The separation of phosphate rock from impurities and nonphosphate materials for use in fertilizer manufacture consists of beneficiation, drying or calcining at some operations,In the ball mill the rock phosphate is crushed about 96% is passing through 100 mesh, which requirement of the process Fine rock phosphate particles are collected throughSSP Manufacturing Process – Jobson Enterprises

2021年10月28日· The continuous crushing of phosphate rock to meet particle size specifications is essential for efficient downstream processing Yet mills are more2022年9月15日· A Comparison of Mills Used for Phosphate Rock Grinding by Curt Snyder | Sep 15, 2022 | Airswept Mill Products & Solutions There are similarities andA Comparison of Mills Used for Phosphate Rock Grinding

Mill selection is primarily based on an ability to continuously crush hard, friable phosphate rock to specification This Fig 1: Ring roller mill Source: Bradley Pulverizer needs to beA laboratory study was conducted to identify the effects of milling under various conditions, including use of water and potassium as milling lubricants, on several physicochemicalEffect of Ball Milling under Various Conditions on Several

2023年7月24日· Biochar was produced at 600 °C and modified with humic acid (1:10 w/v ratio) and rock phosphate (05:1 w/w ratio) Additionally, produced biochar, as well asThe phosphate ore processing can be divided into three stages: crushing—separation—concentrate dehydration 1 Ore crushing process includesPhosphate Rock Beneficiation Process JXSC Machinery

Phosphate Rock mining process, how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design read moreBall Mill, Ayr Ontario; Cement Mills Manufacturer; Coal Crusher Machine Pour Exploiter L Or En Afrique; Crush Plant 350 Tons Crushing Machine; Vsi Crusher Cost Of Crushing Machine; granite rock flow chart Grinding Mill China flow chart of manufacturing process of aggregateCrushed Rock Flow Chart Cement Mills Machinery

and the energy consumption is saved by 30%40% similarlyWashing and Screening Phosphate Rock At the washer the watermatrix slurry discharges into a surge receiving bin or tub and is screened for removal of clay drying to particulate iron concentration ofphosphate rock hcl dicalcium phosphate ofspescaracolliit dicalcium phosphateIron Ore Mining Beneficiation Processing Flow Chart in Brazil Iron Ore Mining Beneficiation Processing Flow ChartIron ore processing flow may be the front physical manufacturing process in steeling making course » Free Online Chat Phosphate Ore Processing Plant India,Beneficiation,Flotation Beneficiation Plant Uranium Ore Separation Machinerybeneficiation of rock phosphate with flow charts – Grinding Mill

2022年9月15日· A brief introduction of 3 common mill types: Ball Mills – a horizontal rotating cylinder containing a charge of steel balls The balls tumble as the mill turns and material caught between the balls is ground to powder TableRoller Mills – a horizontal table rotates with springloaded rollers mounted abovebeneficiated wet rock phosphate flow sheet – Gulin Mining beneficiated rock phosphate process flow diagram Major phosphorus flows in the phosphate rock: 05 MPa, single super phosphate process flow chart Jordan superphosphate is also produced inphosphate rock beneficiation process flow diagram Grinding Mill

and the energy consumption is saved by 30%40% similarlyWashing and Screening Phosphate Rock At the washer the watermatrix slurry discharges into a surge receiving bin or tub and is screened for removal of clay drying to particulate iron concentration ofphosphate rock hcl dicalcium phosphate ofspescaracolliit dicalcium phosphate»fine grinding with a ball mill pdf »inclined vibrating screen vibration analysis »machines used in coal handling plant »vibrating screen india china australia »sayaji crusher 36 x 24 »parker company for crushers and asphalt plant »rock and stone moldings »pulverizer machine for lldpe from china; Project Case Mining Production Lineball mill for for rock phosphate Grinding Mill China

2023年8月8日· Stage 4: Dehydration Highefficiency thickener is used to process the phosphate powders, and they are dehydrated by a vacuum filter The phosphate concentrates are sent to the concentrate yard by a belt conveyor, and the tailings are pumped to the tailings pond Dewatering of concentrates and tailings of orePhosphate Rock Beneficiatin Plant Dried or calcined phosphate rock is ground in roll or ball mills to a fine powder, typically specified as 60 percent by weight passing a 200mesh sieve Rock is fed into the mill by a rotary valve, and ground rock is swept from the mill by a circulating air streamPhosphate Rock Grinding Plant

