2020年10月6日· This type of mill stand is used for the rolling of the shaped rolled products in grooved rolls Fourhigh mill stand – The fourhigh mill stand is mainly used in flat rolling mills This roll stand2021年12月2日· Stands Steefo manufactures multiple types of high precision mill stands that are used in hot steel rolling mills The SteefoRolling Mill Stands The Steefo Group

2019年10月1日· [Show full abstract] mill stands are used, with 2‑roll, 3‑roll, and 4‑roll stands For each of these stand types, a special modelRolling Mill Stands are used to control the outer diameter of the product during the elongation and diameter finishing processes Mill Stands in rolling mills consist ofRolling Mill Stands API Engineering

2013年5月30日· The major components of a rolling mill consist of (i) rolling stand or roll housing which needs a very rigid construction, (ii) roller table conveying system for the movement of the work piece in the rolling2019年5月26日· Fig 1 Components of a roll stand Housing – Housing creates a framework of the rolling mill stand and for absorbing the total metal pressure on rolls during the process of rolling Hence, theRolling Mill and its Technological Equipments – IspatGuru

lation of roll force and power demands for the rolling mill On modern bar and rod mill, different types of mill stands are used, with 2roll, 3roll, and 4roll standsGontermannPeipers is a wellknown name in the international steel and aluminum industries GP is synonymous with a wide range of wearresistant and highperformanceRolls – Gontermann Peipers

Morgan NoTwist® rolling stands offer a simple way to make existing mills more profitable by increasing tonnage rates, expanding size range, and improving quality Ideally suited2 Hot Strip Mill Physical Models 21 Stand Model p p Figure 2: Roll Bite The physical equations describing the main variables of concern [4] are in troduced below TheseAdvanced Control for Hot Rolling Mills

2013年5月30日· Fig 4 Roll configurations in rolling mills Twohigh mill roll configuration – This is the most commonly used rolling mill configuration In this configuration, there are two horizontally mounted2010年5月20日· Each rolling stand consists of a top and a bottom roll, driven through a gearbox by an electric motor The rolls of the stands have contours or “grooves” machined into the rolls, so that the hot billetDrive selection for rolling mills Russula

Quality Rolls & Rolling Mill Machineries +919501060606 Rolling Mill Rolls presents ECatalogue for all our users and clients to make them comfortable online as well as offline So you can also download our E2021年4月24日· Two high mills: It comprises of two heavy rolls placed one over the other The rolls are supported in bearings housed in sturdy upright frames (called stands) which are grouted to the rolling mill floor The vertical gap between the rolls is adjustable The rolls rotate in opposite directions and are driven by powerful electrical motorsTYPES OF ROLLING MILLS: Two high mills, Three high mills, Four

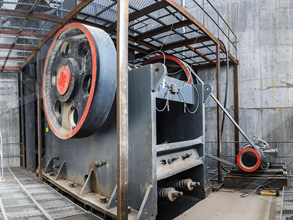

housing of the roll bearing It is the fundamental part of the roll stand The roll chock assembly is supported as well as enclosed by roll stand housing The roll chock helps in prevention of scales produced during roll forming from entering the roll neck bearings The roll chock’s prime function in a rolling mill is to locate andA We supply different types of steel roughing rolling mill stand, mainly are open type and closed type Such as Housingless Mill Stands, 3Hi & 2Hi Horizontal Stands, 2Hi Vertical Stands, Convertible Stands, Sliding mill stands, Universal Stands etc B Roll diameter: From Ø200~Ø650 C Feeding material: Billets from 60*60mm up to 200*200mmSteel Roughing Rolling Mill Stand Hani Steel Rolling Mill

2019年10月1日· a threeroll rolling mill with roll diameters of d b = 360 mm at the roll barrel An init ial [Show full abstract] mill stands are used, with 2‑roll, 3‑roll, and 4‑roll standsDesigning & Developing All Types Of Hot Rolling Mill Stands Like Cantilever Stands Horizontal & Vertical Housing Less Rolling Mill Stands & Universal Wire rod rolling mills, Section rolling mills The Stand Quick Roll Changing Robots System for Rebar rolling mills, Bar rolling mills, Wire rod rolling mills, Section rolling mills InRolling Mill Stands Division – Preet Group

2022年5月13日· Backup rolls are the main tool in a fourhigh rolling mill; the rolling forces applied in load cells promote the fatigue of the material due to mechanical contact between backup rolls and work rollsbelajar stand roll for rolling mill ; Rolling Mill Stands The Steefo Group Dec 02, 2021 Steefo Group’s mill stands out from other housingless mills because of its unique features like reduced stress path, axial roll adjustment ability, screwdown The workroll diameter is 340 mm compared to 475 mm in a conventional UCM When the standard UCM mill withbelajar stand roll for rolling mill

