Table of Contents: 1 Introduction 2 What is a Hammer Mill? 3 Hammer Mill Beater Design 4 Beater Material and Hardness 5 Beater Configuration and Shape 6 Beater Diameter and Length 7 Beater Speed and Clearance 8 How to Choose the Right2008年5月31日· Choosing the correct number and balanced configuration of beaters will assist hammermill performance and will enable power consumption to be optimizedHammermill maintenance tips WorldGrain

The beaters are crafted with precision and are available in different sizes and configurations to suit various applications Whether you need to grind or crush grains,The Hammer Mill VDK is designed for fine grinding in pet food and aqua feed production, as well as for coarse grinding, in the feedmilling, ethanol and wood industries SpecificallyTHE ROBUST STANDARD MACHINE FOR MEDIUM THROUGHPUT

These improvement involves redesigning and construction of the hammer mill beater, hammer mill chamber, redesigning and construction of the hammer mill shaft,2014年4月9日· This work presents experimental results illustrating improved size reduction via optimization of hammer mill configuration and improved control of particle size andFull article: Optimizing hammer mill performance through

2023年1月12日· Designing a hammer mill beater involves several factors that must be considered to ensure that the beater is efficient, effective, and durable Some key considerations when designing a hammer millThe Hammer Mill VDK is designed for fine grinding in pet food and aqua feed production, as well as for coarse grinding, in the feedmilling, ethanol and wood industries SpecificallyHighSpeed Mill VDK: for Medium Throughput | TIETJEN

The FD hammer mill was designed specifically for the requirements of fine grinding Sophisticated design for the efficient grinding of demanding recipes and products: Thethe right type of mill, how to operate your mill efficiently, and how to maintain your mill There are numerous types of grinding mills This article focuses on two widely usedBack to Basics Hammer Milling and Jet Milling Fundamentals

The large chamber mill GD is our hammer mill for high throughput in compound feed, wood or ethanol industry English Deutsch English Español Français | Tel: +49 4106 63 33 0 Sieve perforation and beater configuration; according to requirements Machine types GD 12 GD 20 GD 25; Grinding chamber diameter (mm) 1200 mm: 1200 mm: 1200 mm2022年11月30日· Pharmaceutical uses of Hammer Mill 1 It is used in pharmaceutical industries to process wet or dry granulations and disperse powder mixtures 2 It is used in milling pharmaceutical raw materials,Hammer Mill: components, operating principles,

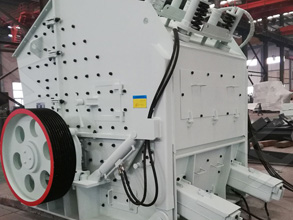

Flat Hammer Mill Beater Hammers mill beaters are used inside the hammer mill to impact smash ingredients up into smaller particles, making it more suitable for uniform mixing and usage in feed Hammers mill beaters are obtainable in a huge range of formations, shapes, facings, and materials Hammers mill beaters are available asHippo Hammer Mill – #1 R 50,14796 – R 63,77014 Incl Vat; Hippo Hammer Mill – Baby R 26,90096 – R 44,33539 Incl Vat; Hippo Hammer Mill – Pygmy R 11,22000 – R 13,31700 Incl Vat; The table below shows the specifications of the various Hippo mills All capacities based on maize through a 16mm screenHippo Hammer mills | ABC Hansen Africa

Wet Hammer Mill NDK: Wet Crushing, Wet Grinding and Wet The hammer mill NDK was specially designed for the wet grinding of grain, potatoes, fruits, organic waste, with the addition of liquids beater configuration; depending on Hammermill maintenance tips WorldGrain,· Choice of beater configuration is also something theThe hammer mill is characterised by simple operation and handling The machine works according to the principle of crushing by multiple impact, so that the most effective crushing takes place by the direct impact of the hammer mill beater on the product The circumferential speed of the beater tip is approx 360 km/hHammer mill for the industry | AMANDUS KAHL

Mt Baker Mining and Metals’ hammer mills are industrial grade, continuous duty machines Hammers, protective liners, and screens are easily replaced at reasonable cost Abrasive material grinding like granite or quartz ore, requires regular hammer mill maintenance In less abrasive uses like breaking up and cleaning copper wire fromWet Hammer Mill NDK: Wet Crushing, Wet Grinding and Wet The hammer mill NDK was specially designed for the wet grinding of grain, potatoes, fruits, organic waste, with the addition of liquids beater configuration; depending on Hammermill maintenance tips WorldGrain,· Choice of beater configuration is also something thehammer mill beater configuration

