Primary gyratory crushers – ideally suited to all highcapacity primary hard rock crushing applications Jaw crushers – we have more installed jaw crushers than anyone in the2020年10月27日· The jaw crusher is the first stage in the crushing and screening process, the main purpose of this stage is to crush the rock into a conveyable size In addition toDesigning a Crushing & Screening Plant – Part I Primary Jaw

The primary configuration comprises a Primary Jaw, Secondary Impactor or Tertiary Impactor, and a 3 decks screen Its power is sourced from a robust 230 kW motor and a2014年5月8日· Setting up an underground primary crushing plant requires careful planning Here's how to choose between jaw and a primary gyratory crusher The required capacity defines the size and type ofGoing underground: Jaws or a primary gyratory? minevik

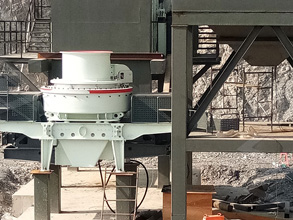

The greatest advantages of European Type Crusher are that the final products are cubeshaped and welldistributed Besides, there are no cracks in products Features 1 Application from one single mobile plant to2020年6月1日· This paper presents a parameter study investigating the effect of feed and jaw crusher parameters on the quality of aggregates produced from singlestageInfluence of jaw crusher parameters on the quality of

Find out all of the information about the Henan LIMING Heavy Industry Science and Technology product: jaw crushing and screening plant Contact a supplier or theJaw Plants Cone/Screen Plants Rugged Reliable Ready for Anything Combine the rugged reliability of our jaw crushers with a high production portable primary crushingPortable Crushing & Screening Technology Corporation

2017年6月30日· The outcome of the result was used to redesign and develop a prototype crushing machine with better output crushing pressure of 131×10⁵ kN/m² and capable of crushing 425–569 kg of rock2019年1月1日· Jaw crusher 1 Introduction Construction and demolition waste (CDW) is mainly composed of cementbased materials such as concrete and mortar, but oftenConcrete aggregates properties crushed by jaw and

Inside the jaw box of a jaw crusher Gyratory crushers Gyratory crushers can be used for both primary and secondary crushing They are similar to cone crushers as they both have coneshaped rotating shafts The spinning shaft is used to crush the material against the wall of the crusher Reduction ratio = 8:1 Cone crushersjaw crusher PE series stationary primary limostone Capacity: 1 t/h 800 t/h Motor power: 55 kW 220 kW Opening height: 150 mm 1,200 mm Product Description PE series jaw crusher is usually used as primaryJaw crusher, Jaw crushing and screening plant All

Big materials are fed to the jaw crusher evenly and gradually by vibrating feeder through a hopper for primary crushing After first crush, the material will transferred to impact crusher by belt conveyor for secondary crush; the crushed materials will then transferred to vibrating screen for separatingIn this completely portable facility, GNRK 60 jaw crusher series is used as the primary crusher and a special designedimpact crusher is used as the secondary crusher General 640, whose main purpose is to crush the stones and mineral materials with high hardness levels in the mobile system to get the desired size, is an ideal crusher facility for stoneJaw crushing and screening plant General 640 DirectIndustry

4432 HiPro Primary Jaw Crusher mounted on civil foundations at a 200 TPH Crushing Plant HiPro Series Primary Jaw Crushers are among the most advanced Crushers in the world We have turned the conventional “Single Toggle” crushing technology upon its head with the unique “Inverted Toggle Plate” technology Our crushers are StrongerJaw crushing and screening plant stationary primary secondary Add to favorites Mobility stationary Other characteristics primary, secondary, tertiary, for mineral material, fine, verticalaxis, horizontalshaft Capacity 150Jaw crushing and screening plant TTC Mühendislik stationary

Jaw crushers are used mainly in first stage, primary crushing applications and are ideal for use in quarries and recycling demolition operations The two main types of jaw crusher produced by Parker are both single toggle designs with the upthrust toggle RockSizer / StoneSizer model and downthrust toggle RockSledger modelWe can provide you the complete stone crushing and beneficiation plantWe also supply standalone crushers, mills and beneficiation machines as well as their spare parts Primary and secondary crusher Description : Pa6d6d primary impact crusher , incdesigned as a primary crusher for either quarried high performance primaPrimary And Secondaryprimary and sendary crusher stone MC WorldINC