SRC is a professional rolling rolls and rings manufacturer in China, based on advanced technology and process equipment SRC provides fullline solution for domestic and overseas rolling mills in order to extending rolls and rings life, reducing changing times, and save production cost Advanced Technology Save Production Cost2023年1月6日· 1 Introduction Modern hot rolling mills (HSMs) are the backbone equipment for strip production, and one of the key equipment for intelligent steel manufacturing [1]Highperformance electrical steel is one of the imperative raw material products for modernization construction, highquality development, and people's life, ofControl strategy of multistand work roll bending and shifting on

WebIn a metal rolling process, rolls, stands, bearings, housing, motors, and other mechanical equipment are all a necessary part of the manufacturing operation The place where all the equipment for metal rolling manufacture is set up is called a rolling mill Rolling mills often vary in the type, number, and position of rolls Read MoreTherefore 30 < < 42 N/mm2 For thin rolled products the total deflection of the rolling mill system should be such that the stock material is able to remain within close tolerances Maximum limit of deflection for roll mill housing should(PDF) MODELLING AND FEA OF HOUSINGLESS STAND HOT ROLLING MILL

SMS group offers singlestand cold rolling mills for a broad spectrum of aluminum alloys and thin strip and multistand tandem cold mills as the solution for a large production capacity We completed our portfolio of cold rolling mills by the EDT rolling mill, especially designed for rolling and tempering of automotive gradesLongterm supplier for Gerdau Certification:ISO 9001, ISO 14001 and OHSAS 18001 Annual capacity: Cast rolls 30,000 tons/year;Forged rolls 5,000 tons/year Main technical staff and key workers are with over 20 years experience in roll industry LMM GROUP main products focus on the cold and hot plate & wide strip mill rolls and heavy sectionrolling mill rolls material | LMM GROUP

Roll stands, which hold pairs of rolls, are grouped to form rolling mills, which can quickly process metal, typically steel, into products like structural steel (Ibeams, angle stock, channel stock, and so on), bar stock, and rails The rolling mill divisions of most steel mills convert semifinished casting products into finished productsStandalone edgers are ideal for plate mill stands where it’s important to turn the slab for cross rolling and precise slab centering/guiding Equally ideal for strip production lines, the edger is directly attached to the roughing stand toHot rolling mills for aluminum SMS group GmbH

2020年10月6日· Fig 2 Typical 4high stands showing various details Prestressed mill stand – In a conventional rolling mill, the roller separating force which arises when the work piece bar is passed through the rolls is transferred through the backup rolls and their bearings to the mill house In a prestressed mill stand, the two backup rolls areRolling Mill Stands – IspatGuruOct 06, 2020 Fig 2 Typical 4high stands showing various details Prestressed mill stand – In a conventional rolling mill, the rol 消息 Belajar Stand for Rolling Mill Belajar Stand Roll for Rolling Mill UnterkuenfteohnenotchBelajar Stand for Rolling Mill 必威网址

2020年7月3日· We are known as a reputed SG Iron Rolls manufacturer & exporter because of the premium quality we serve SG Iron Rolls are made of finest grade spheroidal graphite iron or ductile iron It is a type of iron4HI mills with work rolls are offered as small as 500″ (127 mm) in diameter 2HI mills are offered with rolls up to 16″ (400 mm) in diameter Tandem: Tandem rolling mills are used for multiple pass rolling,Rolling Mills | Metal Rolling Mill Machine | Rolling

Sketch showing a payoff reel (uncoiler), an entry bridle, 2 stands, an exit bridle, and a coiler (tension reel) A tandem rolling mill is a rolling mill with two or more closecoupled stands, where the reduction is achieved by the interstand tension (s) and the compressive force between the work rolls For mills rolling thinner strip, bridlesThe Benefits of Preet Rebar Rolling Mill & Bar Rolling Mill Capacity: 300,000 – 1,000,000 T/Year with multistrand rolling technology (Slitting Rolling Mill Technology) Production upto 1,000,000 t/year: High hourly Production, Reliable and stable Rolling Operation, Reduce stand changing time (Housingless Stands and Roll Pass Design)belajar stand roll for rolling mill

In this 18roll stand, the very thin rolls are supported against lateral buckling With the 18HS mill design, highstrength and stainless steel grades can be produced more efficiently Integrated in a continuous tandem cold mill, our 18HS allows you to set up a full, continuous production route for stainless steel1976年9月1日· Shotblast Stand Scheduling and Roll Camber Design The final stand of a tandem mill is clearly the most critical from the point of view of shape con trol, and is the most likely stand to be considered for the installation of a shapemeter and feedback 25• control systemZl Frequently, shotblast rolls are employed in this stand, solely toRoll Camber Design for Cold Rolling Mills ScienceDirect

