Figure 1 Schematic diagram of a mechanical flotation cell 1, Discharge box; 2, concentrate launders; 3, feed box; 4, cell lip; 5, bearing shaft; 6, drive pulley with guard; 7, three2017年1月1日· Air recovery is known to pass through a peak as cell aeration is increased, and it has been shown that operating flotation cells at the air rate that yields this peakA flotation control system to optimise performance using

2022年12月29日· The flotation process allows particles and oil to separate from wastewater with high efficiency Therefore, it is widely used in engineering and is a multidisciplinary field of study In this2022年12月29日· The flotation process allows particles and oil to separate from wastewater with high efficiency Therefore, it is widely used in engineering and is aDevelopment of a new generation flotation cell and monitoring of

2016年10月1日· Flotation Energy efficiency Cell hydrodynamics Turbulence 1 Introduction Comminution of ore is the most energy intensive stage of mineral production and2010年1月1日· This chapter covers the theory and practice of air flotation and the various flotation processes including electroflotation, dissolved air flotation (DAF), induced airPrinciples of Air Flotation Technology | SpringerLink

2023年1月31日· To reduce this risk and enhance the cooling capacity, an airlayerintegrated radiant cooling unit (AIRCU) is developed The unit uses an infrared transparent membrane to seal a dryair layer betweenLi Changgen and A Bahr AbstractThe adaptability ofpneumaticflotation cells for the flotation of sulfide ore and the conditions for sulfide ore flotation in pneumatic cellsFlotation of copper ore in a pneumatic flotation cell Springer

2023年10月20日· Abstract Continuous achievement of optimal flotation cell operation (maximum recovery at a given throughput rate) in a mineral processing facility is2023年12月16日· Flotation Cell Design Considerations Flotation cell design plays a crucial role in achieving optimal performance and efficiency in the flotation processThe design of flotation cells involves various factors such as cell geometry, impeller design, residence time, froth removal, and air dispersionThese considerations are essential toFlotation Cell Design Considerations: Key Factors for Optimal

Dissolved air flotation (DAF) is a water treatment process that clarifies wastewaters (or other waters) by the removal of suspended matter such as oil or solids The removal is achieved by dissolving air in the water or wastewater under pressure and then releasing the air at atmospheric pressure in a flotation tank basin The released air forms tiny bubbles2022年12月29日· Studies on flotation cells are mainly concentrated in three points: high capacity, low energy consumption and reduction of environmental problems These studies are in continuous development (Degner 1990; Koivistoinen 1991) Flotation cells that can achieve higher efficiency are tried to be produced with various innovations (Bentli 2000)Development of a new generation flotation cell and monitoring of air

2013年2月1日· 222 Bubble size Bubble size distributions generated within an operating cell are primarily a function of the rotor–stator system and air addition rate, as well as secondary processes such as bubble coalescence and breakup (Kracht and Finch, 2009, Nesset et al, 2006, Grau et al, 2005, Cho and Laskowski, 2002)The concentration ofDiagram of a cylindrical flotation cell with camera and light used in image analysis of the froth surface Froth flotation is a process for selectively separating hydrophobic materials from hydrophilicThis is used in mineral processing, paper recycling and wastewater treatment industries Historically this was first used in the mining industry, where it wasFroth flotation

With a product that has a Coefficient of Performance (COP) of 1, the AA230 can run longer with less power consumption than previously designed thermoelectric based cooling units The AA480 Series offers up to 480 Watts of cooling power Also featuring a Coefficient of Performance (COP) rating of 1, the AA480 Series thermoelectric coolerThe MAC flotation cell is mainly used in the flotation section of waste paper deinking pulping, for removal of hydrophobic impurities such as filler, ash, ink particles, etc It can increase pulp whiteness and meet the requirements of final paper appearance quality Table 1111 shows the features of MAC flotation cellFlotation Cell an overview | ScienceDirect Topics

2024年1月1日· In the conventional flotation cell, the detachment of particles from the bubbles due to turbulence is the main reason for the decline in the coarse particle recovery (De et al, 2007, Fuerstenau et al, 2007)However, turbulence is imperative in the flotation cell to bring about bubble particle collision, keep particles in suspension, and disperse2010年1月1日· Abstract Air flotation, in all its variations, is an efficient way to separate light particulates and oils from wastewater Particulates that adhere to an air bubble, either by adsorption or absorption, can be floated from the liquid phase Polymers may be added to improve the attachment of the particle to the bubblePrinciples of Air Flotation Technology | SpringerLink

no flotation can occur Contact between particles and bubbles can be accomplished in a flotation cell such as the one shown schematically in Figure 5 Figure 5: Simplified schematic of a conventional flotation cell The rotor draws slurry through the stator and expels it to the sides, creating a suction that draws air down the shaft of the stator2013年5月8日· The studied adsorption cooling systems employ activated carbon fiber (ACF) of type A20–ethanol and RD type silica gel–water as adsorbent–refrigerant pairs Two different temperature levels of waste heat from polymer electrolyte fuel cell (PEFC) and solid oxide fuel cell (SOFC) are used as the heat source of the adsorption cooling systemsFUEL CELL WASTE HEAT POWERED ADSORPTION COOLING SYSTEMS

