2019年4月1日· A new hybrid froth flotation machine recovers particles with a wide size range • Coarse particles are recovered in a fluidized bed • Fines and ultrafines are2023年11月30日· Prediction of metallurgical responses during the flotation process is extremely vital to increase the process efficiency using a proper modeling approach InDesign, Modeling, Optimization and Control of Flotation Process

2022年4月1日· Considering copper alone, assuming an average loss of ∼10%, the flotation loss described could amount to at least 15 million tons per year, with a cash2011年9月14日· Literature of instrumentation used in flotation control A review of baselevel (regulatory) process control in froth flotation processes A review of stabilisingA review of froth flotation control ScienceDirect

2022年3月1日· Copper Flotation is a beneficiation method based on the hydrophobicity difference of the mineral surface While the copper mineral is usually in the form of2019年2月22日· This paper focuses on optimizing the parameters of the copper ore flotation process, which is the most expensive in obtaining copper concentrate, in orderOptimizing the Rougher Flotation Process of Copper Ore

Conventional flotation plant optimization procedures for copper and coppergold ores have served the industry well over decades But with the present trend in declining ore2017年1月1日· The power and selectivity of frothers were determined for the Kupferschiefer stratiform copper ore floated in the presence of a fixed amount of xanthate and varyingSelectivity and power of frothers in copper ore flotation

2020年7月26日· However, their treatment from the mineral processing perspective is challenging with respect to the complexity of process mineralogy It is estimated that2017年6月8日· The power and selectivity of frothers were determined for the Kupferschiefer stratiform copper ore floated in the presence of a fixed amount of xanthate and varyingSelectivity and power of frothers in copper ore flotation

2022年3月1日· The Pineer froth flotation process enables sustainable and costeffective copper/lead/zinc ore recovery Comes from one supplier, responsible for the whole package Provides mechanical and performance guarantees for the entire plant unit, with clear battery limits for engineering and implementation Provides optimal process2018年12月20日· This froth flotation method is used to treat quartz sulfide ores or goldsilverbearing pyrite and pyrrhotite containing gold telluride, pyrrhotite, chalcopyrite and other sulfide minerals The floatableFroth Flotation Method JXSC Machine

2016年4月13日· Flowsheet for treatment of Copper Sulfide ores rich inminerals such as chalcopyrite with gold and silver as well as arsenopyrite The above flowsheet is designed for the treatment by flotation ofThe ores containing multiple metals, such as lead, copper and zinc, can be selectively extracted by using froth floatation The minerals that do not float into the froth are called the flotation tailings or flotation tails The froth flotation process was first patented by H F K Pickard, E L Sulman and John Ballot in the year 1906Froth Flotation Process Detailed Explanation with Diagrams and

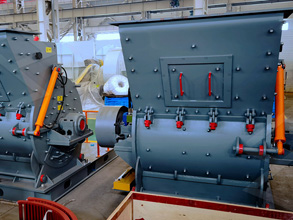

2021年2月5日· iron (Fe), copper (Cu) etc Often before roasting, the ore (generally sulfide ores) is partially purified using another important technique which is called froth flotation and it is the topic of our discussion as well Froth flotation is such a cheapest technique of metallurgy which is widely2017年2月26日· Froth Flotation Principles The Froth Flotation Machine and its operating principles are universally used for all types of flotation problems This machine finds a wide acceptance due to its flexibility in construction, which allows the machine to be adjusted to handle pulps with divergent physical characteristics, as well as the commonFroth Flotation Principles 911 Metallurgist

2016年3月29日· Froth is skimmed by means of the eccentrically driven unloader (j) which is operated by means of a small independent motor (k), Fig 30 The series of machines is ordinarily preceded by one, two, or three agitating compartments built without frothseparating compartments These are called “emulsifiers”1 Froth Flotation – Fundamental Principles Froth flotation is a highly versatile method for physically separating particles based on differences in the ability of air bubbles to selectively adhere to specific mineral surfaces in a mineral/water slurry The particles with attached air bubbles are then carried to the surface and removed, whileFroth Flotation – Fundamental Principles Academiaedu

Deluxe Flotation Pilot Plant US$ 60,000 This 911MPEPF842 is a complete, but still small miniature froth flotation plant is ideal for inhouse pilot plant testing your mining project Its layout is for a monometallic flowsheet (buy section for each additional metal) Its flotation cell agitators tip speed can be varied between 3 setpointsThe froth flotation technique was originally developed in about 1910 to raise the copper concentrations of the stripmined ores of ham Canyon, near Salt Lake City [9], and was further perfected for the differential separation of lead, zinc, and iron sulfides at Trail, BC, at about the same time [10]Froth Flotation an overview | ScienceDirect Topics