2016年7月12日· At the Ross shaft of the Homestake mine, the primary crushing is done by two AllisChalmers size 8 gyratories They are driven by 70hp motors and reduce the ore to 4½ in Secondary Crushing Secondary crushing may be done by jaw or gyratory breakers or by cone crushersFind out all of the information about the Polygonmach product: jaw crushing and screening plant Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of sale Exhibit with us stationary primary secondary AddJaw crushing and screening plant Polygonmach stationary / primary

Find out all of the information about the OPT Makine product: mobile crushing and screening plant Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of saleFind out all of the information about the Fabo Crushing Screening & Concrete Plants product: jaw crushing and screening plant MCK95 Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of saleJaw crushing and screening plant MCK95 DirectIndustry

Find out all of the information about the Polygonmach product: jaw crushing plant PMJI the PMJI plant features a feeding hopper with vibrating feeder, PJC60 Primary Jaw Crusher, PSI Secondary Impactor or PTC1275100150 Tertiary Impact Crusher, bypass conveyor, feeding conveyor, 3 decks vibrating screen,2016年3月10日· Crushing Plant Flowsheet & DesignLayout In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2in size, but they work much more efficiently if their feed is ½ in or less Before the advent of the Symons coneCrushing Plant Flowsheet & DesignLayout 911 Metallurgist

Jaw crusher,Jaw crushers,Primary crushers,Jaw breakers,Mobile The Jaw crusher is used for Primary crushers and Secondary crushers for crushing all kinds of minerals and rocks with compressive strength less than 320 mpa ThereFind out all of the information about the Fabo Crushing Screening & Concrete Plants product: jaw crushing and screening plant FTJ1175 Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of saleJaw crushing and screening plant FTJ1175 DirectIndustry

2016年2月26日· The term “primary crusher,” by definition, might embrace any type and size of crushing machine The term implies that at least two stages of crushing are involved, but in many cases the machine which performs the function of initial crusher is the only crusher in the plant The factors influencing the selection of a crusher for this serviceJaw Crusher is ideally suitable as primary and secondary crusher for material with compression strength less than 320Mpa Jaw Crusher is of high crushing ratio, larger capacity, welldistributed final product size, simple structure, reliable performance, convenient maintenance, lower operation coJaw crushing and screening plant Henan LIMING Heavy

primary, secondary, highcapacity, for mineral material, fine, for Max: 300 t/h (184 lb/s) Min: 100 t/h (61 lb/s) Description K series mobile crusher K SERIES MOBILE CRUSHING & SCREENING PLANT is researched to meet customers’ demand on high quality and high output, and it is widely jaw crushing plant KJ1251 mobile primary forJaw crushers – we have more installed jaw crushers than anyone in the world The leading choice due to their high reduction ratio and heavy duty design Cone crushers – capacities available to suit all secondary, tertiary or quarternary crushing applications High performance technology Impact crushers – primary and secondaryCrushing and Screening Handbook AusIMM

KE6001 Mobile Primary Crushing Plant Feeding Equipment: TSW0936 vibrating feeder Crushing Equipment: PE600×900 jaw crusher Max Feeding Size(mm): 500 Output(t/h): 90180 Overall Dimension:2 Adopted separated designs of side walls, front and back walls for frame, replaced welded machine with bolted fastening, the plant is more stable 3 Improving the chamber’ s structure, optimizing trajectory parameters of moving jaw, the equipment takes advantages of larger crushing stroke and higher production efficiency 4Jaw crushing plant C6X100 Henan LIMING Heavy Industry

Find out all of the information about the Henan Baichy Machinery Equipment Co, Ltd product: jaw crushing and screening plant MF1010E46 Contact a supplier or the parent company directly to get a quote or to find out aFind out all of the information about the CONSTMACH Concrete Plants & Crushers product: jaw crushing plant CJC60 highcapacity secondary primary jaw crusher CJC110 stationary highcapacity secondary impact crusher CPI 1412 stationary primary verticalshaft impact crusher VSI 900 CRJaw crushing plant CJC60 DirectIndustry

