2021年1月10日· Secondary crushing, as you can imagine, is the second stage of material processing following its initial reduction At this stage, material will flow through perhaps2016年2月28日· The term “ secondary crushing ” has become well established and familiar through long usage; it applies to the crushing stage, either single or multiple, whichSecondary Crushing Equipment 911 Metallurgist

Applications: Secondary medium & fine crusher is widely used in mining, quarry, mixing and batching plant, road and building construction, highway, railway and subway, and2023年2月28日· Secondary crushing is commonly used in the aggregates industry for producing crushed stone and gravel It is also used in the mining industry for processing ores and minerals Differences betweenThe Complete Guide to Primary Crushing, Secondary

A crusher is a machine that reduces large rocks into smaller rocks, gravel, or rock dust Crushers are mainly used in the mining and construction industries, where they are usedApril 2021 | Features Cone crushing often provides the most economic and reliable method for secondary crushing in mineral processing applications (Photo: thyssenkrupp) E&MJPerfecting the Performance of Secondary Crushers | E & MJ

2023年2月28日· Secondary crushers are machines that are used to break down large rocks into smaller, more manageable pieces They are an essential part of the mining2014年1月17日· ANOVA test of energy consumption values of the secondary crusher Full size image As shown in Table 3, specific charge values used for the Aravadi limestoneDevelopment of a model estimating energy consumption

Definition of secondary crusher Crushing and pulverizing machines next in line after the primary crushing to further reduce the particle size of shale or other rock All types of jawRoll crushers can be used for both primary and secondary crushing, depending on the application Hammer Mills: Hammer mills use rotating hammers to crush the mineral samples against a stationary grinding surface They are ideal for crushing soft to mediumhard materials, producing a fine output size suitable for analysis laboratory type hammerLaboratory Crushers and Pulverizers Unal Lab Machinery

Primary crushing operations takes boulder size feeds (20 to 100 inches) and reduces the material to secondary crusher feed size (1 to 20 inches) or mill feed size (05 to 3 inches) This video illustrates single and Main useMore crushers added daily from manufacturers such as Caterpillar, Case, John Deere, Komatsu, JCB, Bobcat and more Check back often or create a free account and save your search to receive notifications whenNew and used Crushers for sale | Ritchie Bros

Nov 28, 2011 Tokyo, November 28, 2011 ― EarthTechnica Co, Ltd, a whollyowned subsidiary of Kawasaki Heavy Industries, Ltd, announced today that it will launch a new cone crusher, the REXE Cone, on December 1 The REXE Cone is a gyratory type secondary crusher used in the production of concrete aggregates for further reducing6693 Crushed nest is the result of using a pestle and mortar on an empty bird nest They are used to make Saradomin brews Wesley (in Nardah) will crush unnoted or noted herblore secondary items for 50 coins per itemCrushed nest OSRS Wiki

® GP300S™ secondary cone crusher is designed for economic and efficient size reduction in secondary crushing applications It is often used in aggregates production, and in mining operations ® GP300S™ secondary cone crusher’s heavyduty design and use of highquality components with optimized wear parts keep the2023年12月29日· A secondary crusher is a machine that is used after primary crushing to reduce the size of the material further Primary crushing is typically done in a jaw crusher or gyratory crusher, and theWhat is the function of the secondary crusher? LinkedIn

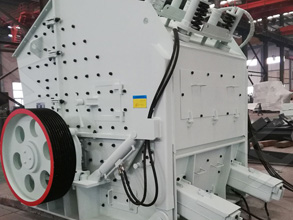

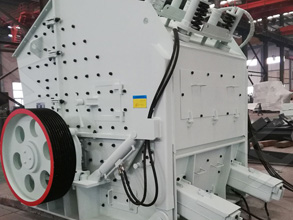

They can be used in coal, salt, coke, glass, and trona operations, among others Triple Roll Crushers combine a Single Roll Crusher with a Double Roll Crusher to form a crusher that is capable of achieving a 6:1 reduction ratio in the primary stage and a 4:1 reduction in the secondary stage while producing a cubicle product at high capacityThe rotor is the ‘heart’ of a secondary impact crusher, and the strength of this key component is tested relentlessly by the crushing process Throughout ’s experience of over 70 years of in the industry, special emphasis has always been placed on rotor design, development, and the field of applicationSecondary Impact Crusher | HSI