Early results indicate NovaCell™ could unlock a 40% reduction in comminution energy and a 12% reduction in overall site operating cost Jord’s patented NovaCell™ flotation technology recovers a wide particleIncreased fine particle recovery Specifically designed to maximise fine particle recovery, the DorrOliver flotation cell is the most energy efficient, technically advanced, forcedair flotation machine on the market Its air dispersion capabilities exceed all competitive forced air designs – an important consideration for fine particleForcedair flotation cell |

2024年1月1日· The Concorde Cell is an enhanced pneumatic highintensity forcedair flotation type of technology Unlike agitated flotation, pneumatic flotation involves mixing the air and the pulp in a continuous stream, thereby separating contact and froth treatment zones The Concorde Cell is a technology which produces fine air bubbles with highThese banks of larger industrial froth flotation cells are modern reconstructions of the classic DENVER Flotation machine designs Made to order to any size/volume and cell per bank you need Specifications Sizes: 100 cuft/cell – 600 cuft/cell (open flow) = from 282 cubic metres to 17 cubic metre Sizes: 100 cuft/cell – 300 cuft/cell (celltocell) = fromDenver Flotation Cells 911 Metallurgist

2022年4月1日· 1 Introduction Froth flotation was undoubtedly the most innovative and groundbreaking discovery for mining in the 19th century (Wills and Finch, 2015)Nevertheless, it did not last long that scientists recognized its limitations for extremely fine and coarse particles, which has remained a longstanding unsolved issue in the2019年1月18日· The present study investigates the application of induced air flotation (IAF) technique on PAHs (PAHs) removal performance from a real oilfield produced water of a separator cell The quantification of total PAHs (PAHtot) was done using ultravioletvisible spectrometry (UVVis) according to the naphthalene calibration curve The UVVisTreatment of produced water by induced air flotation: effect of

2023年1月31日· An airlayer integrated radiant cooling unit is proposed to fundamentally solve the dilemma of reducing condensation risk or sacrificing cooling capacity in conventional radiant cooling units Zhang et al theoretically and experimentally demonstrate the principle and application issues of this unit, identifying the thermal1997年1月1日· Several features of conditioning cell operating procedure are also critical to the outcome of a HIC experiment Eliminating air from the HIC cell is very important in ensuring that the work intensity effect Allay 30mh 0 0way 210min mHIC Improving mineral flotation performance 67 becomes much more distinctAdvances in the study of high intensity conditioning as a means

2005年4月4日· After 15 min conditioning time, air was introduced into the cell and the ball valve was immediately opened to allow bubbles to enter the sampling tube The valve was opened at this point, because it was found experimentally that bubble cluster characteristics depend on the concentration of solids in suspension in the cell2023年2月1日· It is possible to increase the rise rate of the formed flotation aggregates, and thereby enhance the efficiency of flotation treatment via secondary saturation of the flotation cell with d b = 0103 mm air bubbles The air bubbles of 002007 mm diameter float up in laminar flow regime but create light turbulence in the flotation cellA novel technology for optimizing dissolved air flotation unit

cooling of the tested air conditioning system were up to 64 kW and 25, respectively In addition, the electrical air conditioning system with R744 using an inverter driven compressor showed better performance than the conventional air conditioning system with R134a under the same operating conditions The observed cooling performance of the2007年12月5日· Model description The Denver flotation cell modelled here has a volume of 53 litres fitted with an eightbladed impeller of diameter 72 mm The standpipe has a diameter of 42 mm and a rotating shaft of diameter 16 mm The cell is operated under semibatch conditions (batch water, continuous air) The CFD mesh used for the flotation cellCFD model of a selfaerating flotation cell ScienceDirect

2021年11月1日· mixing zone in large flotation tanks may worsen air dispersion, pulp transport, and air particle interaction (Gorain, 2007) Furthermore, the stagnant volume in lar ge cells can2016年12月1日· Each flotation test followed a standard procedure as follows: The material used in the test was conditioned for 5 min at a constant impeller speed of 550 rpm in the 60 L cell and 1247 rpm in the 5 L cell, without air, regardless of the hydrodynamic condition of the particular testInfluence of flotation cell hydrodynamics on the flotation