MK75J Primary Crushing Plant MK series crushing and screening station is a new type of integrated crushing and screening station continuously developed by our company in order to better meet the actual needs of customers This equipment is a largescale crushing product that is convenient for the installation and transition of the production lineKJ1251 Mobile Primary Crushing Plant Primary Crushing Plant is equipped with highefficiency jaw crusher and impact crusher, and millions of crushers have been installed worldwide since the end of the 20th century There are 8 types of jaw crushers and 4 types of impact crushers you can chooseJaw crushing plant KJ1251 DirectIndustry

2019年1月1日· Particle size distribution curves of recycled aggregates from building demolition concrete crushed by jaw and impact crushers The jaw crusher produced 60% of coarse aggregates in weight, whereas the impact crusher produced 49% coarse aggregates The proportion of particles finer than 015 mm is around 7–8% weight for both crushingFind out all of the information about the Fabo Crushing Screening & Concrete Plants product: jaw crushing and screening plant MCK110 MCK110 includes two stages of crushing process which is made by primary jaw crusher and Secondary impact crusher TECHNICAL SPECIFICATIONS: Bunker: 35 m3 Plant Dimensions (1st chassis):Jaw crushing and screening plant MCK110 DirectIndustry

Find out all of the information about the Fabo Crushing Screening & Concrete Plants product: stationary crushing and screening plant Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of plete primary and secondary jaw crushing plant in iran Jaw Crusher For Primary Crushing Jaw Crusher For Primary Crushing As we know in crushing plant there generally need a primary crusher and a secondary crusher in order to process the raw materials into required sizes Jaw crusher is the most commonly used primary crushingmplete mobile crushing plant

A freetouse drag and drop configurator that helps you design more productive and efficient plants through realtime insights Design and simulate a new crushing and screening plant in 3D or test how2016年2月26日· The term “primary crusher,” by definition, might embrace any type and size of crushing machine The term implies that at least two stages of crushing are involved, but in many cases the machine which performs the function of initial crusher is the only crusher in the plant The factors influencing the selection of a crusher for this servicePrimary Crushing 911 Metallurgist

Complette primary and secondary crushing plant rebuild in PRIMARY CRUSHER jaw crusher type: ALTERAC C1311, 1300 x 1100 mm (ALTERAC is today liming) feeder: complete primary and secondery jaw crushing plant Gyratory Crusher An Overview the secondary crushers are also designed on the principle of gyratory similar to jawThreeinone impact crusher mobile plant – APYL series Processing capacity: up to 200tph Configurations: 200Kw impact crusher + 1536 type return screen Maximum feeding: 350 medium soft rock Crushing materials: medium and soft rock and construction waste Applications: construction aggregate or road constructionMobile Crusher Plant CostSaving, High Mobility, Safety

DOVE Jaw Crushers are ideal rock crusher machines, highly efficient and economical for handling Primary and Secondary stone crushing applications of various ores and bulk materials with compressive strength below 320 MPaDOVE Crushers are supplied in Stationary complex plant configuration, or in Portable and Mobile configurationAs it turned out, designers are now adding secondary or pebble crushers to SAG circuits, on both greenfield and retrofit projects, to increase feed rate to the SAG mill In other words, crushing plants, from primary to quaternary circuits, are here to stay There are three main steps in designing a good crushing plant: process design, equipmentCrushing Plant Design and Layout Considerations 911 Metallurgist

Capacity: 120 t/h 150 t/h Motor power: 350 kW Opening height: 850 mm Introducing the Polygonmach PMCC2, a gamechanging mobile crushing and screening plant on wheels with an impressive production capacity of 120150It is the OneStop Shop for the entire range of Jaw Crushers, Vibrating Screens and Allied Plant Equipment 4432 HiPro Series Primary Jaw Crusher 3624 Rhino Series Primary Jaw CrusherStone Crushing Equipment and Rhino Series Primary Jaw Crusher

2023年2月28日· The two most common types are horizontal shaft impactors (HSI) and vertical shaft impactors (VSI) HSI crushers are designed for primary or secondary crushing applications and can produce a cubical product with high reduction ratios They work by using a spinning rotor with large hammers attached to the outer edgejaw crushing plant 5062 stationary primary Contact jaw crushing plant 5062 Opening height: 36, 38, 42, 48, 50 in The Jaw crusher is used as Primary and Secondary crushers for crushing all kinds of minerals and rocks with compressive strength less than 320 mpa There are two types of Jaw crusherPrimary crusher, Primary crushing and screening plant All