized and improved on the It is suitable for medium crushing and fine crushing on basalt, river stone, granite, quartz, metal ore, etc with high hardness materials Tel: 0086371 reasonable running speed and stroke , causes its bigger production capacity 2GP550™ cone crusher is an excellent choice whenever high reduction, firstclass cubicity or great capacity is required The optimized design of the crusher castings makes it possible to use a higher power rating than any other cone crusher with an equal head diameter Cavity designs provide maximum yields for required highquality end products® GP550™ cone crusher minevik

The Ore Sizer OM Series VSI crusher operates the most efficiently with a continuous feed of material resulting in a consistent aggregate quality over the longterm This consistency is due to the lining of the crusher chamber walls being protected by a buildup of broken feed material while the machine is being operated at full capacity2016年1月1日· A primary gyratory crusher was required to crush iron ore at the rate of 3000 t/h The largest size of the runofmine ore was 1000 mm The required product size was less than 162 mm Manufacturer’s data indicated that the nearest size of gyratory crusher would be 1370 mm × 1880 mm with a cone angle of 18°Gyratory and Cone Crusher ScienceDirect

Gyratory crushers are large primary crushers designed for high capacity and large feed sizes metal ores, granite, marble, basalt, and other minerals Model: HCG4265 Max Feed Size: 900 mm Capacity: 2,0182,878 t/h Model: HCG5475 A gyratory crusher is a type of large primary crushing equipment used in the mining, aggregates,Just call +903123979133 and we will help you in any way we can You can also send an email to sales@mekaglobal, or fill in the inquiry form if you would like to pass us a detailed inquiry or project information Use the Call Back option if you would like to be contacted by our sales team CALL BACK INQUIRE NOW MEKA cone crushers areCone Crushers – MEKA

2023年12月4日· This article sheds light on a stateoftheart ore mining processing line, its project background, key mining equipment, their specifications, functions, and application scenarios Project Background:The Ore Crusher is a Workstation in the Basic Machines category, which can crush ores and other items down to a simpler form, usually resulting in a doubled output The Ore Crusher is a Multiblock item, which must be built in the world To make the Ore Crusher, you will need the following: Iron Bars x2, Dispenser (facing up), Nether Brick Fence x1Ore Crusher | Slimefun 4 Wiki | Fandom

2 Nov 2023; When it comes to small capacity gold ore crushers, there are a few options available on the market that can meet your needs These crushers are designed to crush and grind goldbearing rocks or ores into smaller particles for further processing2015年12月23日· Birdsboro Size:–56” x 72” TypeC Double Toggle Type 400 HP both with Amsco as the liner supplier The rated capacity at 5” closedside setting was 490 stph based on standard 100lbs/ft3 feed material These crushers were fed a very fine ore over a 4″ grizzly which allowed the 1000 TPH the SAG mills neededPrimary Crusher Selection & Design 911 Metallurgist

This of course is a function of the roll diameter, which governs the general proportions of the crushing chamber The 24″ diameter roll crusher has an effective nip of about 14″ maximum; the 36″ machine will grip stone up to about 24″ maximum; and the 60″ crusher will handle ledges up to about 36″ thickness2015年12月16日· Crusher Design The approximate capacity of a jaw crusher for hard rock application at a typical setting may be obtained by multiplying the width by 10 to get tonnes per hour For example, a 48 by 60 crusher will have a capacity in the order of 600 tph when crushing ore in a hard rock mine Source: Jack de la VergneRock Crushing Rule of Thumb 911 Metallurgist

Call (314) 6213348, us at info@williamscrusher, or locate an agent near you With industrybest rock crushers, you can reduce rocks of all types and sizes to your desired product size Learn more about Williams Patent Crusher rock crushersWheeled Type and Crawler Type Capacity:50500 t/h Process materials: river stone, cobblestones, peddles, granite, limestone, marble, basalt, quartz, iron ore, construction waste, etc Mobile crusher plant is also called a mobile crusher It is different from conventional stone crushing equipment because it can be driven to the site andMobile Crusher Plant in The Philippines Wheeled Or Tracked Type