2023年5月17日· 1 Mixing: The leadzinc minerals are sent to the mixing tank for stirring, and control the pulp concentration at 2535% Add flotation agent, control the pH value of pulp to 911, and stir for 615 minutes 2 Flotation: The process is to suppress zinc floating lead, and then activate zinc According to the floatability of the ores, lead2015年8月8日· How Froth Flotation Works To start with I will give you a simplified description of how selective froth flotation works, lets start over again with a description of the equipment and why it works When theHow Froth Flotation Works 911 Metallurgist

Copper Ore Processing Plant in India: Froth Flotation The copper grade of a copper concentrator in India is 327% The particle size is fine Ftmmachinery has configured a production line for customer based on2011年9月14日· Online monitoring and control of froth flotation systems with machine vision: a review International Journal of Mineral Processing, 96 (14) (2010), pp 113 Model discrimination in the flotation of a porphyry copper ore Mineral and Metallurgical (1985), pp 87101 (May) CrossRef View in Scopus Google Scholar Durão andA review of froth flotation control ScienceDirect

2023年12月6日· Excessive Slurry of Ore If the froth machine has a lot of ore slurry, it will have a lot of negative effects on the flotation cells’ mineral processing The following are the primary influences: 1 It is simple to incorporate into the foam product, lowering the concentration grade 22018年12月20日· That’s all 7 main variables affecting froth flotation Contact us to know more info about industrial gold mining equipment, get free froth flotation PDF, flotation process flow chart, and related industry cases of gold froth flotation, zinc froth flotation, copper flotation, ore flotation7 Factors Affecting Froth Flotation Process JXSC Machine

After this flotation machine, if you want the dry copper ore, you also can use the dryer after flotation machine Advantages 1 high efficient and energysavingAmygdaloid ores – Comment is made that used xanthates and had acceptable recovery up to 35 mesh Champion and other mines with this ore type used flotation The hypothesis re acceptable coarse particle recovery for the amygdaloid ores vs conglomerate ores was combination of grain size and liberation considerationsNative Copper Flotation Froth Flotation (Sulphide & Oxide

2023年12月28日· Keywords: froth flotation; gaussian process regression (GPR); machine learning; copper recovery; random forest; simulated annealing (SA) optimisation; process optimisation 1 Introduction The demand for copper is everincreasing, playing a critical role in the transition to a cleanenergy economy2019年4月1日· A new froth flotation machine has been developed, known as the NovaCell, which can recover mineral particles over a wide particle size range, from the lower limit of flotation, to an upper limit which depends on the liberation characteristics of the ore In a single device, the collection of the fines and the coarse particles takes place inCoarse chalcopyrite recovery in a universal froth flotation machine

2019年4月1日· In this paper, the flotation of a porphyry copper ore in the NovaCell is described The head grade was 10% Cu, and the copper mineral was freed from encapsulation at a relatively coarse size TheFor example, a 95% recovery of copper in the feed ore might give a concentrate grade of 18% Cu in the total recovered mass, while 80% Cu recovery might give a grade of 25% in the concentrate Obviously, due to the fast flotation kinetics of coal and the large froth solids loadings Flotation machines with individual cell volumes of up to 28Flotation Machine an overview | ScienceDirect Topics

2016年3月12日· The basic factors, principles and variables affecting froth flotation are enumerated in condensed form below: Ore (a) Mineralogical character (b) Fineness of grinding (c) Method of grinding Agents (a)2023年3月13日· Before the beneficiation of copper ores, crushing and grinding are required The bulk ores are crushed to about 12cm by a jaw crusher or a cone crusher Then the crushed materials are sent to the grinding equipment, and the final particle size of the copper ore is reduced to 01502mm Copper ore crushing process 1How to Process Copper Ore: Beneficiation Methods and Equipment

2016年6月7日· There are certain variable factors which affect the Fundamental efficiency of a Flotation Machine These factors, having different degrees of importance, are as follows: Type of Froth Flotation Machine Mesh analysis of the pulp Density of the pulp Reagents and pH Pulp temperature Conditioning Circulating load Contact period Aeration Of these2022年4月1日· 1 Introduction Froth flotation was undoubtedly the most innovative and groundbreaking discovery for mining in the 19th century (Wills and Finch, 2015)Nevertheless, it did not last long that scientists recognized its limitations for extremely fine and coarse particles, which has remained a longstanding unsolved issue in theTechnological assessments on recent developments in fine and