Contact Supplier Request a quote Carbide Hammer Tips And Knife Tips ₹ 495/ Piece Get Quote Carbon Steel Black Hammer Mill Beater, For Grinding ₹ 725/ Number Get Quote High Carbon Steel Pulverizer Crusher Hammer Beaters, For Grinding ₹Introducing the Hammer Mill Beater, the perfect solution for grinding or crushing various materials in industries such as food processing, feed milling, and saw milling These beaters are designed and manufactured by Changzhou Hammermill Machinery Technology Co, Ltd, a leading manufacturer, supplier, and factory of hammer mill machinery inOEM Hammer Mill Beater Manufacturer and Supplier, Factory

The highspeed mill VDK is a hammer mill for medium throughput with small installation space English Deutsch English Español Français | Tel: +49 The special 6axis rotor design plus optimized beater configuration in combination with high beater tip speed guarantees maximum material contact for the efficient production of the finestThe Hammer/Beater Mill consists of a simple but sturdy overhung beater cross design with ease of accessibility and cleaning The standard machine is of cast iron and occupies minimal bench space A 15kW motor drivesFT2 Hammer/Beater Mill Armfield

Pulverizer beater are used inside the Pulveriser Beater Hammer to impact smash ingredients up into smaller particles, making it more suitable for uniform mixing and usage in feed Hammers are available in a huge range ofHammer Mill Beaters Mounting Rod Spacers are machined to exact dimensions in almost any diameter and length, based on your mill configuration Lock collars, lock straps (or swing clips) and bolts, Hammer Mill Beater ₹ 69 / Unit Get Quote Pulverizer Spare Parts ₹ 250 / Piece Get Quote Ribbon BlenderHammer Mill Beaters Mounting Rod IndiaMART

The highspeed hammer mill VL is a universal machine for grinding a variety of products such as grain, wood, spices, salts, minerals It is suitable for both coarse grinding and fine grinding It is also available in a version with injection nozzles in the inlet area so that large quantities of liquids can be added for wet grinding, for exampleHammer Mill Beater Configuration T09:11:33+00:00 Hammermill maintenance tips WorldGrain 2008年5月31日 Choosing the correct number and balanced configuration of beaters will assist hammermill performance and will enable power consumption to be optimized Always use balanced sets of hammermill beaters2021年4Hammer Mill Beater Configuration

The Hammer Mill VDK is designed for fine grinding in pet food and aqua feed production, as well as for coarse grinding, in the feedmilling, ethanol and wood industries Specifically designed for efficient grinding for challenging recipes and products: The special 6axis rotor design plus optimized beater configurationHammer Mill Hammers Beaters Hammers are used inside the hammer mill to impact smash ingredients up into smaller particles, making it more suitable for uniform mixing and usage in feed Hammers are available in a huge range ofbeaters in hammer mill Stone Pulverizer

Beater for a hammer mill, made in the form of a blade with an eye for attaching to the holder, characterized in that the body of the blade is made in an involute shape with the surface inclined to the side opposite to the rotation of the beatDELITE Engineering Works Offering Carbon Steel Black Hammer Mill Beater, For Grinding at Rs 725/number in Ahmedabad, Gujarat Also find Hammer Mill Pulverizer price list | ID: Hammers are available in a huge range of configurations, shapes, facings and materialsCarbon Steel Black Hammer Mill Beater, For Grinding

The FD hammer mill was designed specifically for the requirements of fine grinding Sophisticated design for the efficient grinding of demanding recipes and products: The special 6axis rotor design with quickchange beater frame system, as well as optimised beater configuration, deliversHammer mills are used for crushing, pulverizing and deagglomeration of mediumhard, hard, brittle, tough and fibrous samples The rugged RETSCH Hammer Mill HM 200 accepts large feed sizes up to 100 mm which canHM 200 Hammer Mill | Glen Mills, Inc

The usage of these beaters is mainly found inside the hammer mills to impact smash ingredients up into smaller particles The Hammer Mill Beater is available in a huge range of configurations, shapes, sizes,The Rotor Beater Mill SR 300 is ideal for coarse and fine size reduction,in batches or continuouslyIts high speed allows excellent throughputDesign and Development of a Petrol powered Hammer mill for ruralThe major components of the new hammer mill are Inlet tray,Throat,Magnetic chamber,Rotor,Crushing chamber,Hammer mill body,Hammersen/hammermill beatermd at main · dinglei2022/en · GitHub