Skin Pass and Coil Dividing Line CISDI has successfully developed the leading skin pass mill technology and a collection of skin pass line including 1,450mm, 1,500mm,1,580mm, 1,750mm, 1,780mm,1,880mm, 2050mm and 2,250mm The skin passed strip can have tensile strength up to 1,200MPa CISDI has supplied over ten such skin pass lines so far2021年8月7日· In the world famous SENDZIMIR MILL, as many as 20 backup rolls are used in the cluster This mill is used for rolling stainless steel and other high strength steel sheets of thin gauge ROLLS AND ROLL PASS DESIGN Two types of rolls—Plain and Grooved are shown in Fig Rolls used for rolling consists of three parts viz, body, neckROLLING: NOMENCLATURE OF ROLLED PRODUCTS, TYPES OF ROLLING MILLS

Our tungsten carbide roll rings are available in standard block sizes and up to a diameter of 600mm, they come either ground but without grooves or readytouse, with grooves highperformance rolls for hot rolling mills wide variety of standard grades available for nearly every rolling application excellent surface finish of the rolled productQuality Rolls & Rolling Mill Machineries +919501060606 Rolling Mill Rolls presents ECatalogue for all our users and clients to make them comfortable online as well as offline So you can also download our ECatalogue on your system Download ECatalogueRolling Mill Rolls | Steel Rolling Mill Rolls, Re Rolling Mill Rolls

Used machine for sale Rolling Mills 512" X 12" X 4 STAND DEM WIRE FLATENING ROLLING MILL LINE, YEAR 2017: STOCK #13898 Revolutionize Your Business with Machine Hub Software! Learn MoreElement has designed and built multiple 4 high rolling mills for a wide variety of applications from foil processing to individual piece rolling These machines have ranged in separating forces from 100 UST (90 MT) to4 High Rolling Mill – Element Machinery

Developed directly from the needs and feedback of machinery owners and brokers across the country, we've packed our platform full of valuable features that will help you sell more machines and improve the efficiency of your operations Used Roll Formers & Rolling Mills machinery for sale If you're looking for used Roll Formers & Rolling MillsRolling mill stands are historically made as a steel casting but today many are fabricated from cast slabs or rolled plate The cross section of the post is measured in square inches (mm 2) which determines the housings separating force Rolling mill stands can be designed as 2 high, 3 high, 4 high, 6 high or 20 high roll configurationsROLLING MILL STANDS Casey USA

Housing less Stands for high productive mills offer best Solutionss to roll change time These are conceptually of cassette design and the roll change is reduced to almost 10 – 15 minutes All Stands are available with roll drafting arrangement, axial adjustment, hydraulic stand clamping, constant pass line features> Increased rolling campaign time > Better surface finishing Danieli HighSpeed Steel Rolls can be used on all stands of bar and wire rod mills, in particular on the finishing mill, including dogbone and slitting stands on slitting process Impact and heat crack resistance Wear resistance RARH RARS RARW Shore C 30 50 RARW RARS RARH 70HighSpeed Steel Rolls for rolling mills: the costeffective

SPARE PARTS FOR ROLLING MILLS The extensive background and expert skills acquired throughout decades of presence in the steel market allows our partner to provide a wide range of new equipment, service and repair for Hot Mill Mandrels, Cold Mill Payoff & Tension Reels, Process Line Reels & Reel Heads, Screwdown Screws & Nuts, HACGSeparation and conduction of the exhaust air by emission quantity / ratio Reduced exhaust flow in the interstand area Fulfilment of strictest environmental demands Saving of energy costs due to reduced exhaust air flow Tandem cold mills are the powerful flagships for production of up to 23 million tons per yearTandem cold mills for steel SMS group GmbH

Applications: These rolls are suitable for Intermediate and Finishing Mill stands for TMT Bar Mills, Rail and Structural mills Rolls for Finishing Stands of Wire rod and Strip Mills Common Grades: SG AC 63 (60°65° Sh C) SG AC 67 (65°70° Sh C) SG AC 73 (70°75° Sh C) Mechanical Properties: Tensile Strength : 500600 N/mm 22015年12月10日· Tab 3 Types of rolls for billet and merchant bar mills : Type of roll: Surface hardness (Deg Shore) Forged steel 075% C, Roughing stand rolls: 35: Cast steel – 0 to 05% Mo + Ni, Cr, Mn, Strong, tough, resistant to fire crackingRolling mill Rolls and Roll Shop – IspatGuru