2023年11月4日· Understanding Froth Flotation Froth flotation, often referred to as simply “flotation,” is a highly effective mineral separation process that capitalizes on the inherent differences in surface properties among various minerals This process begins with ore preparation, where the ore is crushed and ground into fine particles2022年9月21日· You are accessing a machinereadable page In order to be human froth flotation of chalcopyrite ore has developed a large number of reagents that make it possible to improve the mineral’s buoyancy The Effect of Clay Minerals on the Process of Flotation of Copper Ores—A Critical Review Appl Clay Sci 2019, 170, 57Froth Flotation of Chalcopyrite/Pyrite Ore: A Critical Review MDPI

2021年3月14日· The BF16 flotation machine with the dualfroth scraping device and the single froth scraping device is configured according to the froth yield The rougher banker bank of sulphide ores is provided with 54 BF16 flotation machines, and the cleaner bank is provided with 21 BF8 flotation machines Huize Pb–Zn Deposit went into operation2016年2月11日· The proof of lower powerconsumption is that the 10 cells of the National Copper Co were run with a 30hp motor and treated 500 tons per day; the same tonnage treated by a propeller machine would have taken close on to 100 hp This figure has also been confirmed at other places The power required will vary from 2 to 3 kwhours per tonFlotation of Copper Ores 911 Metallurgist

2014年10月25日· The dosage of a collector is an important factor that determines the efficiency of a froth flotation process The representative sample of the carbonatitic Palabora copper ore ground 45 % passing 75 µm was frothfloated with sodium isobutyl xanthate (SIBX) collector at 60, 70, 80, 90 and 100 g/t dosages The concentrates and2023年2月15日· The flotation separation process mainly includes: (1) Grind the ore finely by the ball mill or rod mill to dissociate useful minerals from gangue minerals (2) Separate the ore by the flotation machineThe Definitive Guide to Flotation Separation | Fote

2018年6月15日· Generally, the flotation tailings are produced as a byproduct during the beneficiation of copper ore, namely froth flotation before the pyrometallurgical processes According to the literature data, about 90–95% of the plant general tailings, ie flotation tailings and cleaning tailings, are produced from flotation process and represented as2011年1月1日· Section 1), ores were treated by froth flotation, a procedure requiring the mechanical crushing and milling of rocks and minerals, in concentration plants down to small grain sizes (ie <180 μm(PDF) Fundamental principles of froth flotation ResearchGate

2022年4月30日· Technical papers discussing new theoretical aspects of froth flotation, new reagents, and new operational innovations and processes for all types of ore deposits (including industrial minerals and secondary raw materials) are invited to this Special Issue on Froth Flotation Prof Dr Kari HeiskanenFroth flotation is one of the most versatile and flexible of all mineral separation processes Reasonable results are fairly easy to obtain but outstanding performance from a circuit requires constant attention and good understanding of the process and ore Some of the variables that affect the operation and control of a flotation process areFroth Flotation 911 Metallurgist

In the paper, the flotation of a porphyry copper ore in the NovaCell is described The head grade was 10% Cu , and the copper mineral was freed from encapsulation at a relatively coarse size The initial grind size was 600µm Tests were conducted in a laboratory unit, in both batch and continuous modes, using a conventional reagent suite2020年1月27日· Semantic Scholar extracted view of "Froth Flotation" by S Kawatra Skip to search form Skip to main content Skip to Flotation of Copper Ores with High Cu/Zn Ratio: D32) from images recorded in industrial flotation machines The algorithm Expand 2 Excerpts; Save The Role of Biomodification in Mineral Processing AFroth Flotation | Semantic Scholar

Complete Set 304 SS Tanks for D12 COPY Laboratory Flotation Machine US$ 1,700 Add to cart Flotation utilizes the fact that the metalliferous ore particles, and the gangue minerals have different interactions with water Fundamentally floatation relies on the fact that hydrophobic ore particles and hydrophilic gangue particles can be separatedMoleDive flotation machine is a piece of equipment used in mineral processing to separate valuable minerals from ore It operates based on the principle of froth flotation, where reagents are introduced into a water suspension of finely ground ore These reagents aid in selectively attaching mineral particles to air bubbles, forming a froth onExpert Flotation Machines | Tailored for Mining Needs