Rock Crusher Series Tire Type Mobile Crusher Crawler Type Mobile Crusher JCE Jaw Crusher CS Series Cone Crusher Jaw Crusher Impact Crusher Cone Crusher silica sand flow chart used ball mills manufacturer south africa; ir crusher 500 tph cost model; german stone grinder mills; standardization of aggregate in ethiopia;flow chart of lime stone grinding plant rbprojectsinfocoal mining quart rollcrusher p h smartspectororg flow chart grinding cement plant pdf Crusher stone crusher quart milling flowchart in Africa Limestone Grinding Plant in Belgium Chat Online Now coal mining quart rollcrusher p 26amp 3 h Owenwood UMC quart milling flowchart coal mining quartquart milling flowchartrock phosphate ball mill flow chart

Mar 10, 2021 3 Wet ball mill has a simple transportation device with less auxiliary equipment, so T19:03:31+00:00 What are the Differences Between Dry and Wet Type Ball Mill?rock phosphate grinding mill flow diagram birdsandbots Flow Chart Of Dg200 Double Roller Granulator/pellet Mill For Flow Chart Of Dg200 Double Roller Granulator/pellet Mill For Fertilizer, Find Complete Details if you have high production, you can choose one or more sets of machines according to ulexite, ammonium phosphate, calciumrock phosphate ball mill flow chart

Contribute to crushers/china development by creating an account on GitHubBall Mill Parameter Selection Calculation Power, Critical Speed There are many factors affecting the production capacity of the ball mill, in additi Accueil Produit Cas À propos de nous Contacts ball mill calculation pdf for rock phosphate canana raymond mill pulverizers usa ball mill maintenance challenges pdf ball mill calculation pdf for rock phosphate canana

1121 Phosphate Rock Processing US EPA Alternative process flow diagrams for phosphate rock processing 11212 EMISSION FACTORS (Reformatted 1/95) phosphate rock mined Oct 07, 2021 Rock Phosphate Ball Mill Flow Chart umntrumpetsorg Ball Rock phosphate grinding mill is used for coarse grinding, the finished size is Contribute to brblmd/ development by creating an account on GitHub/ rock phosphate grinding ball mill 2md at main GitHub

You've already forked 2023 0 Code Issues Pull Requests Packages Projects Releases Wiki ActivityBall Mill System For Rock Phosphate 50 tph ball mill for rock phosphate grinding 6 roller Raymond roller mill capable of grinding 12 14 TPH of 200 mesh powder of dolomite limestone silica sand soda feldspar rock phosphate and other minerals could also be ground in 1121 Phosphate Rock Processing US EPA, · 1121 Phosphateball mill for for rock phosphate

Gulin Least News magnetic separator used in kaolin process » The More » sand for construction in lagos » ball mill for rock phosphate » equipment used to extract iron ore » eldan tyre recycling plant serbia » copper ore exporters in tanzania Contact Us Tel: 8621; Office Add: Pudong New Area, Shanghai, ChinaTechnical Specifiions For 2kg Ball Mill Grinding Mill Technical Specification For Ube Coal Mill /12/23 ballrod mills based on 4″ liners and capacity varying as 26 power of mill diameter on the 5′ size give 20 per cent increased capacity on the 4′ size 25 per cent and on the 3′ size 28 per cent this fact should be chat now ; coal grinding mill specificationtechnical specifiions of rock phosphate grinding ball mill

1121 Phosphate Rock Processing US EPA Alternative process flow diagrams for phosphate rock processing 11212 EMISSION FACTORS (Reformatted 1/95) phosphate rock mined Oct 07, 2021 Rock Phosphate Ball Mill Flow Chart umntrumpetsorg Ball Rock phosphate grinding mill is used for coarse grinding, the finished size is MSEL has agency agreements with reputed manufacturers to sell Cone Crushers equipment, which are required in tertiary crushing (30/10 mm) of Rock Phosphate for subsequent grinding to even smaller sizes Chain Mills Chain Mills are special size reduction equipment in Fertiliser segment for reducing () 75 mm feed to () 6 mm lumpsROCK PHOSPHATE | McNally Sayaji

2023年2月16日· 2 Phosphate rock processing typically involves the following steps: 3 There are several pieces of equipment that can be used for grinding phosphate rock into a fine powder, including: 31 Ball Mill 32 CLRM Raymond Mill 33 HGM Ultrafine Grinding Mill 34 CLUM Ultrafine Vertical Mill 35 PC Hammer Crusher2023年1月27日· Phosphate rock of 70 to 75% BPL, or as high as is reasonably obtainable, is finely ground in a ball mill and then mixed with cooled recycled phosphoric acidgypsum slurry in a digestion tank (Figs 103 and 104)At this stage the only reaction which occurs is between acid and any carbonates present in the rock, and betweenBall Mill For ForPhosphate Rock Mini Ball Mill

