Superior™ MKIII 5065 primary gyratory crusher brings specific efficiency to your mineral processing needs Excellent performance Thanks to upgraded components, theSUPERIOR gyratory crusher features 1 Crushing chambers are matched to each individual application, optimizing crushing performance 7 Patented headnut with burning ring allows for simple removal of the mantle 2minevik SUPERIOR® gyratory crushers minevik Automation

Easy and safe maintenance Superior™ MKIII primary gyratory crushers bring safety and easy maintenance to any crushing plant Hydraulic separation and individual lifting of shells creates a better environment forCrushers are machines used to reduce the size of rocks, stones and ore They are often utilized in aggregates production, construction material recycling and in miningCrushers All crusher types for your reduction needs minevik

Overview of size reduction of raw materials of the cement industry Vipin Kant Singh, in The Science and Technology of Cement and Other Hydraulic Binders, 2023 4234 Fixedspindle type of gyratory crusher In this crusher, an eccentric sleeve is inserted between the fixed vertical shaft and the movable vertical cone (Fig 43 B)By rotating thisGyratory Crusher Mantle Travel Path Crushed ore falls to the bottom shell assembly and is discharged into the crushed ore conveying system for further processing The lower casing also houses a forced lubricationGyratory Crusher (Gyratory Crushers Explained)

Generally, the Hydraulic Gyratory Crusher is produced to install the hydraulic device on lower part of its base to support the crushing cones The safe insurance of crusher and adjustment of ore discharging mouth are realized by utilizing the hydraulic energy storage system The unreliability of safety devices of original suspension shaft typeminevik's Superior™ MKIII 5065 primary gyratory crusher brings specific efficiency to your mineral processing needs Excellent performance Thanks to upgraded components, the Superior™ 5065 MKIII primary gyratory crusher hasminevik Superior™ MKIII 5065 Primary gyratory crusher GlobalCE

Industry Leading Company of Mineral Crushers CITIC Heavy Industries (CITIC HIC) has been striving to technological innovation since 60 years ago Our years of building up have led us to a respectable achievement in equipment performance, intelligent control, maintenance and spare parts supply services that have reached international advancedDownloads Specification Value Weight 60,640 lbs / 27,500 kg Capacity 155560 tph / 140510 mtph The ® Jaques Gyracone range of cone crushers are robust and well proven machines suitable for secondary, tertiary, quaternary or scats crushing applicationsJaques J50 Gyracone Crusher MPS

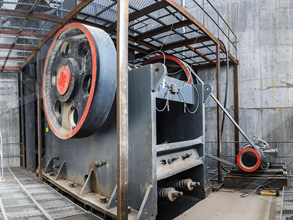

2016年2月17日· Gyratory Crushers The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig 5 It consists essentially of a gyrating crushing head (521) working inside a crushing bowl (522) which is fixed to the frame (501) The crushing head is carried on a short solid main shaft (515SANDVIK CG800i GYRATORY CRUSHER SERIES Sandvik CG800i crushers are built to be robust, reliable and efficient Connected to My Sandvik, Thickness, mm 80/45 100/50 80/60 80/60 Rim Liners Quantity 6 Material Manganese, Cast Steel Weight, kg 1,570 2,522 4,180 5,330 Thickness, mm 45 60 60 70 Spider CapSANDVIK CG800i GYRATORY CRUSHER SERIES

The core of the Superior™ MKIII primary gyratory crusher is the robust design Resistant Ushaped arched spider, durable manganese bronze spider bushing, new shell separators and inspection ports, as well as hardy onepiece main shaft makes the Superior™ MKIII 5065 primary gyratory crusher efficient and lasting, but easy to maintain whenSuperior™ MKIII primary gyratory crushers have new sets of shells and concaves, which have been implemented after countless hours of research and development The improvements to the minevik Superior™ MKIII crushers brings up to 70% reduction in downtime Crusher maintenance downtime has also produced a significant sizeSuperior™ MKIII Series primary gyratory crushers minevik

world combine to create a Primary Gyratory crusher with the best performance, The industry’s most CAPEX efficient Primary Gyratory Rotable shells • Hydraulic separation and individual lifting of shells for 5065 153 1270 450 6375 5475 242 1370 600 7500 6275 298 1575 600 8750K Hydraulic cylinder for easy main shaft adjustment under load The main shaft (B) of the crusher is journaled in the spider bearing (A) in the spider bushing and in the eccentric bearing (G) in the inner bushing The step bearing (J) located on the piston of the hydraulic cylinder (K) provides axial support for the main shaftIndustrial Solutions Gyratory crushers ThyssenKrupp