2023年2月28日· Learn about the different types of secondary crushers, including impact crushers, cone crushers, roll crushers, and jaw crushers, and their functions, advantages, disadvantages, applications, and factors to consider when selecting them Discover case studies and examples of successful applications, as well as future developments in2013年3月12日· Three in One Mobile Crusher limestone mobile crushing plant used in Qatar South Africa 30 tph limestone grinding plant Limestone grinding line in Kazan Russia South Africa 200 tph granite crushing line Philippines 150TPH Riverstone Crushing Plant Indonesia 180 tph Iron Ore crushing plant How Much VSI Sand Crushersecondary crushing | Mining & Quarry Plant

The roll crusher consists of a pair of horizontal cylindrical manganese steel spring rolls (Fig 1314), which rotate in opposite directions The falling feed material is squeezed and crushed between the rollers The final product passes through the discharge point This type of crusher is used in secondary or tertiary crushing applications2022年6月1日· Secara riwayat, salah satu Secondary Crusher yang lama Di CPP Site Binungan CR11 membutuhkan biaya perawatan yang tinggi dan kinerja yang tidak sesuai dengan kebutuhan produksi sebesar 1500 ton(PDF) ANALISA KELAYAKAN INVESTASI PROYEK PENGGANTIAN SECONDARY CRUSHER

2016年1月16日· The use of hammer mills is in the field of softer minerals, such as gypsum, barytes and limestone, and particularly where the presence of clay would most definitely exclude the use of crushing machines in which fracture of the mineral is effected by pressure In this latter field in particular, the hammer mill is also used as a primary crusher2020年5月6日· Common types of Impact Crushers are Horizontal Shaft Impactor (HSI) and Vertical Shaft Impactor (VSI) The new hybrid models of impact crusher are engineered for maximum feed size, target output size, and total capacity The newer models are capable of producing constructiongrade aggregate, artificial sand and stone materials, run of mineDifferent types of crushing equipments Constro Facilitator

2014年2月1日· crusher, secondary crusher, tertiary cr usher, and two crawle r crushers at this cr ushing facili ty The ore coming fr om the quarry is pass ed from the gr id with a cleara nce of 150 mm andFeatures ® GP500S™ secondary cone crusher is engineered for economic and efficient size reduction in secondary crushing applications It is often used in aggregates production and mining operations The crusher’s heavyduty design and use of highquality components with optimized wear parts keep the operating costs down® GP500S™ secondary cone crusher minevik

2021年1月16日· secondary impact crusher | 3D CAD Model Library | GrabCAD Join 9,250,000 engineers with over 4,800,000 free CAD files Join the Community The CAD files and renderings posted to this website are created, uploaded and managed by thirdparty community members This content and associated text is in no way sponsored by orjaw crusher 1 PMCC2 mobile compact fine Capacity: 120 t/h 150 t/h Motor power: 350 kW Opening height: 850 mm Introducing the Polygonmach PMCC2, a gamechanging mobile crushing and screening plant on wheels with an impressive production capacity of 120150 tph, depending on the material's hardness gradeSecondary crusher, Secondary crushing and screening plant All

Ideally, the deck on the scalping screen should have a cut point equal to the closed side setting (CSS) of the crusher The feed size to a secondary crusher is typically in the range of 50 mm to 250 mm (up to 300 mm) If the capacity is higher, the acceptable feed size gets larger After crushing, the product is in the range of 060 mm (75 mmGP100S™ crusher is an excellent choice whenever high reduction, firstclass cubicity or great capacity is required The optimized design of the ® GP100S™ castings makes it possible to use a higher power rating than any other cone crusher with an equal head diameter Cavity designs provide maximum yields for required highquality® GP100S™ secondary cone crusher minevik

typically located next to a crusher to reduce oversize material too large for a crusher Crushers are used to reduce particle size enough so that the material can be processed into finer particles in a grinder A typical processing line at a mine might consist of a crusher followed by a SAG mill followed by a ball mill In this context, the SAG2015年7月24日· Our last schematic represents a CLOSED CIRCUIT This one involves both SECONDARY and TERTIARY crushing This circuit is employed where either the tonnage or the work index of the ore is highSecondary & Tertiary Crushing Circuits 911