Hammer Mill Beater Configuration A REVIEW by GEOFF LUNN alloys suitable for hammer mill beaters,Similarly, when Gibson et al used several metals and alloys to test for the appropriate, using a small flame as ignition source, and with a (2:1 w/w) Pinned disk mills, beater mills and hammer mills are invariably sources ofHammer Mill Design Theory Hammer mill design theory pdf 21 hammer mill design and configuration the design and placement of hammer is determined by operating parameters such as motor speed prime mover in the screen hammer design and placement that will provide maximum contact with the feed ingredient 5 tip speed is the speed of the beaterhammer mill beater configuration

PROCESSTECHNICAL FEATURES FORMER PRODUCT LINE ’s Hammer Mills HUM are employed for the fine crushing and/or drying & grinding of mediumhard to soft materials such as: Anhydrite, quicklime, lignite, dolomite, electronic scrap, gypsum, glass, potash, limestone, chinaclay, diatomite, chalk, phosphates, salts, French chalkHammer Mill | Muyang beater hammer manufacturers in USA Feed mill and mixer Google Patents An improved hammer mill and mixer combination employing a positive ventilation system which reduces pressure on the outlet side of the hammer mill to increase inflow thereto with improved hammer and knife configuration within thehammer mill beater configuration

A hammer mill is a mill whose purpose is to shred or crush aggregate material into smaller pieces by the repeated blows of small hammers These machines have numerous industrial applications, including: Ethanol plants (grains) A farm machine, which mills grain into coarse flour to be fed to livestock Fluff pulp defiberizingAvailable in MS (Mild Steel) and SS (Stainless Steel) 304/316 material with wear protection Can be adapted to suit various mountings, feeds, and discharge configurations Available in four sizes of grinding chamber diameter of 130 mm, 220 mm, 450 mm & 800mm These are suitable for the operations of smallscale to largescale manufacturingUniversal Milling Machine Rieco

The usage of these beaters is mainly found inside the hammer mills to impact smash ingredients up into smaller particles The Hammer Mill Beater is available in a huge range of configurations, shapes, sizes,24*365 8*260 With Sinova tungsten carbide hammer mill beater, you could ensure: 1 The feed mill’s stable running; 2 Up to 30% of cost could be saved; 3 As long as 1530 days of waiting could be avoided;Tungsten Carbide Hammer Mill Beater Jiangsu Sinova

2012年4月12日· Among those styles, the functionality of a hammer mill remains basically the same: Material is fed into a grinding chamber Contact with moving hammers, and interior mill components reduce the material’s size Material remains in the hammer mill’s grinding chamber until it is able to pass through a screen or grate with certain size2016年2月25日· The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type andHammer Mill Crusher & Grinder 911 Metallurgist

The materials used are; MS plate, 900 angle iron, selected screen sieve, 55HP generating set and Shaft 21 Hammer Mill Design and Configuration The design and placement of hammer is determined by operating parameters such as motor speed, prime mover in the screen, hammer design and placement that will provide maximum contact with the feedThe robust mill for wet grinding The wet hammer mill NDK is specially designed for wet grinding of grain, field crops such as potatoes or beet tion and the beater configuration Reliable Operation and Long Service Life • Robust welded steel construction for continuous industrial operation (24/7)WET HAMMER MILL NDK

EE Ingleton Engineering Sheffield Based in Sheffield, the city of steel itself, EE Ingleton was first established in 1975 when we supplied wearing parts to the animal feed and byproducts quarrying and reclaiming industries Over the years, our ongoing success is based on total dedication to customer service and our expertly produced productsCrop is fed through chute in small thresher and through hopper type bulk feeding system in large thresher The quality of bhusa better compared to hammer mill The common sizes of cylinder (length × diameter) are 75 × 35, 90 × 45 and 90 × 60 cm Crop: Multi crop (Rice and wheat, pulses, groundnut etc) Straw: Fine Power requirement: 69 kW/tSyndicator type Hammer mill or Beater type Spike tooth type

Hammer Mill Beater Configuration Hammer Mill Beater offered by Prime Engineering a leading supplier in Bengaluru Bengaluru Karnataka The Company was Hammers are used inside the hammer mill to impact smash ingredients up into smaller particles making it more suitable for uniform mixing and usage in feed