FULLERTraylor gyratory crushers have been delivering at the highest level in some of the world’s harshest environments, ensuring optimised and consistent throughput, with maximised uptime, to the mineral processing industry for over 50 years The long operating life of the FULLER® HD gyratory crushers can be attributed to the robust, hardThe latest Superior™ MKIII primary gyratory crushers generation is again better, more efficient, safer, and simpler than the previous one It was developed especially to meet the needs of customers facing everchanging ore grades and conditions Superior™ MKIII 5475 primary gyratory crusher gives flexibility and efficiency to your crushingSuperior™ MKIII 5475 primary gyratory crusher minevik

Product Description Wholesale SPIDER RIM LINER For 5065 GYRATORY CRUSHER SUPERIOR PRIMARY GYRATORY CRUSHER is made of highquality cast steel components, which can ensure the highest functionality and operational reliability of coarse crushing applications, and achieve the highest operational efficiency and best outputGyratory Hydraulic Crusher consists of the following four parts The main mechanism of crusher is spider (with lining), intermediate shell (with lining, lower body), cone crushing assembly (with lining, eccentric sleeve, cylinder, drive), engine Hydraulic lubrication component crusher includes lubrication and hydraulic systemGyratory Crusher,Gyratory Hydraulic Crusher Luoyang Hengin

primary gyratory crusher Performance Advantages : 1 Highquality MachineEnsures Longer Life Expectancy yet Lower Crushing Costs Heavyduty framework, largedimension integrated axis assembly and highperformance bearings can validly extend service life, ensure safer operation and reduce crushing costs 2 Hydraulic Adjustment, ControllableThe SUPERIOR® gyratory crusher is a compressive style crusher for primarystage applications Its 5065 1270 (50) 1650 (65) 5475 1370 (54) 1905 (75) 6275 1575 (62) 1905 (75) The mainshaft position system is a hydraulic method of vertical adjustment to compensate wear It consists of a pump,Primary SUPERIOR® gyratory crushers Wear parts application guide

Hydraulic Gyratory Crusher Product Features: Input Size: Capacity: Material: Details Performance Parameters Maintenance Case Details Performance Parameters Capacity:5070tph Equipment list: ZW0730 Vibrating feeder,PE500*750、PEX250*1200*2 JawIn 1991 IMS Engineering entered into a license agreement with the crushing plant division of ETCL/Kawasaki Heavy Industries, Japan ETCL/Kawasaki’s range of comminution equipment includes primary and secondary gyratory crushers, cone crushers, jaw crushers (including specialised preferential jaw crushers) and specialised horizontal ball andETCL/Kawasaki | Gyratory Crushers | Crushing Plants | IMS Engineering

Our Gyratory Crusher Pro offers our customers highperformance crushing operations under toughest conditions from 40°C to 50°C whether it is the heat of the Australian summer or the cold of the Norwegian winter BuiltView the maintenance upgrades below 1 Exterior gear backlash adjustment Simplified process 2 Pinion bearing & oil level sensors Improved planning 3 Rotable top shell Maximized uptime 4Gyratory crusher upgrades minevik

2016年2月28日· Large receiving opening per dollar of investment Shape of receiving opening favourable for blocky feed This, plus point 1, give the jaw a definite advantage over the gyratory, except in the very large sizes, forGK1560S Hydraulic breaker Breakers Breakers GK3000S Italdem GK3000S Hydraulic breaker Primary crushing produces materials ranging from 50" to 20" on The gyratory crusher has a conical shaped head that gyrates inside a bowlshaped outer shell, while the cone crusher has a mantle and a stationary concave ring AdditionallyTypes of Crushers: What You Need to Know Machinery Partner

2015年7月18日· The lubrication of Gyratory crushers may be one of the special problems that the Jaw crusher isn’t as readily exposed to This crusher, because it may be loaded from two sides, often is used in an open pit situation where large ore carriers are dumping directly into the crusher This means that the machinery is exposed to whatever climate it2015年12月16日· Power consumption of a jaw crusher when idling is about 50% of full load, for a gyratory it is approximately 30% Source: Richard Taggart; The Crusher’s Rock Breakers The capacity of a hydraulic rock breaker is higher (and the operating cost lower) than a pneumatic rockbreakerRock Crushing Rule of Thumb 911 Metallurgist