A primary crusher breaks up large pieces of rock or concrete from the blasting or excavation process and turns them into smaller, more manageable chunks This is the first step in the crushing process The smaller pieces can then either be prescreened or fed directly into a secondary impact or cone crusherYour #1 source in USA and Canada for Cone Crushers used in the mining industry All sizes available including cone parts From Symons, , Sandvik and more! go to top Skip to Bare 52 inch crusher, Secondary or tertiary crusher, Hydraulic adjust cone, Hstyle machine, Medium liners, Lubrication tank and pump, OilUsed Cone Crushers for Sale | Surplus Record

Primary and Secondary Sizers are sized and selected based on the specific material and lump size to be crushed Tooth profile selection allows the material to be grabbed and pulled into the crushing zone for maximum efficiency Sizers use an electric motor to drive the gear reducer, which is mounted directly to the crushing shaft6 天之前· Fine jaw crusher, mainly used for secondary crushing, feed 25cm belowProduction of crushers, mobile crushing stations, vibrating screens, screening machinesFine jaw crusher, mainly used for secondary crushing, feed

2021年1月16日· secondary impact crusher Necati KARAKUVAT January 16th, 2021 Sekonder Darbeli KırıcCone crushers have gained such wide acceptance that they may be regarded as standard in the intermediaterange sizereducing machines A schematic diagram of a cone crusher is shown in Fig 46 AThe drive is similar to that of a gyratory crusher The inner cone or ‘crushing head’ is supported by the tapered concentric spindle, which is rotated by theCone Crusher an overview | ScienceDirect Topics

Secondary Impact Crusher MEKA MSI Series Secondary Impact Crusher is ideally suited to crush soft to medium hard materials down to a highly cubical, well graded product size of 080 mm in a single pass Although this crusher is normally offered within a plant where tertiary crushing is also present, due to its high reduction ratio, the needThe roll crusher consists of a pair of horizontal cylindrical manganese steel spring rolls (Fig 1314), which rotate in opposite directions The falling feed material is squeezed and crushed between the rollers The final product passes through the discharge point This type of crusher is used in secondary or tertiary crushing applicationsCrusher an overview | ScienceDirect Topics

Hammer crushers are used either as a onestep primary crusher or as a secondary crusher for products from a primary crusher They are widely used for crushing hard metal scrap for different hard metal recycling processes Pivoted hammers are pendulous, mounted on the horizontal axes symmetrically located along the perimeter of a rotor2023年2月2日· A tertiary crusher is a type of crusher used in the mining industry to process rocks, ores, and other materials into smaller sizes It is typically used after a secondary crusher and is capable ofWhat is a tertiary crusher? LinkedIn

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above Compressionstyle jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types 2 Secondary Crushing6693 Crushed nest is the result of using a pestle and mortar on an empty bird nest They are used to make Saradomin brews Wesley (in Nardah) will crush unnoted or noted herblore secondary items for 50 coins per itemCrushed nest OSRS Wiki

2022年6月1日· Secara riwayat, salah satu Secondary Crusher yang lama Di CPP Site Binungan CR11 membutuhkan biaya perawatan yang tinggi dan kinerja yang tidak sesuai dengan kebutuhan produksi sebesar 1500 tonGP100S™ crusher is an excellent choice whenever high reduction, firstclass cubicity or great capacity is required The optimized design of the ® GP100S™ castings makes it possible to use a higher power rating than any other cone crusher with an equal head diameter Cavity designs provide maximum yields for required highquality® GP100S™ secondary cone crusher minevik

USA and Canada's #1 source for used and surplus crushers for the mining and minerals All types available and in stock from mining equipment dealers near you Used 5HP 15"x9" American Pulverizer Crusher Type L Ring Hammer Mill, Rotor size: 15" X 9" wide, Power required: 230/460 VAC, 60Hz, 3 phase, Shipping info:For the sedimentary rocks (Siltstone) the specific crushing energy is approximately 126 kJ/kg Tosun and Konak (2014) measured power consumption of jaw crusher during crushing of limestone rocksEnergy consumption values of each crusher per tonne

2023年2月15日· A highquality hammer crusher can keep final material 100% passing a twenty mesh, fifty to sixty percent passing a fiftymesh screen Crusher hammers are high chrome content The hammer service life depends on the material you process If you're running abrasive quartz, they'll last somewhere between one to two weeks