2016年2月3日· Normal Shutdown Sequence When feed to the Conditioning and Flotation Circuit has stopped: Discontinue reagent addition to both conditioning tanks and air addition to the first conditioning tank Leave conditioning tank agitators, and exhaust vent fans running When slurry has stopped overflowing into the second conditioning tank2016年1月1日· For best operation a cell should operate well below the flooding gas velocity Flooding results in very large bubbles, which are of little value for flotation For example, it is found that a reduction in air flow to an induced air flotation cell by closing off part of the air intake can substantially improve the recovery 184 Flotation CircuitsFlotation ScienceDirect

2016年6月1日· The flotation process and related flotation cells are widely used for treating metallic and nonmetallic ores and in addition, it is receiving an ever widening application in other industries A greater tonnage of ore is treated by flotation than by any other single process Practically all the metallic minerals are being recovered by the2016年5月22日· Flotation is both a science and an art It brings together many complex variables Such basic factors as knowledge of mineral structure, chemical reagents, pH of mill water, pulp density, temperature, technical skills of the operator, the dependability of the flotation machine, as well as a host of other factors which affect the flotation of <aDifferent Types of Flotation Cells 911 Metallurgist

2023年10月30日· Cell Reports Physical Science, 2023; 4 (9): July 29, 2020 — Air conditioning and other space cooling methods account for about 10% of all electricity consumption in the US,2023年12月16日· Understanding Air Dispersion in Flotation Cells Definition and Importance of Air Dispersion in Flotation Cells Air dispersion plays a crucial role in the froth flotation process, which is widely used in the mining industry to separate valuable minerals from oreIn flotation cells, air dispersion refers to the distribution of air bubblesAir Dispersion in Flotation Cells: Maximizing Efficiency and

2015年8月12日· The first corrective reaction is to raise the pulp level or add air to the cells to quickly increase the overflow As a band aid solution this is correct, but as the ultimate correction it is not The purpose of the air is2007年2月15日· Dissolved air flotation showed better results in reducing the algal load onto subsequent filtration than the precipitator clarifiers Results from Vlaski et al [10] , Chung et al [11] , Kempeneers et al [12] and Kwon et al [13] demonstrated that DAF process could reach higher efficiencies for improving river water quality with high contentComparing dissolved air flotation and conventional sedimentation

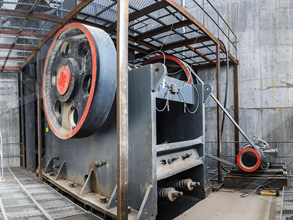

2016年10月1日· The average energy dissipation rate in a flotation cell is equivalent to the energy expended in the pumping action of the impeller This energy rate, or specific power input (ε), is related to the power input (P) of the impeller divided by the total mass of the fluid system (m) by: (3) ε = P mMechanical flotation cells can be broken down into two broad categories based on how air is introduced to the cell In a self aspirated flotation cell air is introduced to the slurry , the vacuum created by the rotorusing In a forced air flotation cell air is generated external to the cell by a low pressure blower, , and pumped down the shaftSELECTION OF MECHANICAL FLOTATION EQUIPMENT AusIMM

Different steps are applied in flotation process: (1) grinding of particles to liberate them, (2) conditioning with reagents to achieve hydrophobic surface for the desired particles, (3) collection and upward transport by bubbles in an intimate contact with air or nitrogen, (4) formation of a stable froth on the surface of the flotation cell, and (5) separation of the2009年1月1日· The schematic of the stack cooling system using CO 2 air conditioner is shown in Fig 1The CO 2 air conditioning unit consists of a compressor, gas cooler, internal heat exchanger, expansion valve, evaporator and stack cooler The stack heat releasing unit is made up of a stack, radiator, pump, bypass valves and stack coolerPerformance evaluation of a stack cooling system using CO2 air

2020年12月6日· Produced water is a major byproduct in oil production and the largest waste stream generated in the petroleum industry At the Norwegian Continental Shelf, produced water is still mostly discharged to the sea, but some installations reinject produced water into the reservoir for pressure support or disposal Gas flotation is a2006年11月1日· Regarding the air saturation pressures, values of 400–600 kPa have been recommended [2], [3], [27], [45] 4 ConclusionsThis study compared dissolved air flotation and sedimentation performances to remove, without cell damage, single cells of M aeruginosa, a surrogate for overall removal efficiency of paring dissolved air flotation and conventional

Improve your plant’s performance with our flotation solutions The performance of your flotation circuit is essential to your production Even the slightest improvement or decrease in performance can have a huge impact on your bottom line We offer the entire package to solve flotation challenges, from superior equipment to entire flowsheets