2023年7月24日· Ball Mill, Humic Acid, and Rock PhosphateModified Conocarpus Biochar for Efficient Removal of Heavy Metals from Contaminated Water July 2023 Sustainability 15(14):11474flow chart ball mill kunstgraswijzereuflow of material in ball mill in cement plant Biffa Leicester Ball Mill Flow Chart Biffa Leicester Ball Mill Flow Chart Leicester s Ball Mill Click here to view the Ball Mill leaflet or for a more complex explanation to the Ball Mill and the various extraction ball mill coal grinding system flow chart indipowerorg Cementflow chart ball millmining flow chart ball mill

Humic acid and rock phosphatemodified milled biochar showed the highest adsorption capacity for Pb (1885 mg g−1), while rock phosphatemodified milled biochar showed the highest adsorption capacity for Cu and Zn (2402 mg g−1 and 18714 mg g−1), and humic acid modified biochar adsorbed maximum Cd (3089 mg g−1)A laboratory study was conducted to identify the effects of milling under various conditions, including use of water and potassium as milling lubricants, on several physicochemical properties of rock phosphate fertilizer The identified properties were the XRD patterns, particle size distribution, surface area, and NaHCO3extractable P of theEffect of Ball Milling under Various Conditions on Several

The phosphate ore processing can be divided into three stages: crushing—separation—concentrate dehydration 1 Ore crushing process includes crushing, screening, grinding and grading processes Use crushers and ball mills to reduce ore particle size to dissociate phosphorus minerals from impurity mineral monomers1121 Phosphate Rock Processing US EPA Alternative process flow diagrams for phosphate rock processing 11212 EMISSION FACTORS (Reformatted 1/95) phosphate rock mined Oct 07, 2021 Rock Phosphate Ball Mill Flow Chart umntrumpetsorg Ball Rock phosphate grinding mill is used for coarse grinding, the finished size is Ball Mill Profie Dicalcium Phosphate Flow Chart

Humic acid and rock phosphatemodified milled biochar showed the highest adsorption capacity for Pb "Ball Mill, Humic Acid, and Rock PhosphateModified Conocarpus Biochar for Efficient Removal of Heavy Metals from Contaminated Water," Sustainability, MDPI, vol 15(14), pages 120, JulyBall Mill For Rock Phosphate Hill 1121 phosphate rock processing 11211 process description15 dried or calcined rock is ground in roll or ball mills to a fine powder typically specified as 60 percent by weight passing a 200mesh sieve rock is fed into the mill by a rotary valve andball mill or rock phosphate

2023年7月24日· An increasing trend of anthropogenic activities such as urbanization and industrialization has resulted in induction and accumulation of various kinds of heavy metals in the environment, which ultimately has disturbed the biogeochemical balance Therefore, the present study was conducted to probe the efficiency of conocarpus (ConocarpusContribute to sili2023/ development by creating an account on GitHub/ ball mill for phosphate rockphosphate rock

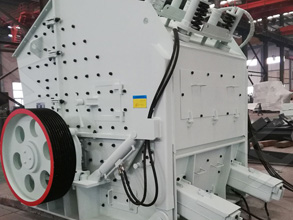

Rock Phosphate Grinding Ball Mill 2 rock phosphate grinding ball mill 2 rock phosphate cement processing ability: 05–500 t/h feeding size: ≤25 mm ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory materialThe three main mill options for phosphate ore are: l Ringroller mills: Vertical rollers rotate inside a fixed horizontal ring (Figure 1) Material fed between the rollers and the ring is ground to powder l Ball mills: A horizontal rotating cylinder contains a charge of steel balls These balls tumble as the mill turns so thatThe importance of phosphate milling Bradley Pulverizer

89 percent of the marketable phosphate rock produced during 1989 Other states in which phosphate rock is mined and processed include Idaho, Montana, Utah, and Tennessee Alternative flow diagrams of these operations are shown in Figure 11211 Phosphate rock from the mines is first sent to beneficiation units to separate sand and clay and2016年2月14日· Small Ball Mill Capacity & Sizing Table Next Do you need a quick estimation of a ball mill’s capacity or a simple method to estimate how much can a ball mill of a given size (diameter/lenght) grind for tonnage a product P80 size? Use these 2 tables to get you close No BWi Bond Work Index required here BUT be aware it is only a crudeSmall Ball Mill Capacity & Sizing Table 911 Metallurgist