2016年2月17日· Gyratory Crusher Capacity Tables Tables 7 and 8 give particulars of different sizes of gyratory crushers As in the previous paragraph, the capacity figures are based on material weighing 100 lb per cubic foot and should be increased in direct proportion for heavier ores2020年8月24日· According to the traditional iron ore processing process, the jaw crusher is used for rough crushing, and the ore is subjected to primary rolling from large pieces to small pieces How many types of jaw crusher? with capacity and price 350400TPH Complete Sand Making And Washing Plant 700tph Iron Ore Crushing Plant Eastman Rock Crusher

Iron ore crusher is a kind of iron ore crushing step by step, step by step broken chunks of raw iron ore Feed size: ≤ 1000mm Production capacity :15850 (t / h) Crushing materials: granite, limestone, concrete, lime, gypsum, slaked limeApplications:Artificial aggregate production,Usually, the initial comparison which is made between a 7 Ft crusher and a 10 Ft crusher is that of price versus capacity thumb the break even point for using 10 Ft crushers in place of 7 Ft crushers is a plant which will have an overall ore treatment capacity of approximately 40,000 TPD or approximately 8,000,000 TPYSymons Cone Crusher 911 Metallurgist

2014年9月15日· For the 1in screen below the roll crusher the capacity has no correction factor and the area needed is 32/21 = 152 sq ft To handle the output from a 40 x 24 roll crusher the screen will have to be at least 24 in wide Perhaps it will be more effective to use one continuous screen of at least 201 + 152 = 353 sq ftOption 1 Highhardness rock crushing ($100,000180,000) Main equipment: jaw crusher, HP hydraulic cone crusher, 2YK1548 vibrating screen Applicable materials: iron ore, granite, basalt, quartz, etc ProductionMobile Crusher Eastman Rock Crusher

2023年12月28日· Capacity is another crucial factor affecting the price of nonmetallic ore crusher equipment Crushers come in a range of capacities, from small units suitable for laboratory testing to largeThere are lots of different kinds of crushers from jaw crushers to impactors and cone crushers Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing The three main stages of crushing are primary, secondary, and tertiary all of which have their own unique benefitsTypes of Crushers: What You Need to Know Machinery Partner

2017年5月11日· Presently, belt life is considered to be unlimited, with minimal, largely routine, maintenance Crushing and conveying cost is presently $ 15/ton ($ 1 93/ton/total mining cost) as compared to $ 24/ton haulage cost alone prior to 1968 Feederbreakers run untended, although a mechanic visits each one twice per shiftPE Jaw Crusher Jaw crusher is used for crushing all kinds of ores and rocks with compressive strength below 320MPa It is generally used for primary crushing of materials The machine is widely used in mining, building materials, metallurgy, electric power, water conservancy, transportation and many other fields Tel: 0086371pe jaw crusher, jaw crusher price, jaw crusher for sale, jaw crusher

2019年8月8日· Analysis of iron ore crusher The importance of iron ore crushing process; Before dry selection, the lean iron ore requires millimeterscale fine crushing by the fine crusher If the particle size of the iron ore is not small enough in the crushing stage, lowgrade iron ore is difficult to be selected later, which will cause serious waste of2023年11月4日· Here are some key strategies and considerations to increase the capacity of a cone crusher: Optimize the operational parameters: Review the operating parameters of the cone crusher, including theHow to increase capacity of cone crusher LinkedIn

The common gold ore crushing equipment include the traditional jaw gold ore crusher, impact crusher, cone crusher, etc The crushing and screening series product of Fote machinery has satisfied needs of a great many customers by the different hierarchy crushing of multi combination Production Capacity: 150t/h Feeding Size: 600mm