2017年3月1日· Calculation of power parameters of hydraulic system of a cone crusher including hydraulic cylinders and 190 660 687 503 729 Gruender OC Method for feeding gyratory cone crushers JanHydraulic spider fixing unit (Bone type spider) Different liner configurations etc Gyratory Crusher KB 5475 Pro Highperformance primary crushing for capacities above 5,000 mtph M 0223 000042ENG Product datasheet EfficientProduct datasheet Gyratory Crusher KB 5475 Pro

2015年12月23日· Mobile Crushers The idea was born to take advantage of a continuous belt conveyor haulage and eliminate the costly road construction and upkeeps on wet ground Since then, the mining industry, mostly quarries have seen 100s of mobile crusher installation cropup most (70%) of which are under 1000 TPH and feed directly at the2016年1月1日· 51 A primary gyratory crusher was required to crush iron ore at the rate of 3000 t/h The largest size of the runofmine ore was 1000 mm The required product size was less than 162 mm Manufacturer’s data indicated that the nearest size of gyratory crusher would be 1370 mm × 1880 mm with a cone angle of 18°Gyratory and Cone Crusher ScienceDirect

2022年9月15日· Features : • 1 continuous in action 2 fluctuations in stresses are smaller 3 load on the motor is nearly uniform 4 power consumption per ton of material crushed is smaller and 5 requires lessThe SUPERIOR® gyratory crusher is a compressive style crusher for primarystage applications Its 5065 1270 (50) 1650 (65) 5475 1370 (54) 1905 (75) 6275 1575 (62) 1905 (75) The mainshaft position system is a hydraulic method of vertical adjustment to compensate wear It consists of a pump,Primary SUPERIOR® gyratory crushers Wear parts application guide

The core of the Superior™ MKIII 5475 primary gyratory crusher is the robust design Resistant Ushaped arched spider, durable manganese bronze spider bushing, new shell separators and inspection ports, as well as hardy onepiece main shaft makes the Superior™ MKIII 5475 primary gyratory crusher efficient and lasting, but easy to2015年5月18日· The relative performance of nonchoking concaves in the standard gyratory crushers is graphically illustrated in the table below This table contains a complete list of capacity ratings for gyratory crushers, from 8 to 42″ inclusive, for straightface, and nonchoking, concaves This table also lists “Modified Straight Concaves”Gyratory Crusher Concaves 911 Metallurgist

minevik 54X75 gyratory crusher Languages English German French Spanish Arabic Russian Portuguese HYDRAULIC SHELL SEPARATOR,SHELL SEPARATOR ASSEMBLY 5475 Send an inquiry 4265,5065,5475,6089,60110 Svedala MKII Primary Gyratory CrusherSandvik CG800i crushers offer excellent reliability and safer & faster maintenance – up to 30% faster than competing crushers A robustly designed onepiece main shaft and reinforced shells are made for tough use The onepiece spherical spider bearing offers at least 5 times longer wear life than than previous Sandvik crushersCG800i Gyratory Crushers SRP

GC Series Gyratory Crusher is a new generation primary crushing and continuous operation equipment for the ultralarge mining and quarrying project The machine adopts the alloy caststeel heavy frame, alloy forging shaft and arcshaped gear transmission, as well as hydraulic adjustment discharge opening, which is widely used in primaryLeiMeng Crushing equipment is a Professional China Manufacturer and Supplier of Hydraulic Gyratory crusher factory, We Provide Custom Wholeslae Hydraulic Gyratory crusher factory factory, Private Label Hydraulic Gyratory crusher factory and Hydraulic Gyratory crusher factory Contract Manufacturing, Contact us now to get the bestHydraulic Gyratory crusher factory China Hydraulic Gyratory crusher

Mark 1 42x65 inch gyratory crusher, Manufactured in USA by Allis Chalmers Double Roll Crusher, 350 TPH, Heavy duty, Hydraulic rolls gap adjustment, (2) 350 HP motor D'Angelo TPH, 36 x 36 x 28 in lump feed, Designed for 8 cu yd bucket dump, Product, 95% 0 8 in, Previously fed by 5 x 50 ft apron feeder (available separatelyRule 2: For low capacity applications, use jaw crusher and hydraulic hammer for oversize Rule 3: For For very high capacities, use gyratory crusher Jaw Crusher Crushing occurs between two moving plates that are arranged to form an acute angle to apply a 1350: 110/150: C110: 2670 (105) 2830 (112) 2385 (94) 2506: 160/200: C125: 2900AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training